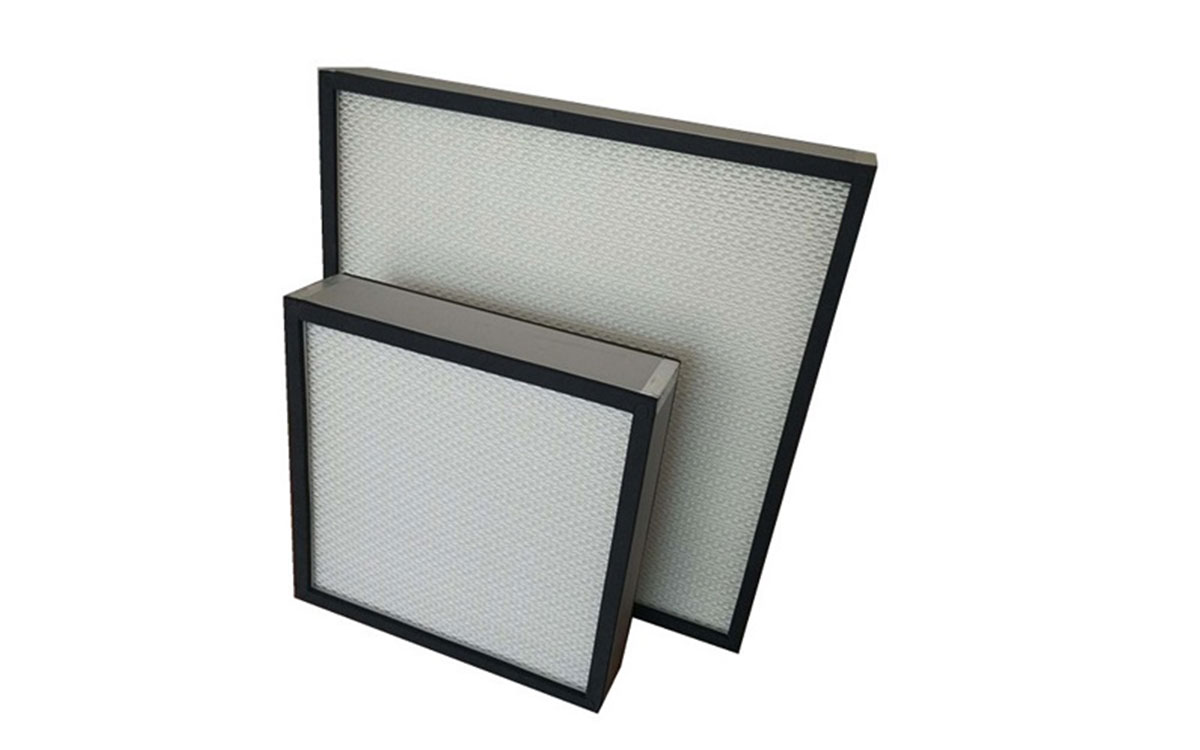

HEPA H13 Filter

HEPA H13 filter is a type of filter commonly used in clean rooms due to its high filtration efficiency. It is capable of filtering tiny dust particles, creating a safe and clean air environment that meets standard requirements.

What is a HEPA H13 filter?

