Understanding Cleanroom Filtration: A Guide to HEPA

Are you hip to HEPA? When it comes to cleanroom filtration, HEPA is at the top of the heap. Controlling contamination in your cleanroom depends on a reliable air filter system. HEPA is your helper in removing air impurities. Read on to learn more about

Are you hip to HEPA? When it comes to cleanroom filtration, HEPA is at the top of the heap. Controlling contamination in your cleanroom depends on a reliable air filter system. HEPA is your helper in removing air impurities.

Read on to learn more about the benefits of using and testing HEPA filters to maintain your cleanroom’s pristine environment.

But, first…

What Is a Cleanroom?

Cleanrooms are tightly controlled environments commonly built in order to manufacture:

+ Sensitive electronic components for the aerospace and automotive industries

+ Pharmaceuticals

+ Certain foods

+ Certain healthcare products

Without adequate air filtration control, contamination can spell disaster for processes and products. This is why cleanroom HEPA filters are so necessary.

Cleanrooms are designed according to the sensitivity of what will be produced inside the space.

There are different class specifications that speak to the sensitivity level required, in terms of particulate size and dispersion.

Cleanroom Classifications

US Federal Standard 209E (Airborne Particulate Cleanliness Classes in Cleanrooms and Clean Zones) was the prior standard for cleanroom classifications.

After November 2001, guidance from the International Standards Organization (ISO) superseded FS209E as the international standard for cleanroom classifications.

The current effective publication from ISO is 14644 (Clean rooms and associated controlled environments), updated in 2015.

It has 12 parts. The two most important for your cleanroom classification and monitoring are:

+ ISO 14644-1:2015

Part 1: Classification of air cleanliness by particle concentration

+ ISO 14644-2:2015

Part 2: Monitoring to provide evidence of cleanroom performance related to air cleanliness by particle concentration

ISO cleanroom classifications are defined by how much particulate of specific sizes (0.1 micron – 5 micron) exist per cubic meter in the cleanroom space.

Classifications range from ISO 1 (“cleanest”) to ISO 9 (“dirtiest”).

You may still see or hear of FS209E cleanroom classifications. Under that standard, Class 1 is the “cleanest” and Class 100,000 is the “dirtiest”.

Cleanroom Testing Stages

Since particulate levels change as activity in the cleanroom varies, the ISO classification levels are tested at 3 different stages:

1. As built

Classification is easiest to achieve at this stage

Cleanroom installation is complete

All services are connected and functional

No equipment, materials, or personnel are present

2. At rest

Installation complete

Equipment installed and operational as agreed-to

No personnel present

3. Operational

Classification most difficult to achieve at this stage

Installation functioning in a specified manner

Personnel working in space as planned

People are the largest contaminant in a cleanroom

To determine the classification of your cleanroom, you must first define your process, your end product, and the sensitivity required for particulate size and level.

Cleanroom Filtration System

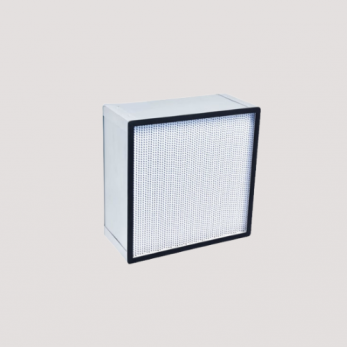

The air filtration system is the most important component of a cleanroom. The filters are designed to remove the particulates in the air down to sub-micron sizes.

The standard High-Efficiency Particulate Air (HEPA) filter will scrub air down to 0.3 microns at an efficiency of 99.975%.

There are other filters in use (EPA and ULPA), but HEPA is the most universally employed and our focus here.

A HEPA filter is produced with many pleated layers of filter media paper.

The purpose is to prevent particles from freely passing through the media paper. Instead, they get stuck in the filter fibers.

With such a design, there are several principles being used:

Straining/Sieving – A particle is too big and becomes trapped between two filter fibers

Interception – Occurs when a piece of a particle “collides” with a filter fiber

Impaction – Heavier particles are unable to follow the curved streamline around the fiber and their momentum carries them in a straight line into the filter fiber where they stick

Diffusion – Due to random collisions with surrounding fluid molecules, particles leave the streamline and strike the fibers, where they get stuck

A malfunctioning HEPA filter can permit contaminants to enter a controlled environment.

Filters must remove impurities from the air while avoiding transferring impurities that could land on a device’s or product’s surface.

Testing Your HEPA Filtration System

Testing per the accepted standard (European Norm EN1822:2009) is used to certify filtration performance.

Testing in accordance with EN1822 is normally accomplished with an aerosol probe.

The probe is moved over the entire surface of the filter. This “scanning” with the aerosol probe allows local collection efficiencies to be measured.

These local efficiencies can be used to compute the overall efficiency of the filter or the leak rate of a specific area of the filter.

The leak rate is often referred to as the local value, while the overall efficiency calculation is called the integral value.

We are experts in performing this testing to the required standards. You can count on us to get all the testing and validation done precisely and proficiently so that you can maintain your cleanroom properly.

HEPA Filter Lifespan

As as the case with all filters in all applications, the life expectancy of a cleanroom HEPA filter depends on the specific operating conditions of your cleanroom’s HVAC system.

Factors that may influence filter service life include:

The volume of outside air filtered

The volume of recirculated air filtered

Aerosol challenge exposure frequency and duration

The efficiency of the pre-filtration method(s) used

Repairing or replacing HEPA filters can be expensive.

This is especially true if they were custom-made for your specific situation. Delivery time for replacement parts must be taken into account when planning maintenance.

Adherence to good preventive maintenance practices will help keep filters working right.

This will help minimize premature replacement, with the associated costs for parts and labor as well as disruption to your operations and potential contamination.