HEPA filter classification: Separator HEPA filter and mini pleat HEPA filter

HEPA filter is becoming more and more popular in industrial applications and household appliances. How many types of HEPA filters? In this article, VCR - Vietnam Cleanroom Equipment will address HEPA filter classification. Let's get into it! 1. HEPA

HEPA filter is becoming more and more popular in industrial applications and household appliances. How many types of HEPA filters? In this article, VCR - Vietnam Cleanroom Equipment will address HEPA filter classification. Let's get into it!

1. HEPA filter

HEPA filter or High-Efficiency Particulate Air filter is the technology designed in 1940 to capture radioactive contaminants. In general, HEPA filter is comprised of interlaced glass fibers that are twisted and turned in countless directions to create a fibrous maze. Therefore, HEPA filter media could capture small particles that are the most common trigger of respiratory and asthma symptoms, such as pollen, fungal spores, smoke, fur, etc.

Basically, there are 4 layers of HEPA filter: first filer, synthetic material filter, carbon filter, and HEPA filter. Each layer has different use.

Read more: What is HEPA filter?

2. HEPA filter classification

Currently, HEPA filters are categorized into 2 types: Separator HEPA filter and mini pleat HEPA filter.

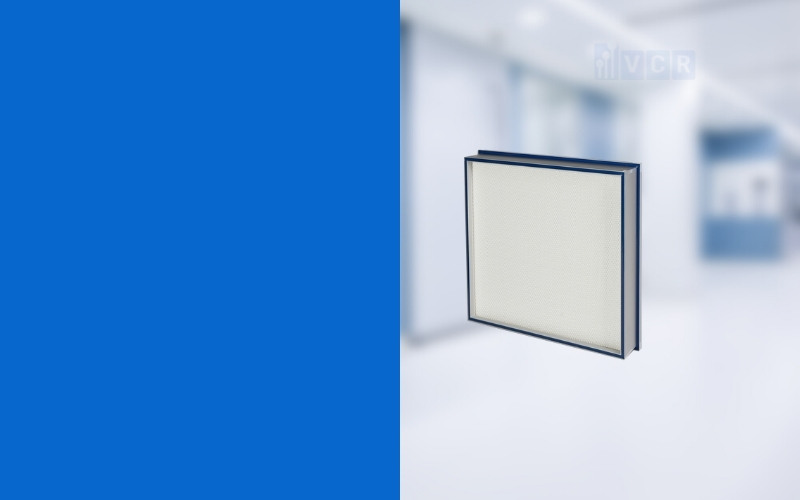

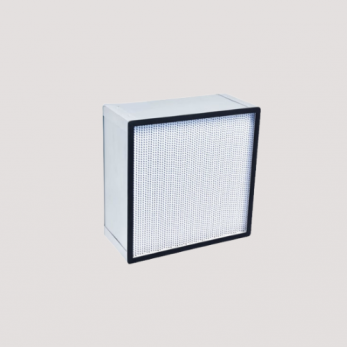

Separator HEPA filter

Separator HEPA filter has the thickness of 150 mm - 292 mm.

Separator HEPA filters with a thickness of 150 mm are suitable for vent-mounted filter designs with a ceiling height of about 450 mm.

Separator HEPA filters with a thickness of 292 mm are suitable for installation in AHU or air exhaust, ceiling height of about 600 mm and installation at the vent.

Separator HEPA filters has high air velocity. When installing in manufacturing areas, the air velocity should be decreased. If the air velocity through HEPA filter is too high, it is counterproductive. This could lead to dust accumulation, which pose a risk to manufacturing environment.

Separator HEPA filter is more expensive than other types of filter.

Separator HEPA filter usually made of fiber glass which separated with paper or aluminum foil. Frame of separator HEPA filter can be made of aluminum alloy, steel or stainless steel.

Mini pleat HEPA filter

Mini pleat HEPA filter is thinner than separator HEPA filter. Mini pleat HEPA filter has the thickness of 60 mm - 100 mm and diffferential pressure of around 80 - 160 pa. HEPA mini pleat filter has 2 protective nets, which prevent the filter from damage.

Mini pleat HEPA filter is applied in an environment where the air velocity is about 0.45 m/s and applied to lamilar flow. The mini pleat HEPA filter is rather thin and has a very low pressure drop because of its very long life.

Mini pleat HEPA filter usually made of fiber glass which separated with hot-melt adhesive. Frame of separator HEPA filter can be made of aluminum.

3. HEPA filter application

HEPA filter removes 99.95% of dust, pollen, mold, bacteria, and any airborne particles sized 0.3 microns or larger (µm), so it is applied in many different fields, especially in the construction of clean rooms, such as hospitals, etc.

In addition, HEPA filters can also be installed on cars, laboratories, shipping ships, places where fresh food and medical equipment need to be preserved, etc. HEPA filters are also used to filter pollen, fungal spores and smoke. According to research, HEPA filters can remove 99.99% of pollen, animal hair and even harmful bacteria.

Besides the above benefits, HEPA filters are also used on airplanes. It can reduce the spread of airborne pathogens, eliminating worries about the efficiency and maintenance of the air filtration system. Air in an airplane is drawn from outside, circulates in the cabin, and exits through exhaust valves in the rear of the airplane.

Read more: HEPA filter replacement