PTFE Membrane

Polytetrafluoroethylene (PTFE) is a synthetic fluoropolymer of tetrafluoroethylene with many applications.

Polytetrafluoroethylene (PTFE) is a synthetic fluoropolymer of tetrafluoroethylene with numerous applications.

PTFE has the lowest coefficient of friction compared to other solids. Because of this property, it is used as a non-stick coating for pans and cooking utensils. PTFE is non-reactive chemically, partly due to the strength of the carbon-fluorine bonds, and it is commonly used in containers, piping systems for reactive chemicals, and corrosives.

When used as a lubricant, PTFE reduces friction, wear, and machine energy consumption. PTFE membrane filters are among the most effective filters used in industrial applications, dust collection systems to collect particulate matter from air streams in high-temperature, high particulate load applications, such as coal-fired power plants, cement manufacturing, and steel casting.

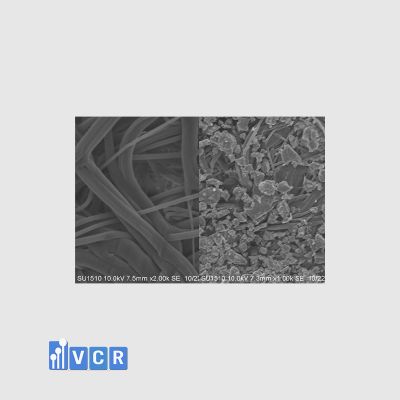

PTFE membrane filters come in two types: hydrophobic (DEPTFE) and hydrophilic (DIPTFE).

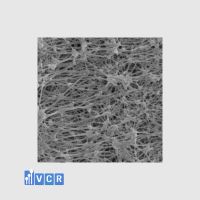

- DEPTFE membrane is made from naturally hydrophobic polytetrafluoroethylene (PTFE) and polypropylene fibers.

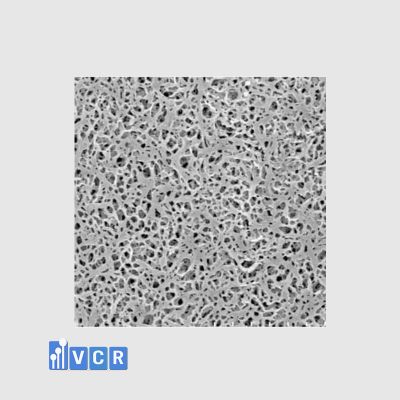

- DIPTFE membrane is made from imported hydrophilically modified polytetrafluoroethylene (PTFE).

PTFE Membrane Features

- Good heat resistance

- Its wide chemical compatibility makes it a highly versatile filter for laboratory use. The durability and properties of PTFE make it capable of filtering harsh liquids in experiments and gases to protect both people and expensive equipment.

- All products meet the requirements for biological testing properties of USP Class VI plastics at 121°C.

- It has good chemical stability and retains dirt effectively.

- PTFE filter membranes excel in delivering suitable and reliable results.

- Every filter element must pass an integrity test before leaving the factory.

- Manufactured to ISO 9001, ISO 14001 standards, and Class 100 cleanroom environment.

PTFE Membrane Dimensions

|

Type |

DEPTFE – Hydrophobic |

DIPTFE – Hydrophilic |

|

Filter material |

Hydrophobic PTFE (DEPTFE) membrane |

Hydrophilic PTFE (DIPTFE) membrane |

|

Supports/Diversion |

PP |

|

|

Filtration Area |

Single 10″ filter element is about 0.65m² |

|

|

Pore size |

0.1, 0.22, 0.45um |

|

PTFE Membrane Applications

|

DEPTFE – Hydrophobic |

DIPTFE – Hydrophilicity |

|

|

CONTACT TO BUY at 090.123.9008 (call/viber/zalo 24/7)

Other Pleated Filter Cartridge are available at VCR.