BIBO Bag In Bag Out system and its working principle

BIBO system or Bag In Bag Out system is a device designed to change the filter with the purpose of protecting the environment, ensuring the safety of the operator. This device is commonly used in cleanrooms where personnel work with hazardous biological,

BIBO system or Bag In Bag Out system is a device designed to change the filter with the purpose of protecting the environment, ensuring the safety of the operator. This device is commonly used in cleanrooms where personnel work with hazardous biological, radiational, and carcinogenic components.

BIBO can remove harmful substances in the air, biological, radioactive, pollutants contained in the filter of the BIBO box through the system until the filter is changed and incinerated.

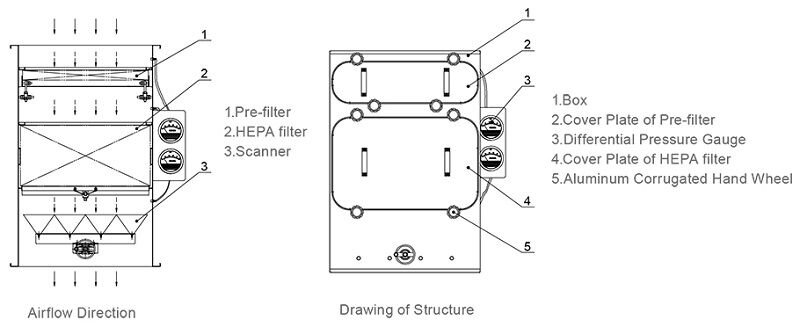

BIBO System Structure

Body

The air inlet and outlet ports of the body are connected to the pipelines through closing valves, bio-sealed valves are provided according to customer requirements.

The body of BIBO system is manufactured by laser cutting and numerically controlled bending to ensure accuracy during the production process. The body is also welded continuously and seamlessly by an automatic welding robot.

The surface of the casing should be sprayed with carbon steel epoxy resin and the coating is resistant to corrosion by disinfectants such as formaldehyde and hydrogen peroxide (VHP). In addition, the material for the body can be carbon steel and SUS304 stainless steel.

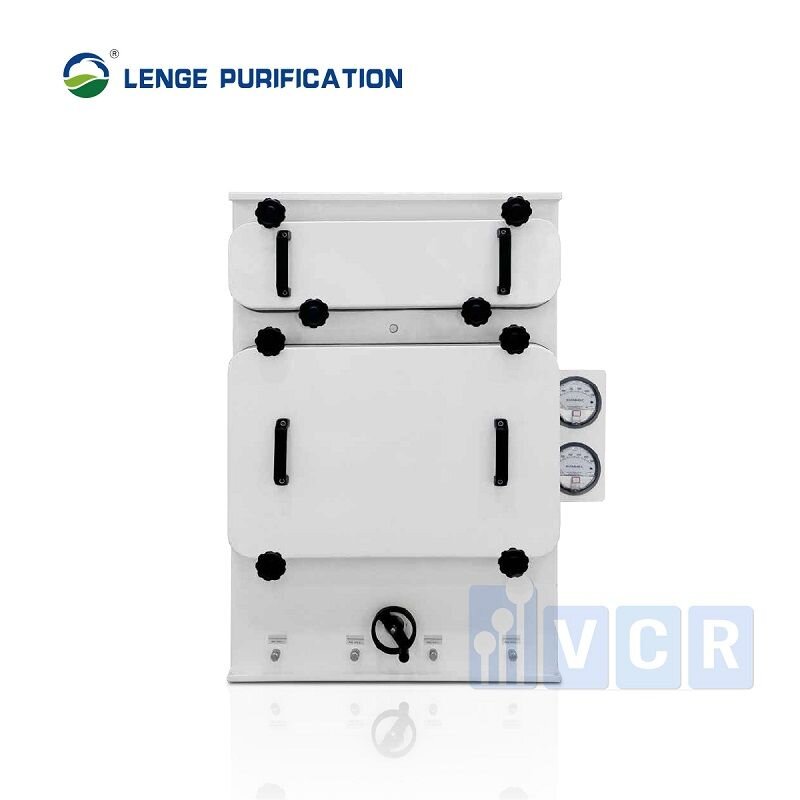

Image: BIBO body

Biological sealing valve (optional)

Bio-sealed valves are used in highly hazardous discharge systems to isolate the filter from the surrounding environment.

