HEPA Filter In Fan Filter Unit Leak Test

The HEPA filter leakage testing process involves releasing particles and checking concentration, checking the filter and frame to detect leaks, replace or repair and re-test. Let's find out with VCR - fan filter unit supplier in Viet Nam

I. HEPA filter in FFU

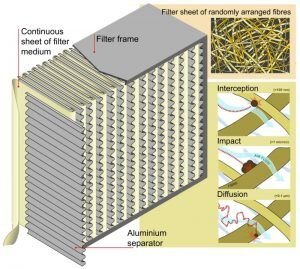

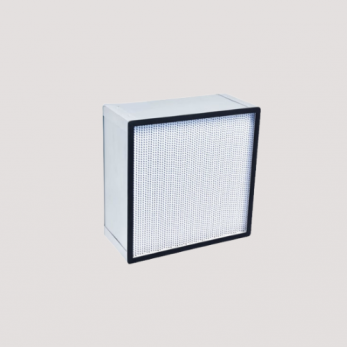

1. HEPA filter structure

- Filter material: H13, H14 filter paper, and U15-U17 HV fiberglass air filter paper

- Sealant: Urethane rubber liquid, hot melt adhesives

- Frame: Aluminum frame, aluminum folding frame, nickel bar, stainless steel bar, plastic bar

- Separator: Hot melt adhesives

- Net: Honeycomb

Hepa filter structure

2. Hepa filter efficiency

- H13: 99,99% @ 0,3 µm to U17: 99,999995% @ 0.12µm.

- The price of the filter depends on different filter efficiency. The higher efficiency, the higher price.

- Operating temperature: ≤ 70℃

- Humidity: 100℃

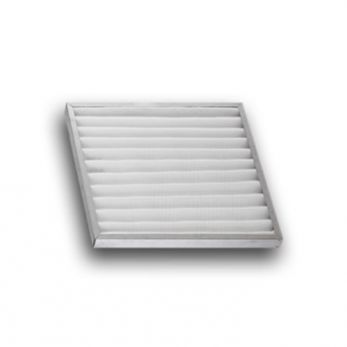

3. Frame

Customized frame thickness ranges from 46mm, 50mm, 69mm, 80mm, 90mnm to 96mm (with external frame: aluminum alloy, laminated frame,...)

H13 Hepa filter

II. HEPA filter leakage testing instruction

The HEPA filter leakage testing process involves releasing particles and checking concentration, checking the filter and frame to detect leaks, replace or repair and re-test. The steps are described below:

- Step 1: Write down the quantity and filter code on technical drawings

- Step 2: You have to make sure the air conditioning system is working properly, whether it can check the air velocity and the airflow rate or not. Next, we have to adjust them to equilibrium.

- Step 3: Using an aerosol generator to release upstream particles and put PAO into the upstream filter net. The particle depth is about 10 -20 micrograms PAO per liter of air. The more particles there are, the easier it is to detect leaks. If the particle depth is over 50 micrograms, the difference is little. If it is below 10, the filter net should not be used. The particle concentration can be estimated to the airflow, and then confirmed with an aerosol photometer.

- Step 4: After testing the concentration of upstream particles, the surface of the sieve can be scanned for leaks. If necessary, a plastic shield around the strainer can be used to ensure accurate measurement results.

- Step 5: Scanning on a high-performance filter surface, the scanner can check the external and internal filter, or along the long/short edge.

Fan filter unit with HEPA filter

Read more about fan filter unit here