Wash basin sink

Cleanroom hand wash basin sink is a device that is installed and used a lot in production facilities and laboratories. Because of the strict requirements on the level of hygiene in a clean environment, employees are required to completely remove bacteria on their bodies, especially their hands, before entering the clean room area.

Cleanroom hand wash basins are usually made from 304 or 316 stainless steel, with polished surfaces that are durable and easy to install and clean.

The sink can be designed according to customer's needs (the number of sinks, drains, and faucets...)

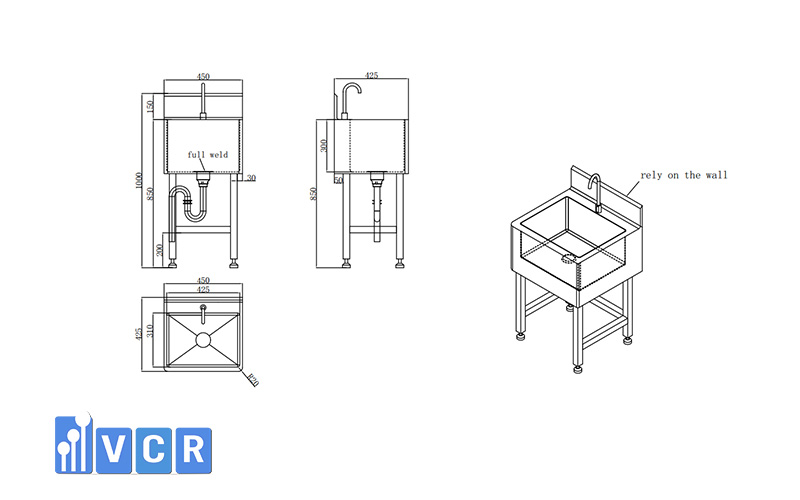

Dimensions

The dimensions listed are for reference only. All products can be customized according to customer requirements.

|

Dimensions |

Half Cover Single Sink |

Full Cover Single Sink |

|

Overall size (LxWxH) (mm) |

450x425x1000 |

450x425x1000 |

|

Sink size (mm) |

425*310 |

425*310 |

|

Depth of the sink (mm) |

300 |

300 |

|

Material |

304 or 316 non-magnetic stainless steel |

304 or 316 non-magnetic stainless steel |

|

Material thickness (mm) |

1.2 |

1.2 |

|

Sink legs (mm) |

38x38x1.5 |

Wash basin sink structure

- The trolleys come with one, two, three or four compartments, multi sizes for option.

- Features square-corner construction in fully welded, access via a front door with door handle. No extra installation.

- Backsplash, drain boards, overflow hole, and faucets for options.

- It is ideally suited for customer with ultra hygiene standards and is easy to clean

Wash basin sink features

- Manufactured from 304 or 316 grade high quality stainless steel.

- Brushed dull polish finish.

- Fully welded construction.

- Crevice free, easy clean surfaces and sturdy design.

- Number of sinks for option.

- Back splash available.

- Upstand strainer available.

- Drains board for option.

- Overflow hole for option.

- Available with various tap options(taps sold separately)

Wash basin sink application

Cleanroom hand wash basin sink is often used to sanitize hands before entering production areas. The sink is designed to be sturdy, and easy to clean, the welds are treated with anti-oxidation.

- Domestic and export food production and processing industry

- Laboratory

- Hospitals

- Health facilities

- Cosmetic Clinic

- Operating rooms