The bubble-tight valve is the most advanced in the air valve product line, used for isolation during filter replacement, especially effective isolation for high volume air systems.

Valves are usually circular in shape and can be equipped with electric and pneumatic actuators.

The vanes are tested to the off position and to a 10-inch head of water, meeting the standard requirements. The valve must also be tested for overall pressure according to the relevant standards.

Air filter

The efficiency level of the HEPA filter in BIBO system is H14, and the filtration efficiency is 99.995%@MPPS. The outer frame is made of zinc-aluminum or stainless steel SUS430 / SUS 304. The sealing HEPA filter method is to use a gasket or silica gel.

In BIBO system, it is possible to use a single-stage filter (H13 or H14), a multi-stage filter (G4 + H13 or M6 + H14), or a multi-stage filter in the exhaust system (G4 + F8 + H14 + H14);

The maximum airflow of a single BIBO filter module can reach 4000CMH.

Image: BIBO system structure

PVC bag

PVC bags are used to prevent replacement and maintenance personnel from coming into contact with the filter when replacing filter. PVC bags have the characteristics of high strength and are not easily broken.

Patented special design-shaped rubber ring, good locking effect on PVC bags.

Differential pressure gauge

Each filtration stage or each filter in the BIBO should be equipped with differential pressure gauges. To check the pressure of the filter, it needs to be equipped with differential pressure gauges, tool racks, connectors, connecting pipes, etc. A differential pressure transmitter to transmit the signal to the central control system should be added, if necessary.

The pressure gauge pipeline in the pressure detection structure is equipped with an airtight isolating valve, the upstream and downstream lines of the pressure gauge are equipped with a highly efficient filter and sterilization port, which can sterilize inside upstream and downstream pipelines.

Pressure gauge pipe and related accessories are stainless steel SUS 304.

On-site disinfection area

The upstream and downstream locations of the filter are equipped with gas sterilization interfaces, which can be connected to internationally accepted standard sterilization equipment.

The bag is equipped with stainless steel ball valves inside and outside the bag, which can be easily injected with air disinfectant to make the air spread evenly over the surface of the filter and sterilize any parts.

It is possible to check whether the concentration of the sterilized air meets the requirements of the sterilization specification. It can be done by detecting the sampling port at the top of the filter and checking the sterilization efficiency through the disinfection verification port at the bottom.

Leak detector

Before being marketed, HEPA filters have undergone rigorous leak detection and filtration efficiency tests to ensure that their filtration efficiency meets customer requirements (H13 or H14). The middle diameter of the aerosol detector is 0.3um, and the concentration distribution and particle size of the aerosol are uniform and stable. DEHS, PAO (Test DOP), and other substances can be used to perform the test.

When it comes to each level of high-performance filter, a manual or automatic scanning system can be selected for leak detection. The scanning device performs an effective test on the filter in working conditions to detect whether the filter is leaking. GB19489-2008 Standard should be followed for leak detection.

Fan

Fans need to be designed according to customer requirements and provide variable frequency motor control to achieve energy-saving purposes.

The principle of operation of BIBO - Bag In Bag Out

The filter is replaced in a protective bag, which can prevent the air in the box from coming into contact with the outside, thus protecting the safety of the operator and the environment. The protective bag is equipped with gloves to make it easier for staff to replace.

When using BIBO to replace the filter, the equipment being replaced must be turned off and the airflow is inoperative. The operator wears protective equipment and removes the filter through the gloves on the bag. The bag is wrapped and sealed for airtightness, then the old filter is separated and disposed of properly. Place the new filter in the bag, secure the bag on the BIBO door, put the new filter on the BIBO through gloves, remove the old bag, remove it after the package is sealed, and dispose of it properly. The new filter is fixed, and the bag is neatly folded so that it can be replaced next time.

During filter replacement, the filter is not exposed to people and the outside environment, so it becomes a bag-in-pocket replacement method. This can prevent contaminated filters from contaminating the environment and harming employees.

It is essential to use BIBO as a filter replacement for applications that work with hazardous environments. Understanding the structure and operating principle of BIBO will help us better understand this device, so that filter replacement is done more properly.

See more: BIBO - Bag In Bag Out Application