Pressure Drop In Air Filtration

Air filter pressure drop is one of the important factors to consider when choosing air filters in many applications. In this article, VCR will provide the basics about pressure drop in air filtration. Let's find out. 1. What is pressure drop? In

Air filter pressure drop is one of the important factors to consider when choosing air filters in many applications. In this article, VCR will provide the basics about pressure drop in air filtration. Let's find out.

1. What is pressure drop?

In filtration industry, "pressure drop" refers to the reduction in air pressure caused by using filter.

Air filters are used to trap the particles flowing through the filter. The more dense and tightly-knit an air filter’s material is, the more particles it will be able to trap. It is a trade-off in the density of a filter is that the filter will slow down your system’s airflow rate. This is known as an air filter pressure drop, and a high-pressure drop means that your air handler has to work harder and consume more energy in order to maintain proper airflow.

2. Initial & final pressure drop point

Initial Pressure Drop Point (sometimes called “Initial Resistance") is the pressure drop caused by a brand-new filter, a filter that has never been used. The Initial Pressure Drop of a filter will vary, based on the type, thickness, and efficiency of the filter.

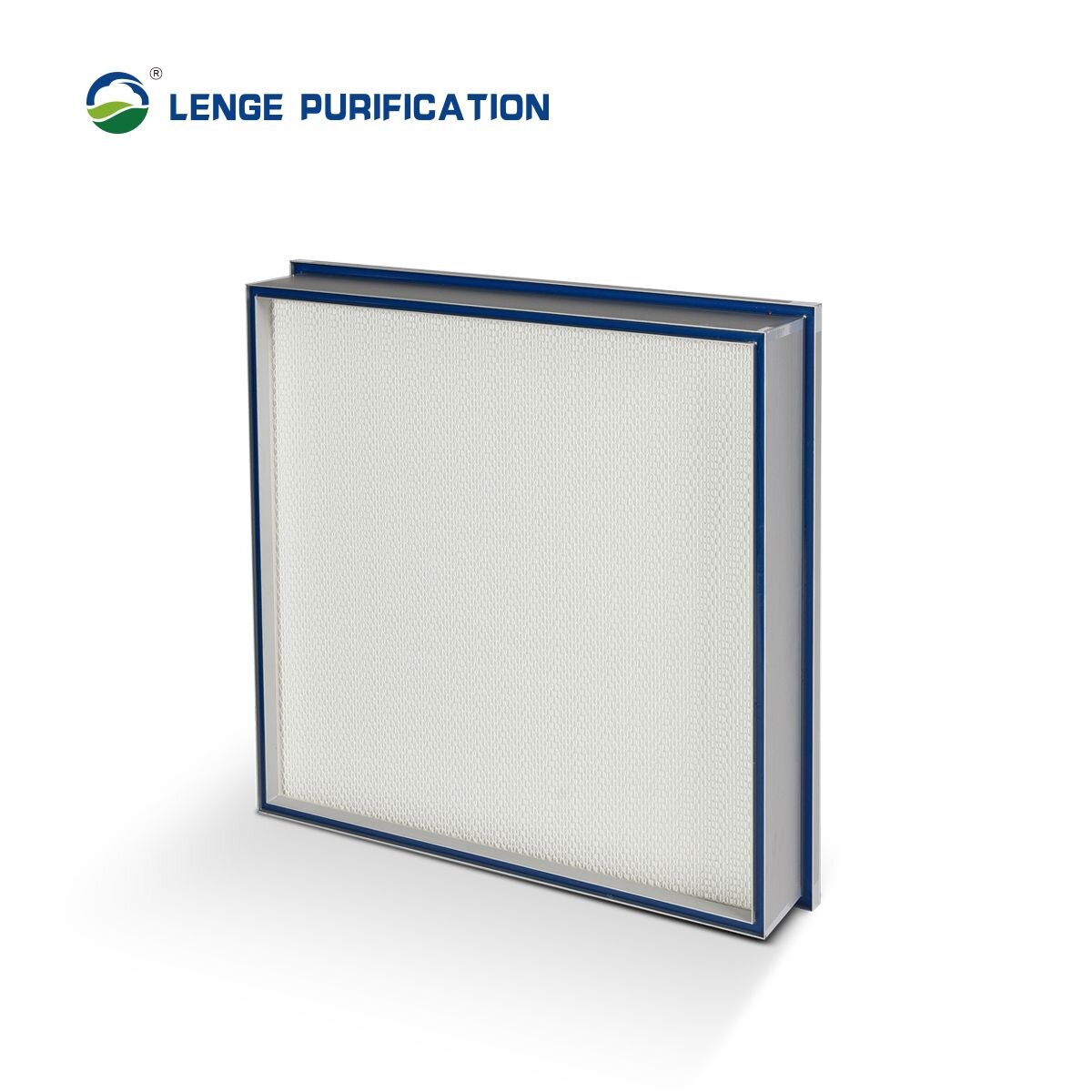

As a filter is used, it collects particles and gradually it becomes more difficult for air to pass through it – the pressure drop caused by the filter increases. Eventually, a filter will reach its Final Pressure Drop Point

Final Pressure Drop Point (sometimes called “Final Resistance.”) is the pressure drop at which a filter is meant to be replaced.

