HEPA Filters And ULPA Filters Comparison

Table of content 1. Size of particulates trapped 2. How HEPA and ULPA air filter works 3. Which filter is right for you?. What are the differences between HEPA and ULPA filters? Let's find out with VCR - cleanroom equipment supplier in Viet Nam

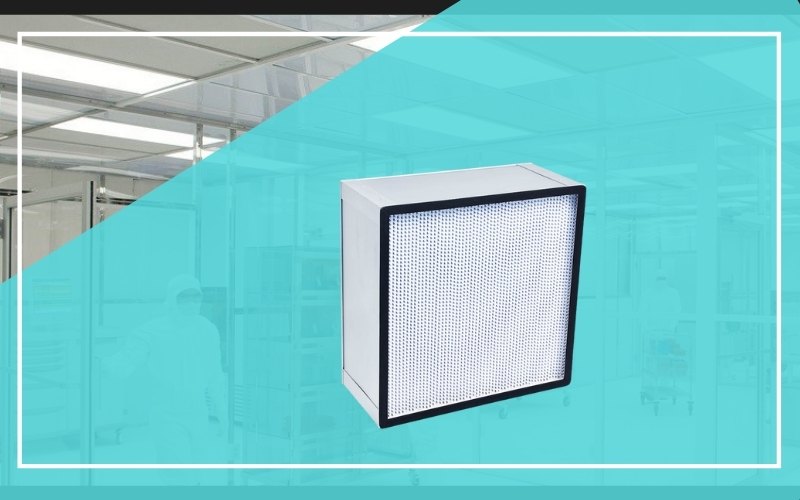

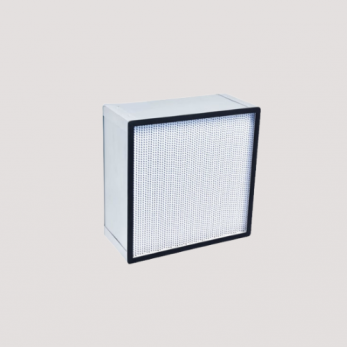

HEPA filter: High-Efficiency Particulate Air filter

ULPA filter: Ultra-Low Particulate Air filter.

HEPA and ULPA air filters keep dust and other contaminants from landing on surfaces in the cleanroom. While similar in many ways, there are some fundamental differences that make choosing the right filter an important decision.

If you work in a cleanroom, you already know the importance of keeping it free of contaminants. Escaped dirt and other particles can lead to big problems down the road including equipment failure and or product contamination.

Let’s learn about the key differences between a HEPA and ULPA filter.

1. Size of Particulates Trapped

HEPA and ULPA filters are categorized by their minimum collection efficiency rating which is ultimately determined by a variety of international standards and classifications.

The following illustrates the difference in collection efficiency between HEPA and ULPA filters:

- HEPA: 99.97% efficiency for the removal of 0.3 µm diameter or larger PM (submicron particulate matter)

- ULPA: 99.9995% efficiency for the removal of 0.12 µm diameter or larger PM (submicron particulate matter)

Both filters are ideal for trapping and removing submicron particulate matter, but ULPA filters have a slight edge over HEPA filters in terms of being able to trap smaller particles.

This may not seem like much of a difference, but for the needs of clean rooms, it’s a big difference. Filters use three main ways of trapping particles: interception, inertial impaction, and diffusion. Larger particles of 0.4 microns or larger are easily trapped by both filters via inertial impaction.

Particles smaller than 0.1 microns are trapped via diffusion, but it’s difficult to effectively trap particles between these two sizes and this is where efficiency drops for HEPA filters. Particles between those sizes are too big for diffusion entrapment and smaller than those affected by inertial impaction.

Scientists designed ULPA filters to trap particles in this range specifically and thus have a higher efficiency rating overall than HEPA filters.

2. How HEPA and ULPA Air Filters Work

Air duct heating and cooling systems naturally collect dust and debris. Even with regular cleaning, cleanrooms can’t afford dust escaping onto electronic parts, etc. HEPA and ULPA filters work in a similar fashion as filters used in furnaces and AC units, just much more efficient at trapping contaminants.

High-efficiency particulate air filters and ultra-low particulate air filters use a layering of dense fibers to create a latticework that is able to trap particles, yet allow for airflow through the material. They are often used in cleanrooms to keep electronics safe and keep pathogens such as bacteria from entering.

3. Which Filter is Right for You?

For many clean rooms, a HEPA filter should be enough to handle your needs. They trap the vast majority of particles and can reduce contamination of the electronic parts.

If your cleanroom requires more stringent contamination guidelines, then ULPA filters meet and often exceed those needs. These are often used for biological clean rooms to make sure there is no cross-contamination of pathogens.