3 Factors Affecting The Efficiency Of Fan Filter Unit HEPA Filter

A filter with high efficiency will boost fan filter unit performance. This article will discover 3 factors that affect the efficiency of fan filter unit air filters. These are air resistance, air velocity, and filter area

Air filter, especially HEPA filter has long been the most critical component of fan filter units. Therefore, filter maintenance is indispensable. A filter with high efficiency will boost fan filter unit performance. This article will discover 3 factors that affect the efficiency of fan filter unit air filter. These are air resistance, air velocity and filter area

1. Air resistance

The air flows through the filter, which slows down the air to a certain degree and produces a small resistance.

Resistance refers to the pressure drop across the filter at a given velocity.

The more dense and tightly-knit air filters are, the harder airflow goes through your filter, creating a larger resistance. That being said, these filters are more effective at removing airborne particles and dirt from clean room.

The filter generates a certain resistance under a certain velocity and becomes the air resistance of the fan filter unit.

When the filter reaches a certain resistance value (final pressure drop), the filter should be replaced to ensure good filtration efficiency and performance.

The dirtier the filter, the greater the resistance, and the smaller the air volume at the same air velocity. When the filtration resistance does not increase, it is considered that the filtration device has recovered its filtration function, but actually, the filtration efficiency at this time is zero. Therefore, the filter is a consumable product.

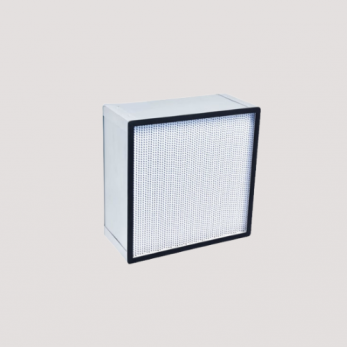

2. Air velocity

In most cases, the lower the air velocity, the higher the filtration efficiency.

Because at low velocity, the diffusion effect of small dust is obvious. The airflow stays in the filter material for a longer time, and the dust has more chances to hit obstacles. The one-time filtering effect is obvious.

For a HEPA filter, if the air velocity is reduced by half, the probability of dust passing through the filter material decreases, and the efficiency increases by 9 (according to MERV Ratings). If the air velocity is doubled, the probability of dust passing through the filter material will be doubled, and the efficiency will be reduced by an order of magnitude (a decrease of 9).

When the air velocity is low, the probability of large particles colliding with the filter during inertial motion is reduced, but this effect is not obvious in practical applications, because the air velocity is reduced, and the rebound force of the filter on the dust is also reduced. Dust adheres more easily, and the filtering effect is significantly improved. Therefore, in practical applications, try to set reasonable low air velocity filter parameters. It has great benefits to filtration efficiency and performance.

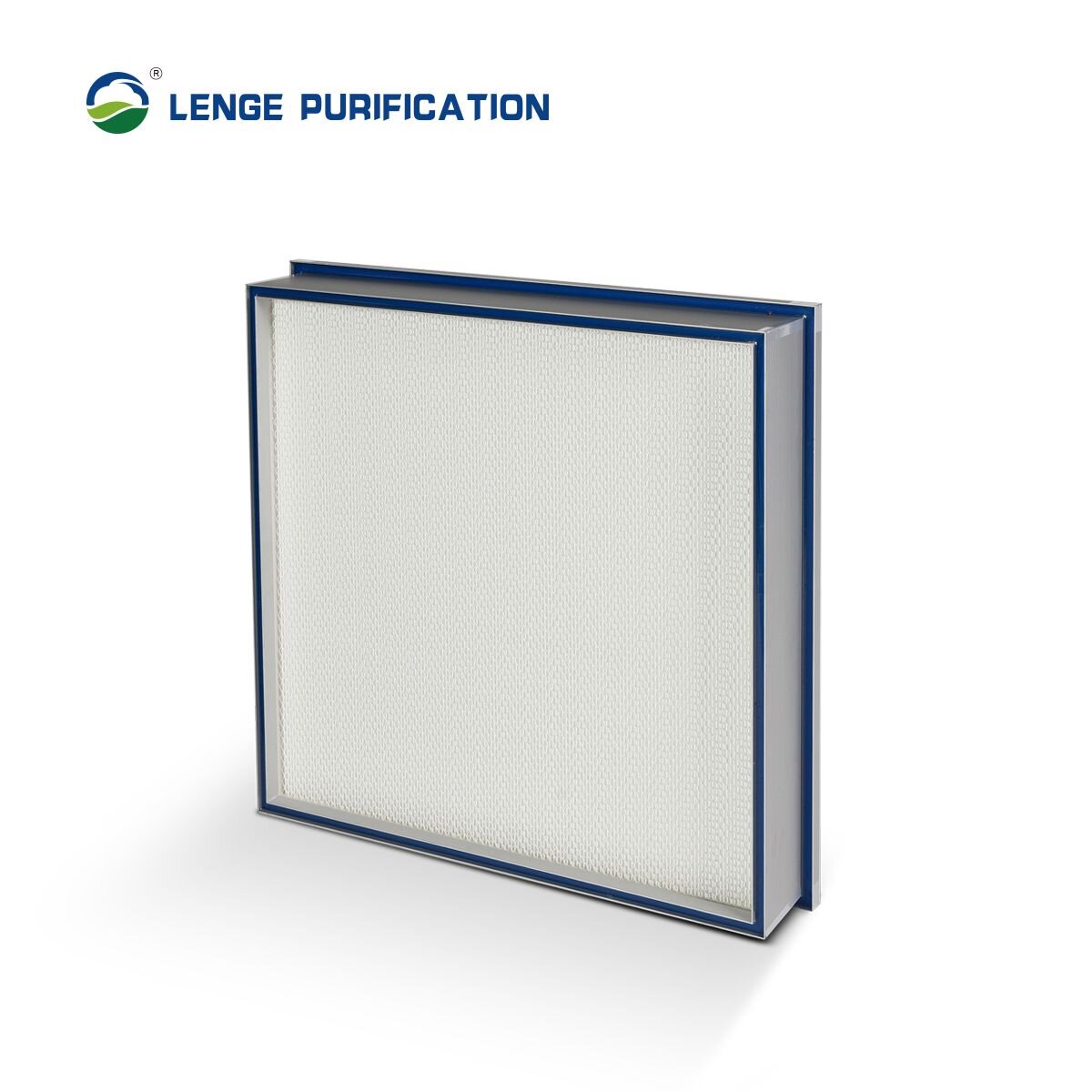

3. Filter area

The resistance of the filter device increases with the increase of airflow and velocity. The trapped or adhered dust increases the resistance to the airflow, which increases the air resistance of the fan filter unit.

On the other hand, the trapped dust filter adheres to one body, the formation of a new filter barrier is a slight improvement in filter efficiency. But the overall filtering effect depends on the size of the filter area. Therefore, the life of the HEPA filter is related to the filter area.

Vietnam Cleanroom Equipment (VCR) specializes in providing cleanroom equipment for construction contractors. We provide high-quality products with competitive prices and large quantities nationwide. The equipment includes:

Differential pressure gauge, FFU Fan Filter Unit, Pass box, Clean room air filter, HEPA box, Clean booth, cleanroom steel door, Isolator cabinet, and other equipment

For details, please refer to Vietnam cleanroom equipment official website