5 precautions of cosmetics cleanroom design

1. The unified principle In cosmetics cleanroom design, 5 elements including human, machine, material, method, and environment must be organically combined and fully balanced in each process. Once they are not unified, the operation is likely to be

Cleanrooms have become an integral part of the research and development, and production of cosmetics. Designing a cosmetics cleanroom requires different precautions from other types of cleanrooms. In this article, VCR will provide some precautions for designing a cosmetics cleanroom.

1. The unified principle

In cosmetics cleanroom design, 5 elements including human, machine, material, method, and environment must be organically combined and fully balanced in each process.

Once they are not unified, the operation is likely to be halted, which will take a lot of time to handle the operation problems.

2. The shortest distance principle

When designing and improving the cosmetic cleanroom layout, the moving distance and moving time must be minimized. Because the shorter the moving distance, the smaller the cost and time spent on material handling.

3. Uniform flow

To make sure the manufacturing process is efficient, and the material delivery is done smoothly without obstruction.

Pay attention to the layout design of the factory: try to avoid turbulent flow, otherwise, it will lead to a series of unexpected consequences, such as quality problems, management difficulties, production efficiency problems, safety problems, etc.

4. Safety

When designing a cosmetics cleanroom layout, it is necessary to ensure that the operations of the operators are safe and easy, reducing the fatigue of the work.

Please remember the movement and rotation of materials may cause safety accidents, and the actions of lifting and unloading goods may cause safety accidents.

5. Flexibility

A cosmetic cleanroom should be designed to adapt to the changes as much as possible, such as being able to flexibly respond to the increase or decrease in the process and the increase or decrease in production capacity.

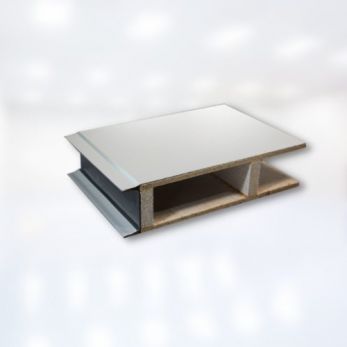

Vietnam Cleanroom Equipment (VCR) specializes in providing cleanroom equipment for construction contractors. We provide high-quality products with competitive prices and large quantities nationwide. The equipment includes:

Differential pressure gauge, FFU Fan Filter Unit, Pass box, Cleanroom air filter, HEPA box, Clean booth, cleanroom steel door, Isolator cabinet, and other equipment

For details, please refer to Vietnam cleanroom equipment official website