8 Things You Should Pay Attention To When Transporting HEPA Filters

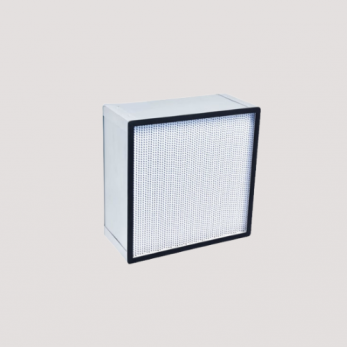

HEPA filters are usually installed at the end of the cleanroom. Due to high filtration efficiency, low flow resistance and long-term use, HEPA filters require strict design and production process. Transporting filters also need to follow certain standards.

HEPA filters are usually installed at the end of the cleanroom. Due to high filtration efficiency, low flow resistance and long-term use, HEPA filters require strict design and production process. Transporting filters also need to follow certain standards. Here are 8 things to pay attention to when transporting HEPA filters.

1. Careful transportation

The transportation of HEPA filters should be carried out in an upright manner. Avoid external factors, rain. The handling process should be cautious.

2. Height caution when arranging HEPA filters

The stacking height of the filters during transportation should not exceed two meters, and other items are not allowed to press on the HEPA box.

3. Fixed position

The filter should be fixed to prevent the filter elements from being damaged due to the shaking of the filter during transportation.

4. Upright arrangement during transportation

Storage should be kept upright in the original box, stacked according to the signs on the box, and placed on flat ground or pallet. The stacking height should not exceed two meters.

5. Arrangement during storage

Store HEPA filters in a clean, dust-free room, store upright with the header facing up. Prevent the filter from tipping over.

6. Storage space

HEPA filters must not be stored in humid, cold, hot or temperature-changing places, and it is strictly forbidden to stack them in the open air.

7. Temperature and humidity

The recommended storage temperature is 0℃ < T < 40℃ and the relative humidity is less than 60%.

8. Storage time

The storage time of HEPA filter should not be too long, otherwise, it will affect the filter. For ordinary filters, the recommended maximum storage period is 1 year. For filters equipped with gel, the recommended maximum storage period is 2 months.

Read more about air filter here