Why use clean room dedicated floor drain?

With the publication of the latest GMP specification in 2010 and the close technical exchange of domestic and foreign pharmaceutical industries, the pharmaceutical industry pays more and more attention to the professionalization and refinement of purification equipment and parts. Recently, the problems in drug and food quality has begun to be curbed, and set higher standards on the production. Most water seals of floor drains used in the clean rooms couldn’t meet the GMP requirements on drainage, excavation, overflow, moth-prevention and deodorization.

The dedicated floor drain is designed for clean rooms and sterile rooms, and improved the design according to the latest GMP. It successfully solves the technical problems in drainage, excavation, water seal, air seal, spray-cooling of mixed water &vapor flow and new high-water seal floor drain. It is dedicated for purification workshops and clean rooms (new GMP certification). The product is made of 304# or 316L stainless steel.

Features

- Made of full stainless steel,smooth and bright surface;

- Use blank-door type handle as surface cover to ensure it is flush with floor;

- Use double-sealing (air sealing and water sealing) to ensure excellent sealing;

- Acid and alkali resistant,corrosion resistant,waterproof to eusure long service life

Models of clean room dedicated floor drains

DN50, DN75, DN100

Instructions

1. After washing the clean floor drain, only need to fill appropriate amount of disinfectant into the floor drain to ensure clean production environment;

2. To wash the removable floor drain, pull out the drain pipe, empty the sewage, wash thoroughly and put it back; No dead corner for sanitation, used for sterile room drainage.

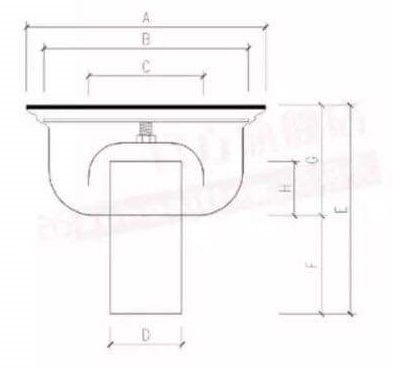

Specifications

| A | B | C | D | E | F | G | H | |

| DN-50 | 132 | 105 | 80 | 48 | 138 | 65 | 75 | 50 |

| DN-75 | 157 | 145 | 100 | 75 | 157 | 65 | 87 | 50 |

| DN-100 | 204 | 181 | 150 | 100 | 155 | 65 | 92 | 50 |