The differences between cleanroom HVAC system and other HVAC systems

A cleanroom HVAC system is an essential component of any cleanroom environment. It is designed to maintain clean and controlled conditions within the room to prevent contamination. But what makes a cleanroom HVAC system different from other HVAC systems?

A cleanroom HVAC system is an essential component of any cleanroom environment. It is designed to maintain clean and controlled conditions within the room to prevent contamination. But what makes a cleanroom HVAC system different from other HVAC systems? In this article, we'll take a closer look at the key differences between cleanroom HVAC systems and other HVAC systems.

1. Air filtration

Cleanrooms require a much higher level of air filtration compared to other HVAC systems. The HVAC system in a cleanroom typically uses HEPA filters (High-Efficiency Particulate Air filters) or ULPA filters (Ultra Low Particulate Air filters) to trap even the smallest particles that can contaminate the environment.

Read more: HEPA filters and ULPA filters comparison

2. Controlled environment

Cleanrooms are designed to maintain a controlled environment with specific temperature and humidity levels. The HVAC system in a cleanroom must be capable of maintaining these within precise limits to ensure that the cleanroom environment is not contaminated.

3. Airflow control

Cleanrooms require controlled and unidirectional airflow to prevent particles from entering the cleanroom. The HVAC system in a cleanroom must be capable of maintaining a controlled and unidirectional airflow throughout the cleanroom environment.

Read more: Airflow in cleanroom: Laminar flow and Turbulent flow

4. Positive pressure

Cleanrooms are typically maintained at a positive pressure to prevent particles from entering the cleanroom. The HVAC system in a cleanroom must be capable of maintaining this positive pressure to ensure that the cleanroom environment remains particle-free.

5. Equipment Design

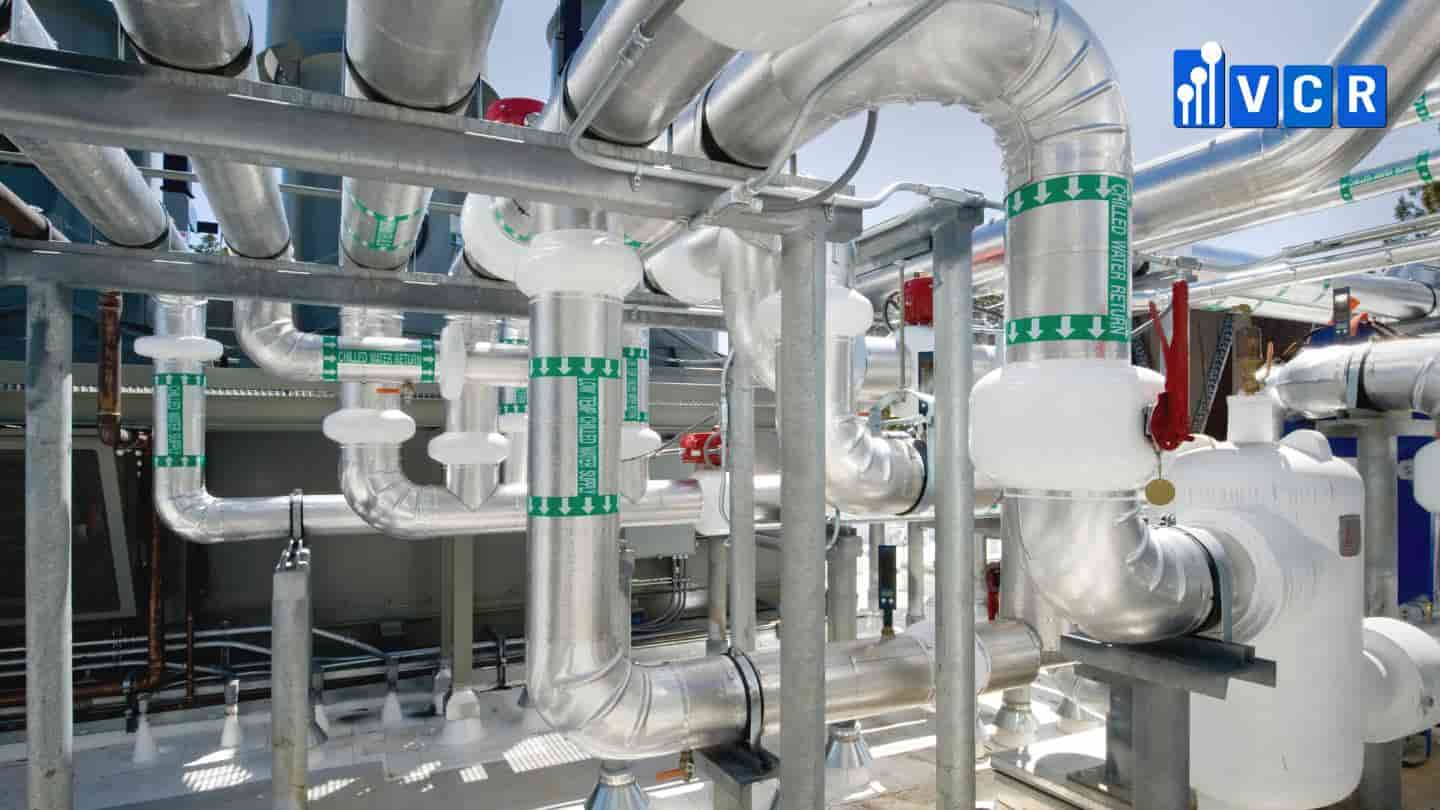

Cleanroom HVAC systems are typically more complex than other HVAC systems. They require specialized equipment, such as air handling units, air ducts, air filters, and temperature control systems. These components must be carefully integrated and maintained to ensure that the cleanroom environment remains controlled and contamination-free.

Cleanroom HVAC systems are designed with minimal surfaces and edges to prevent particle generation. The cleanroom equipment is also made of materials that won't off-gas or release particles into the environment.

6. Monitoring

Cleanrooms require ongoing monitoring of the environment to ensure that the HVAC system is functioning correctly. The HVAC system in a cleanroom must be equipped with sensors and monitoring equipment to ensure that it is operating within the required parameters.

To sum up, the differences between cleanroom HVAC systems and other HVAC systems are rooted in the level of control, filtration, and precision required to maintain a clean and controlled environment. Whether you're in the pharmaceutical, semiconductor, or biotech industries, a cleanroom HVAC system is a critical component of any cleanroom facility.