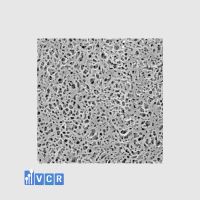

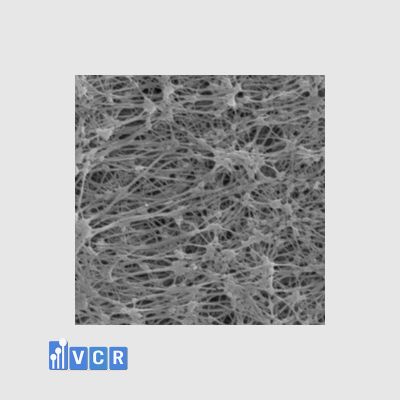

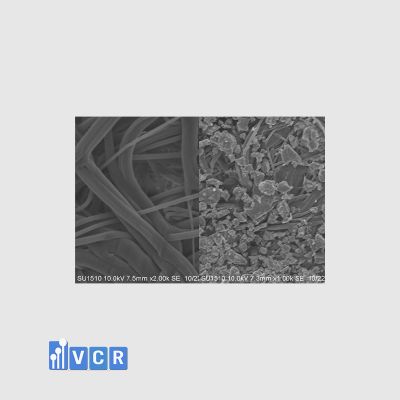

PVDF Membrane

Hydrophilic Polyvinylidene Difluoride (PVDF) membranes are made of polypropylene fibers, controlled and require no binders or surfactants

Hydrophilic Polyvinylidene Difluoride (PVDF) membrane is made from polypropylene fibers, is controlled, and requires no binding agents or surface-active substances.

PVDF Membrane Features

- Excellent high-temp resistance and extensive chemical compatibility.

- Low protein adsorption performance, suitable for filtration of culture solution, biological reagent and aseptic vaccine.

- The samples of filter cartridges successfully passed the bacterial retention testing required by regulations, LRV>7. Integrity can be maintained after repeated disinfection.

- Each filter cartridge should pass the integrity test before leaving the factory. The limitations of integrity testing were correlated with the results of bacterial retention testing.

- All the compositions meet the requirements of the biological testing characteristics of USP Class 6 plastic products at 121°C and the food contact materials listed in the relevant regulations of Chapter 21 of the Federal Regulations of the United States (CFR).

- It is manufactured under ISO 9001 and ISO 14001 systems and Class 100 clean environment.

- Production and usage are traceable.

PVDF Membrane Dimensions

| Membrane |

Hydrophilic polyvinylidene Difluoride (PVDF) |

|

Supports/Diversion |

PP |

|

Filtration area |

Single 10″ filter element is about 0.65m² |

|

Removal Ratings (µm) |

0.22, 0.45 (µm) |

PVDF Membrane Applications

- Industrial water filtration, drinking water, etc.

- In the medical and pharmaceutical industry: biological drug testing, vaccines, sterilization of antibiotic solutions, etc.

- Environmental culture medium filtration.

- In the food industry and recycling materials, etc.

CONTACT TO BUY at 090.123.9008 (call/viber/zalo 24/7)

Other Pleated Filter Cartridge are available at VCR.