Negative pressure room and its applications

Air flows from higher pressure to lower pressure. High and low pressure or positive and negative pressure is applied to cleanrooms of many industries (pharmaceutical, medical, microelectronics, etc). They are used to prevent the spread of contaminants (in

Air flows from higher pressure to lower pressure. High and low pressure or positive and negative pressure is applied to cleanrooms of many industries (pharmaceutical, medical, microelectronics, etc). They are used to prevent the spread of contaminants (in positive pressure room) and contaminant leakage (in negative pressure room). In this article, we will learn about negative pressure room and its application.

Read more: Positive pressure room vs. negative pressure room

1. What is negative pressure room?

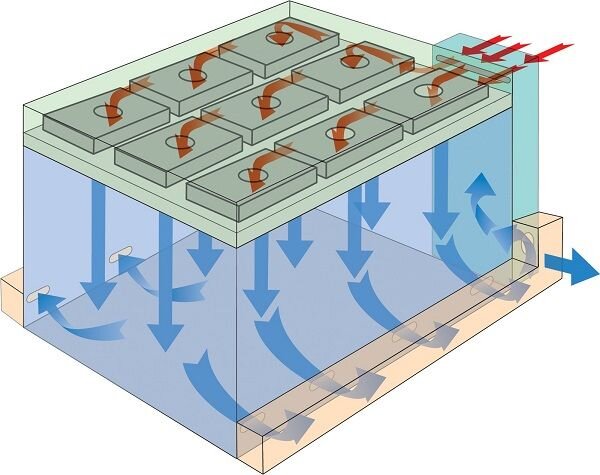

In a clean room, we can control the pressure using the airflow and direction of the air. Negative pressure cleanrooms will release more air than they provide to maintain lower pressure inside cleanroom than that of the surrounding environment. Negative pressure in the cleanroom helps to prevent any contaminants or toxic substances inside the cleanroom from escaping to the outside area.

Negative pressure is used where processes or substances can be hazardous and contaminated to other processes and the surrounding environment. Negative pressure can be used to limit the spread of harmful particles, fumes, or substances effectively in tandem with HEPA filtration and ventilation system.

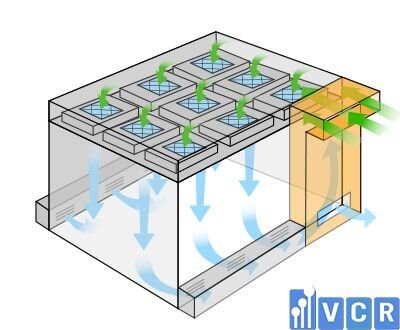

2. Negative pressure room working principle

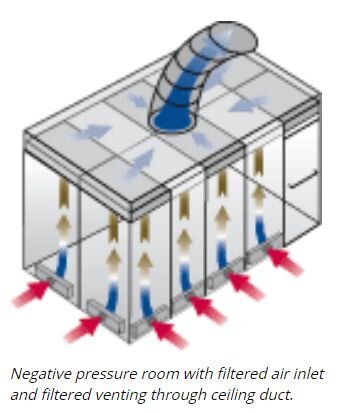

The negative air pressure is achieved by drawing air out of the cleanroom at a faster rate than the air supply. In most situations, air enters through filters near the floor and then is sucked out through filters in the room ceiling.

To ensure the negative pressure room (or negative pressure cleanroom) works properly, adjacent spaces must be maintained at a pressure higher than the room. A small difference in pressure will be effective in limiting contaminants. However, the larger the differential pressure is, the stronger the air moves to achieve equilibrium so that the contaminant moves in the opposite direction as much as possible.

Some cleanrooms only require a small level of negative pressure, while others require a high level to support the containment of hazardous liquids or gases. Depending on your intended use, higher differential pressure can be selected to limit the release of hazardous liquids or toxic fumes. In any case, having a pressure monitoring system is very important to ensure balance and consistency in your cleanroom.

3. Negative pressure in cleanroom

Negative pressure can be used in a cleanroom, or in part of a cleanroom design, such as inside the dispensing booth. The air exhaust will remove airborne contaminants, odors or fumes, and prevent harmful, hazardous substances from escaping into a negative-pressure space.

Negative pressure rooms are commonly found in pharmaceutical or medical research facilities that work with hazardous compounds or infectious particles. A negative pressure cleanroom is an example of a segmented cleanroom where other segments may meet different classification requirements or have different pressure, cleanliness, or operating process needs.

4. Negative pressure room application

Negative pressure cleanrooms are particularly useful in medical applications where work involves hazardous compounds, toxic fumes or infectious substances.

Hospital clean room

Hospitals use negative pressure clean rooms to contain airborne infectious substances, pathogens, and viruses. And a recent popular application is negative pressure rooms to treat patients who carry dangerous diseases (such as COVID 19).

In the research, treatment, isolation, negative pressure helps seal off dangerous contaminants to keep hospital staff and patients safe. Hospital cleanrooms often require negative pressure when treating patients, dealing with hazardous drugs or infectious diseases.

Medical research cleanroom

Medical research, especially involving hazardous substances, aerosol pollutants, or hazardous wastes, is often carried out within biosafety cabinets.

Negative pressure is used to prevent any harmful particles from escaping the room, where they can contaminate other spaces or pose a threat to human or animal life. Negative pressure rooms protect researchers from hazardous materials or substances in cleanrooms, where staff will be provided with appropriate protective equipment and care.

Pharmaceutical cleanroom

Pharmaceutical cleanrooms, especially those that comply with USP 800 standards for sterile and non-sterile mixtures of hazardous materials often require negative pressure for safe operation. It will enable safer handling of hazardous products and protection for employees and consumers.

Negative pressure rooms are particularly useful in many medical cleanroom applications. Some negative pressure rooms can also be found in other industries where hazardous materials need to be controlled.

Vietnam Cleanroom Equipment (VCR) specializes in providing cleanroom equipment for construction contractors.

We provide high-quality products with competitive prices and large quantities nationwide. The equipment includes:

Differential pressure gauge, FFU Fan Filter Unit, Pass box, Clean room air filter, HEPA box, Clean booth, cleanroom steel door, Isolator cabinet, and other equipment