Six sigma application in pharma industry

1.What is 6 sigma? 6 sigma is a methodology that helps companies eleminate defects and improve business process, thereby boosting their products quality and profits. It was developed by Motorola with the aim of achieveing fewer defects in parts

1. What is Six sigma?

Six Sigma is a methodology that helps companies eliminate defects and improve business processes, thereby boosting their product's quality and profits. It was developed by Motorola with the aim of achieving fewer defects in parts manufacturing to other aspects of business like sales, marketing, etc.

Six Sigma employs a statistical method to measure the defects and improve them. It emphasizes cycle-time improvements while reducing to no more than 3.4 defects per million opportunities. This means that a process is considered to be efficient if it produces less than 3.4 defects per one million products.

In practical conditions, a Six Sigma process can produce 99.99966% of opportunities free of defects. It’s important to think that a defect is a product that failed to meet customer expectations. Trying to reach the Six Sigma level, you have a high probability of producing items that are excellent in the eyes of customers.

There are several sigma levels, each of which indicates the number of allowed defects per million, as is shown in the table below.

| Sigma level | Defects per Million | Defects % |

| 1 | 691 462 | 69% |

| 2 | 308 538 | 31% |

| 3 | 66 807 | 6.7% |

| 4 | 6 210 | 0.67% |

| 5 | 233 | 0.023% |

| 6 | 3.4 | 0.00034% |

Lean Six Sigma

Lean Six Sigma is a combination of LEAN management principles with Six Sigma methodologies. Lean focuses on reducing waste and promoting production cycle time, while Six sigma eliminates process variation and enhances process control. Lean Six Sigma is more widely-used because the production process requires both approaches to achieve positive results.

