Sampling Booth Class A

The Pharmaceutical Sampling Booth is used for sample weighing and material division in pharmaceutical, food, cosmetic, and other manufacturing plants.

Sampling Booth is an indispensable device for weighing and sampling operations in pharmaceutical, chemical, food, and cosmetic industries.

Overview of Sampling Booth

Sampling Booth is designed to create a controlled environment for weighing and dividing samples, ensuring the safety of the samples and operators while preventing cross-contamination with the external environment.

Other names for this equipment include Dispensing Booth, Downflow Booth, and Weighing Booth.

Applications of Sampling Booth

Creating a completely sterile environment for sample weighing, dispensing, and other purposes to meet the requirements of experts in the field.

Used in industries such as:

-

- Pharmaceutical Industry

- Chemical Industry

- Food Industry

- Cosmetic Industry

Requirements for Sampling Booth

Used in environments with strict cleanliness and contamination control requirements, LAF equipment needs to meet the following standards:

Cleanliness class A according to GMP (at least as per WHO GMP), with requirements such as:

-

-

- Particle size ≥ 0.5 micrometers (particles/m³) should be 3,520 particles.

- Particle size ≥ 5.0 micrometers (particles/m³) should be 20 particles.

- Total viable microorganisms, molds, and yeast should be less than 1.

- Air velocity should fluctuate within the range of 0.45 ±20% m/s.

-

Laminar Flow air distribution.

Negative pressure: Negative pressure protects operators and prevents cross-contamination with the external environment.

Technical Specifications of Sampling Booth

Below is a table of common dimensions and power specifications for Sampling Booth that you can refer to:

| Information | Description |

|---|---|

| External Dimensions | See the table below |

| Working Area Dimensions | See the table below |

| Material | Inox 304 or Inox 316 chosen |

| Filters | Pre Filter: G4, size > 10 µm Medium Filter: F8 bag filter, size > 5 µm HEPA Filter: HEPA H13 - H14, size > 0.3 µm |

| Air Velocity | Approximately 0.45±20% m/s, creating downward airflow in the working area |

| Noise Level | Below 70 dB to ensure minimal noise disturbance |

| Fan | Rosen - Germany (refer to power specifications in the table below) |

| Lighting | Lighting for the working area |

| DOP Ports | 2 ports |

| Control System | PLC programming, LCD screen, SIEMENS |

| Sensors | Air velocity, Temperature, Humidity |

| Differential Pressure Gauge | Dwyer - 0-125Pa; 0-250Pa; 0-500Pa |

Below is a table of common dimensions and power specifications for Sampling Booth that you can refer to:

| Model | External Dimensions (mm) | Working Area Dimensions (mm) | Air Velocity (m/s) | Power (KW) |

|---|---|---|---|---|

| LWR 13-120060 | 1300×1200×2570 | 1200×600×2000 | 0.45±20% | 0.8 |

| LWR 34-150120 | 1600×1800×2570 | 1500×1200×2000 | - | 2 |

| LWR 75-20020 | 2100×2800×2570 | 2000×2000×2000 | - | 4 |

| LWR 112-300200 | 3100×2800×2570 | 3000×2000×2000 | - | 4 |

| LWR 186-400250 | 4100×3300×2570 | 4000×2500×2000 | - | 7.5 |

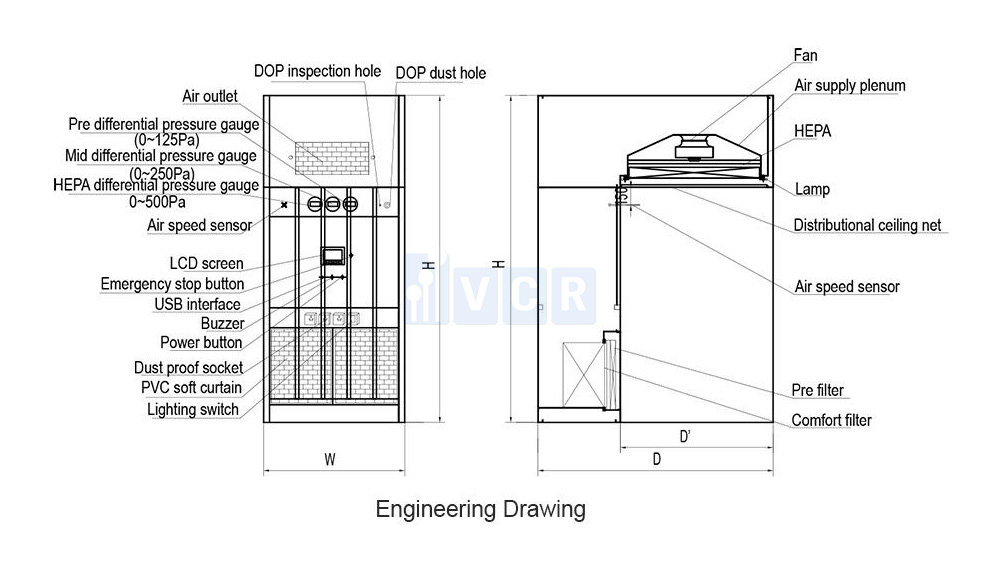

Technical drawings:

