Laminar Airflow Control In Fan Filter Unit (FFU)

The air is drawn at the top of FFU, through filter. Then the filtered air is released. Laminar air is formed which flows in a straight, unidirectional path. It ensures the cleanroom kept particle free.

The air is drawn at the top of FFU, through pre-filter and HEPA filter. Then the filtered air is released with a constant speed of 0.45m/s ± 20%. Laminar air is formed which flows in a straight, unidirectional path. It ensures the cleanroom kept particle free.

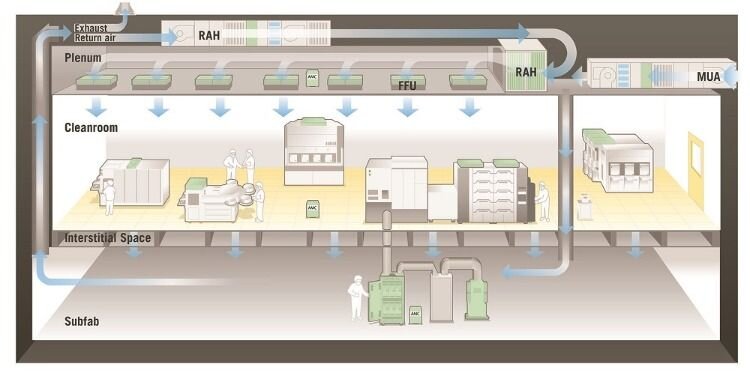

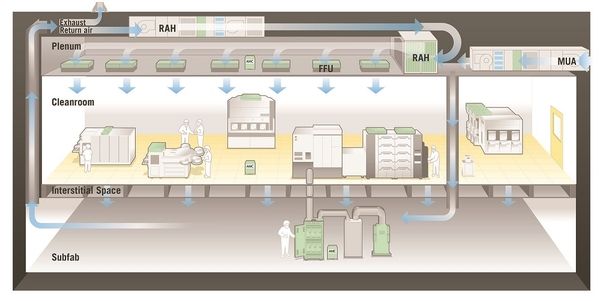

Laminar airflow in cleanroom

Airflow in cleanroom is a key factor affecting the cleanliness of cleanroom. The average air velocity in cleanroom remains between 0.25 and 0.5m/s. It can be easily damaged by human activities. In the case of chaos, increasing the air velocity can suppress the turbulence and maintain cleanliness. But it will increase the operating cost. Therefore, keeping the appropriate air velocity, when the required cleanliness level is met, is necessary for technical and economic efficiency.

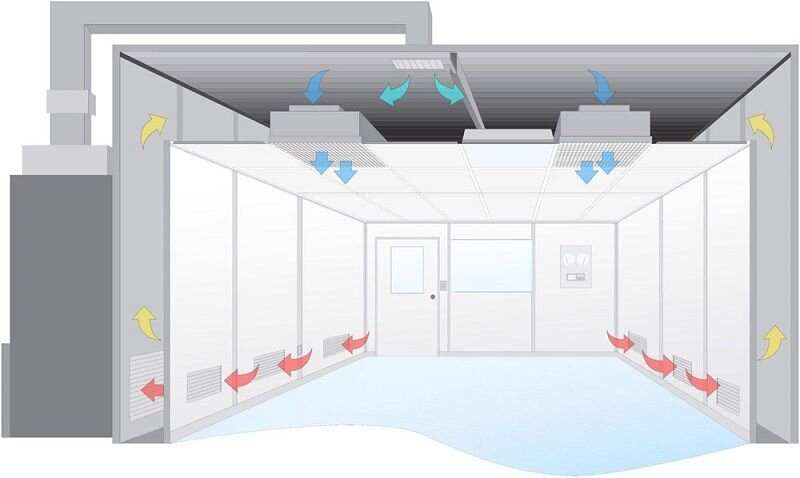

Laminar flow from fan filter unit maintenance

In order to achieve a stable effect of cleanliness in cleanroom, the maintenance of laminar airflow is an important factor. If the laminar airflow cannot be maintained, it means that the flow is not controlled, especially on the surface. Therefore, it's difficult to maintain pristine clean environment.

To maintain unidirectional airflow in the vertical direction, it is necessary to do these things:

- The air velocity of the blowing surface must be constant

- The wind speed of the suction surface of the floor return plate must be constant.

If the velocity is too low or too high (0.2m/s, 0.7m/s), there will be eddy currents.

At a speed of 0.5m/s, the airflow is more uniform.

The common air velocity of a cleanroom is between 0.25 and 0.5 m/s.