2. The Six Sigma Tool

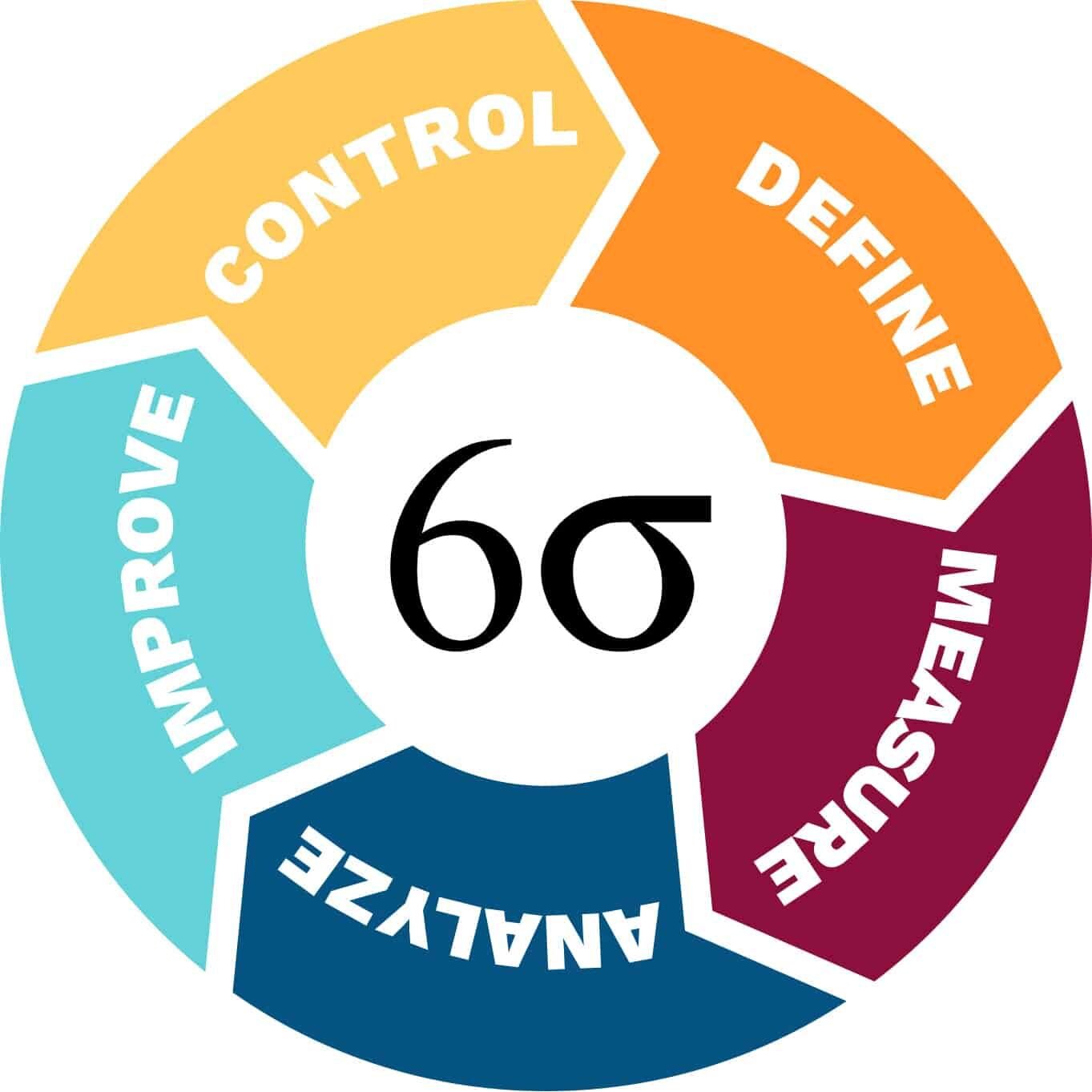

Six Sigma is executed through an approach called DMAIC. This acronym stands for define, measure, analyze, improve and control.

D: Define a faulty process on which to focus based on customer needs and company goals

M: Measure the aspects of the current process

A: Analyze data to identify the reason for process errors.

I: Improve the process.

C: Control the process to ensure that it does not become inefficient again.

3. Six Sigma in pharma industry

Six Sigma is a manufacturing method that involves identifying the defects that cause poor-quality products. This method not only identifies those defects but also eliminates them. As a result, the working efficiency and product quality can be significantly improved. Therefore, the implementation of Six Sigma in the Pharmaceutical industry is a must to improve product quality.

The Six Sigma methodology is based on the identification and definition of problems in the manufacturing process. In addition, this method involves measuring and analyzing data to find errors in the manufacturing process. This will optimize the quality control systems in the manufacturing process, thereby increasing production efficiency and innovation, and reducing cycle times.

By implementing Six Sigma techniques, the pharmaceutical industry can improve the manufacturing process and can successfully perform the same as other industries.

Six Sigma has tools that make the manufacturing process smoother by eliminating mistakes that occur in the process. These tools are not only simple for employees to grasp but also play a similar role in quality assurance and risk management.

Moreover, the six sigma approach makes it easier for pharmaceutical companies to determine the quality at the end of the manufacturing process.

The implementation of Six Sigma in the pharmaceutical industry helps:

- Prevent defective products

- Reduce production cycle time

- Facilitate continuous process improvement

- Increase automation

4. How to implement Six Sigma in pharma industry

The implementation of six sigma in pharmaceuticals is done in different ways.

First, companies require new employees to have Six Sigma certification. This certification shows that operators have the necessary knowledge on how to run an efficient production process. Certified employees are more productive not only because they reduce waste, but also work more efficiently.

Second, pharmaceutical companies need to enroll in courses on six sigma. It shows that most of the senior employees in these companies achieve 6 sigma certification and thus improve their performance in the workplace.

Last but not least, companies need to send their employees to Six sigma training organizations. Six Sigma has helped pharmaceutical companies not only to debug the manufacturing process but also to improve the quality of their output. Thereby, pharmaceutical businesses are able to increase profits.

Example of six sigma:

The Lean Six Sigma (LSS) principle allows pharmacies to improve their processes to improve the quality for their customers. A department that doesn't need a lot of resources and expertise to implement LSS principles and reap the rewards. The creative use of willing volunteers can produce results quickly. The application of LSS will increase employee satisfaction, creating excitement for future improvement.

5. Six sigma principles in pharma industry

Here are the principles when applying LSS in the pharmaceutical industry:

- Identify the problems you want to solve or the process you want to improve

- With increased support from management, individuals are also willing to join the team

- Work in team

- Need a clear understanding of the current working process

- Proceed according to the Gemba walking method (observing the working process)

- Understand value stream

- Put the customer first

- Choose solutions based on high-impact predictions.

- Flexible change

- Make sure there are rules of liability

- Continue to promote quality improvement