3 reasons for unqualified cleanliness in GMP cleanrooms

Getting GMP certification is not an easy task. This article will list 3 main reasons for unqualified cleanliness in GMP cleanrooms. Let's find out! When the GMP cleanroom is tested, there are often some cases where the cleanliness test fails. It could be

Getting GMP certification is not an easy task. This article will list 3 main reasons for unqualified cleanliness in GMP cleanrooms. Let's find out!

When the GMP cleanroom is tested, there are often some cases where the cleanliness test fails. It could be the failure of a part of the cleanroom, or the whole project fails.

Most engineering causes and defects are completely avoidable before cleanroom design, construction, and testing.

3 reasons for GMP cleanroom unqualification are shown below:

1. Unreasonable cleanroom design

In fact, this situation is relatively rare. If there is, it generally occurs in the construction of small cleanrooms with low cleanliness level requirements.

Now the competition for purification is fierce. In order to obtain the project, some constructors use a number of companies to surround the bid and give a lower price in the bidding to obtain the project.

In the construction process, taking advantage of the fact that some units are not very knowledgeable, they replace and purchase low-cost and inferior materials without permission (Party A usually cannot see it), cut corners, and use OEM or low-power air-conditioning ventilation units (to make project profits). The air supply power does not match the clean area, resulting in unqualified cleanliness, which is often done by small and medium-sized engineering companies in the entire industry.

Another reason is that after the start of design and construction, the user has added new requirements and purification areas, which will make the original purification engineering design unable to meet the requirements. Such defects are difficult to improve and should be avoided in the engineering design stage.

Some constructors pre-block some of the air supply openings in order to pass the inspection. From this point alone, the first party who saw this article, will not let their cleanrooms be done by engineering companies that believe in those low-price promises, rhetorical copywriting, and no professional design team!

2. Cleanroom equipment is substituted with inferior equipment

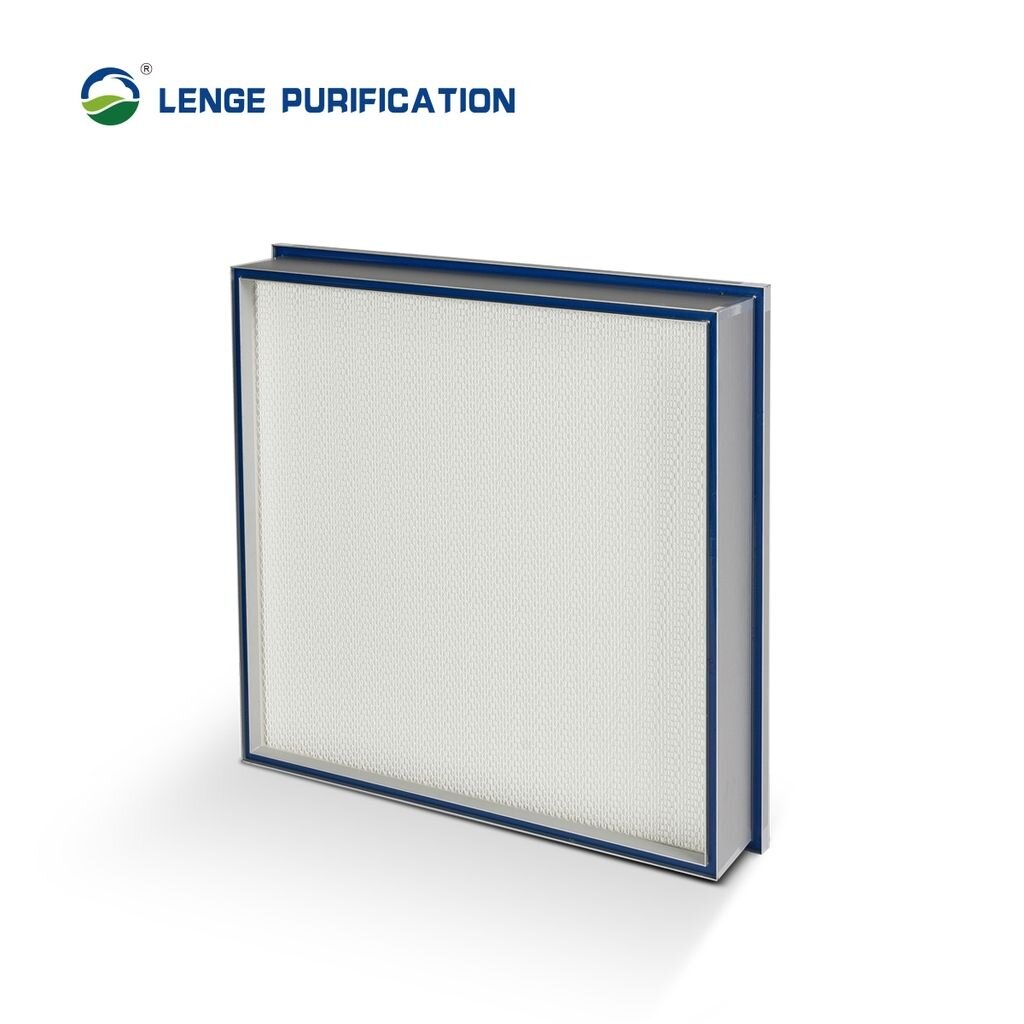

According to the cleanroom standards, in the air purification treatment with a cleanliness level of 100,000 or higher than 100,000, pre-filter, medium filter, and high-efficiency filters should be used.

During the verification process, a large-scale cleanroom project used sub-high-efficiency air filters instead of high-efficiency air filters at class 10,000, resulting in unqualified cleanliness of the GMP cleanroom. Only after replacing the high-efficiency filter (HEPA filter), can it meet the requirements of GMP certification.

3. The air supply pipe or filter is not well sealed

This situation is often caused by rough construction, and it generally shows that a room or part of the same system is unqualified during acceptance.

The solution is that the air supply pipe adopts the light leakage test method to detect leakage, and the filter uses a particle counter to scan the section, sealing glue and installation frame of the filter to find out the leakage position and carefully seal it.

According to regulations, the test is usually started after the air handling system has been running normally for 30 minutes. Because the running time is too short, it will also cause unqualified cleanliness.

Vietnam Cleanroom Equipment (VCR) specializes in providing cleanroom equipment for construction contractors. We provide high-quality products with competitive prices and large quantities nationwide. The equipment includes:

Differential pressure gauge, FFU Fan Filter Unit, Pass box, Clean room air filter, HEPA box, Clean booth, cleanroom steel door, Isolator cabinet, and other equipment

For details, please refer to Vietnam cleanroom equipment official website

https://en.vietnamcleanroom.com