What is a Cartridge Filter Core? Structure and Operating Principle

The cartridge filter core, commonly referred to as the dust filter core, cartridge filter tube, or cartridge filter, is designed to remove dirt and impurities from liquids and air. It is a versatile filtration solution used across various industries for both air and liquid purification.

What is a Cartridge Filter Core?

Structure of Cartridge Filter Core

- Internal filter core: Made from natural or synthetic fibers, supported by a wire mesh frame in the center.

- Outer shell: A mesh structure that provides protection for the inner filter core.

Read more:

Operating Principle of Cartridge Filter Core

Specification of cartridge dust filter

|

Figure

|

Round pillar

|

| Outer diameter | 120-320 mm |

| Inner diameter | 85-230 mm |

| Height | 500 - 1500 mm |

| Filter material | PE fiber, PTFE fiber,... |

| Temperature | 200-890℃ |

| Guard-net | Steel, stainless steel (inox) |

Some Popular Cartridge Dust Filters

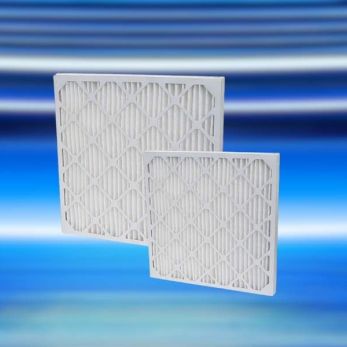

Air Filter Cartridges

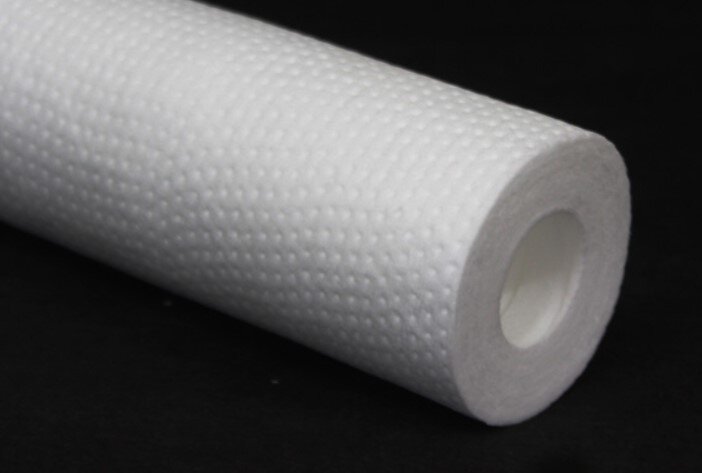

Liquid Filter Cartridge Core

- Material: natural or synthetic fibers, wound around a central support frame

- Filters: sand, sediment, lime, rust, fine dust particles, and dust particles ranging from 0.5 to 150 microns in size

- Applications: drinking water, boilers, washing machines, water treatment filtration, seawater desalination, and more

- Length: 127mm, 254mm, 508mm, 762mm, 1016mm

- Material: made from polymer fibers that are pressed and fixed thermal bonding, then blown to melt into the rotating axis to create a cylindrical filter

- Filter: sand, sediment, lime, rust, fine dust particles with a size of 1-75 microns

- Application: Melting cartridge filtration is widely used in sedimentation applications, water treatment, preliminary filtration of pure water, refined chemicals, reverse osmosis, seawater desalination, beverages, solvents, cosmetics ...

- Length: 127-254-508-762-1016 mm

- Material: made from wool fibers, or washed polypropylene fibers or polyester felt filter media, bonded with activated carbon particles

- Remove color, odor, taste, pesticide, chlorine pollution, organic matter

- Filter dust particles, pollutants with a size of 1-25 microns

- Application: Drinking water, washing machine, anti-chlorine treatment in the chemical industry, pharmaceuticals, treatment for reverse osmosis units…

- Length: 101-127-177-254-508-762 mm

- Material: stainless steel filter mesh with an inner core made of polypropylene fiber.

- Filter: sand, sediment, rust with a size of 70 microns

- Application: drinking water filtration, washing machines, boilers, preliminary filtration for pumps, irrigation systems, industrial system protection ...

- Length: 101-127-177-254-508 mm

- Material: Polypropylene or stainless steel filter mesh with many folds with a polypropylene inner core.

- Filter: Sand, sediment, rust with a size of 50 microns

- Application: Drinking water, boilers, washing machines, pre-filtration of water, pumps, irrigation systems, protection of industrial works ...

- Length: 101-127-177-254-508 mm

- Material: The core is made of polypropylene fiber, the outer shell is made of oil mass absorbing material

- Remove: oil, dispersant and emulsifier

- Application: oil and gas industry, transformer wastewater treatment system, surface water, other industrial applications ...

- Length: 1016 mm

Application of Cartridge Dust Filter Core