Example of air filter pressure drop:

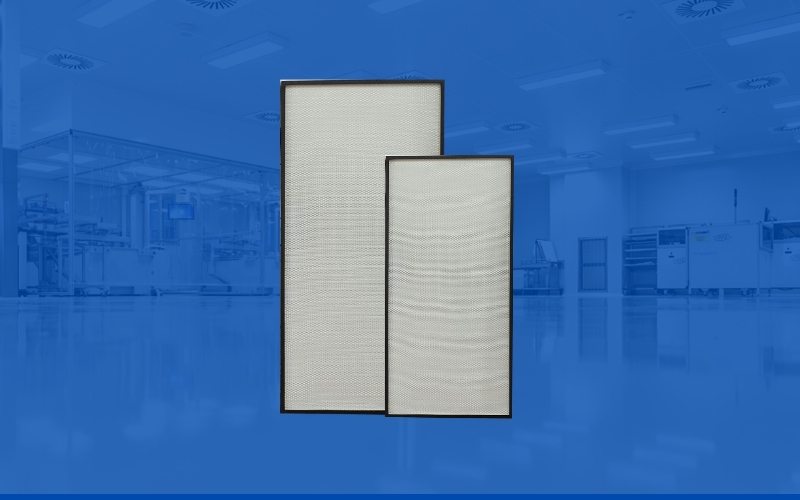

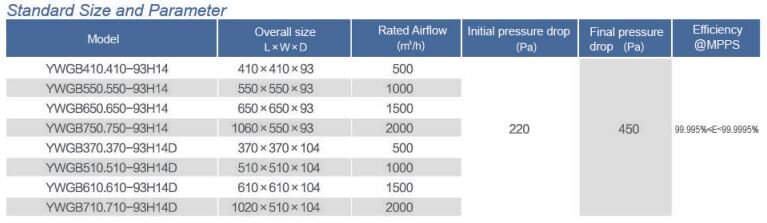

I have a dispensing booth in my cleanrooms. I install a YWGB410.410-93H14 filter, which I purchased from VCR, in my dispensing booth. I check my booth’s Pressure Drop indicator and see it has an Initial Pressure Drop of 220 Pa.

I use my dispensing booth for a few months and check the Pressure Drop indicator again. It reads 300 Pa. The specification sheet for my filter indicates it has a Final Pressure Drop of 450 Pa. I can still use my filter.

A month later, I check my Pressure Drop Indicator again. It reads 450 Pa. My filter has reached the end of its service life. I remove the filter, dispose of it safely and install a new filter.

3. Air filter pressure drop increases means that the filter becomes dirtier

It's important to remember that the pressure drop that air filters create only increases when the filter gets dirty. As dirt builds up on the filter, there is less and less space for air to flow through the filter. That’s a big reason that we remind our customers about the importance of checking, changing, or cleaning their filters regularly.

Vietnam Cleanroom Equipment (VCR) specializes in providing cleanroom equipment for construction contractors. We provide high-quality products with competitive prices and large quantities nationwide. The equipment includes:

Differential pressure gauge, FFU Fan Filter Unit, Pass box, Clean room air filter, HEPA box, Clean booth, cleanroom steel door, Isolator cabinet, and other equipment

For details, please refer to Vietnam cleanroom equipment official website

https://en.vietnamcleanroom.com