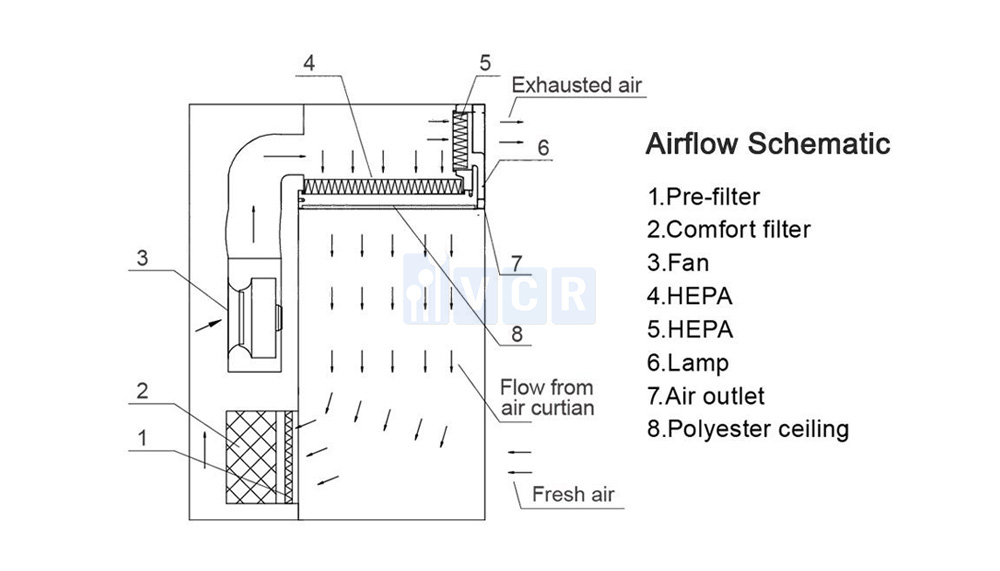

Operating Principle of Sampling Booth VCR

Sampling Booth operates based on the following principle: A fan installed within the air filtration system draws and pushes air through the working area via the HEPA Filter located above. The airflow passing through the HEPA Filter creates a downward laminar flow towards the working area within the weighing booth. Subsequently, the airflow is drawn back into the air filtration system, passing through the coarse and F8 bag filters.

With this airflow principle, Sampling Booth generate a downward laminar flow and negative pressure in the working area. This ensures that during the weighing and sampling process, especially for powders, no dust is released, protecting operators from harmful effects of airborne particles.

Furthermore, the laminar flow and airflow generated from the HEPA Filter ensure that the environment inside the booth maintains the necessary cleanliness levels.

Key Highlights of Sampling Booth provided by VCR

VCR currently offers Sampling Booth from LENGE, a leading cleanroom equipment manufacturer in China, with the following key features:

- Cross-contamination control through negative pressure environment, preventing air from escaping and external contamination from entering the working area.

- Vertical laminar airflow within the working area, creating an efficient and optimized controlled environment.

- Modern air curtains replacing traditional PVC curtains, facilitating ease of work and reducing cleaning efforts.

- Equipped with a PLC programming controller and LCD screen, allowing for easy operation parameter settings, user access control, monitoring, data storage, retrieval, and operational alerts.

- Constructed with durable and seamless Inox 304 frames, with rounded corners for easy cleaning.

- The filtration system consists of three layers: HEPA, Mid Filter, and Pre Filter with a high-quality Gel Seal, ensuring superior sealing performance compared to conventional gaskets.

- Customizable dimensions to meet customer requirements.

- Equipped with accessories from reputable brands such as SIEMENS, SCHNEIDER, and ROSEN.

- All designs are protected by LENGE patents.

- Certified with CE quality standards (European).

- Fully compliant with GMP standards, accompanied by required documentation.

To purchase LAF weighing and sampling equipment, please contact VCR via the following hotlines:

- 090.123.9008 (Call/SMS/Zalo)

- 090.123.7008 (Call/SMS/Zalo)

- 090.444.7008 (Call/SMS/Zalo)

- Email: [email protected]

Alternatively, you can chat directly on the website: vietnamcleanroom.com