Structure and technical information of the HEPA H13 Filter

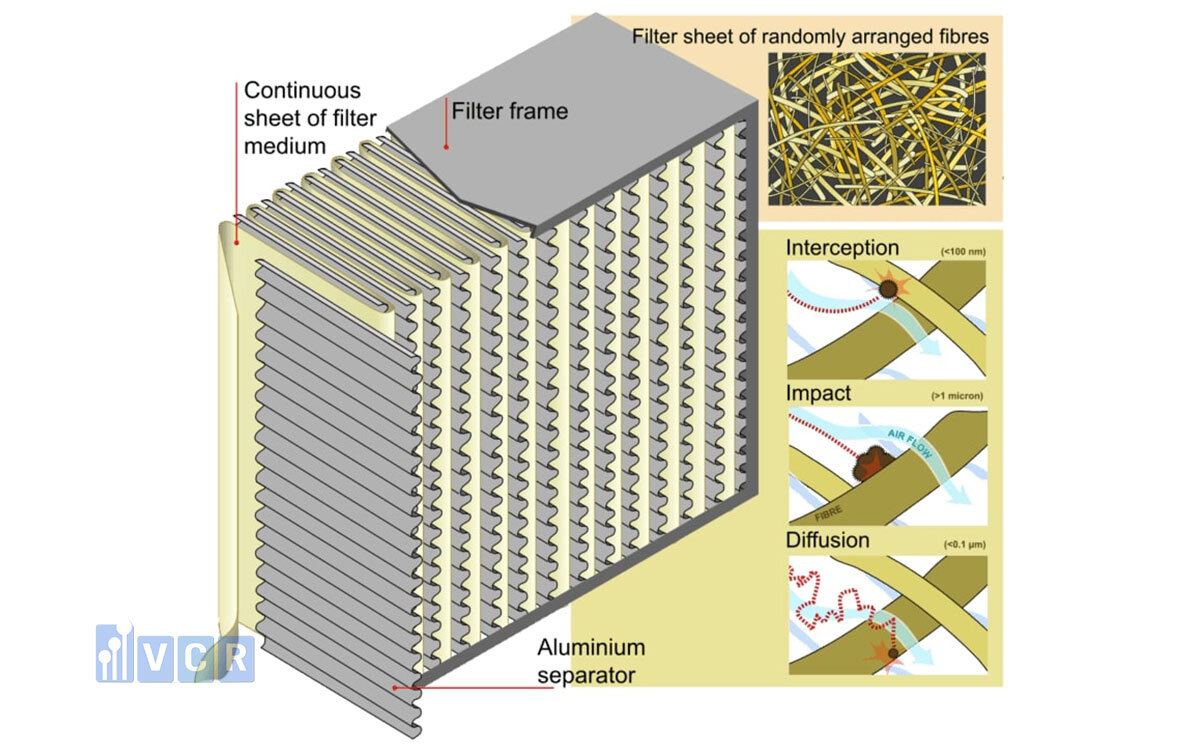

Strucutre

- The filter membrane, made of high-quality fiberglass material.

- The frame, which can be made of either aluminum or wood, depending on customer requirements.

Technical information

- 99.97% filtration efficiency according to EN1822 standard

- Refined filtration in cleanrooms with a level of 0.3micron

- Specialized glue to glue the surface of the exhaust gas

- Filter material: Glass fiber/synthetic fiber

- Initial pressure difference: 250pa

- Final pressure difference: 550 pa

- Common size (mm) : 305 x 305 x 150, 305 x 610 x 150... and produce according to customer requirements

- Standard flow rate (M3/H): 270 - 2880

- High flow rate (M3/H): 450 - 4500

Outstanding Filtration Features of the HEPA H13 Filter Membrane

- This filter possesses the ability to remove up to 99.99% of dust, targeting tiny, ultrafine, and microscopic particles in the air.

- When used with an air purifier, the filter membrane cycles air through multiple stages, releasing it only when fully purified and free of dust particles.

- The filter membrane is exceptionally tough and durable, with a service life that far surpasses other filter products.

- The HEPA H13 filter membrane is highly effective at removing allergens and microorganisms, making it ideal for sensitive environments. It significantly reduces harmful biological agents in spaces with high air-quality standards.

- Though the product may be more costly than other filters, it is well worth the investment, providing an exceptional filtration solution.

HEPA H13 Filter Classification

HEPA H13 filter membrane is usually divided into 2 main types:

Separator Type HEPA Filter

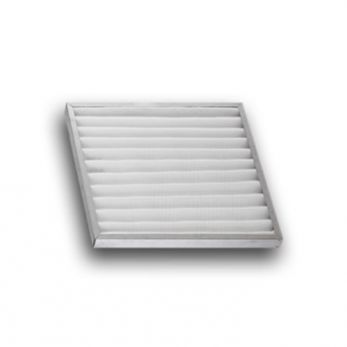

HEPA H13 Mini Pleat Filter

Uses of HEPA H13 filter membrane

- Cleanroom Air Filter: Meets the Class 100,000 standard and is suitable for use in AHU systems and hospital operating rooms.

- Allergen and Germ Control: Effectively traps allergens and germs, protecting sensitive production equipment and weighing devices from harmful biological agents.

- Dust Filtration: Can capture small dust particles that may cause allergy or asthma symptoms, making it suitable for air purifiers and microbial incubators.

- Installation in Air Handling Units: Commonly installed at AHU centers or along return air ducts. It is also used for air vent filters at false ceiling heights.

- Controlled Airflow Environments: Suitable for locations where airflow speed control is required, such as at 0.45 m/s, and for use in laminar flow systems.

- Centralized Technical Boxes: Often centrally installed in technical boxes to distribute airflow across multiple rooms; also used in AirShowers and Clean Benches.

- High-Traffic Spaces: Ideal for crowded areas with high air quality demands, including shopping centers, hotels, and restaurants.

Notes for using HEPA H13 Filters

- Carefully read the installation instructions to avoid improper installation, which may affect the filter's performance.

- Clean the filter membrane regularly to improve filtration efficiency and extend its lifespan.

- Avoid strong impacts, as these can damage the mesh or frame, significantly affecting the product's filtration quality.

With its exceptional features, the HEPA H13 filter membrane is a highly effective and optimal filtration solution for your needs.

Properly Clean the HEPA H13 Filter Membrane

4 steps to clean the HEPA H13 filter

Notes for Cleaning the HEPA H13 Filter Membrane

- Avoid using cleaning chemicals, as they may damage the filter membrane.

- Clean the filter every 2-3 months for optimal performance.

- Do not apply excessive force during cleaning, as this could tear or alter the structure of the HEPA H13 filter membrane.