Advantages and disadvantages of cleanroom sandwich panel

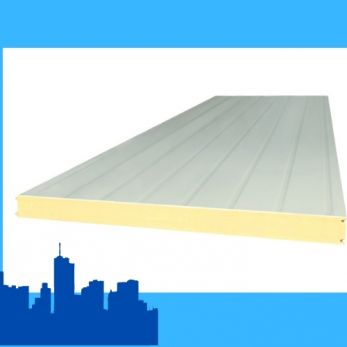

Nowadays, technology development has a huge impact on new construction solutions. In the construction industry, sandwich panel is considered the optimal solution for cleanrooms projects with outstanding features compared to traditional materials. However,

Nowadays, technology development has a huge impact on new construction solutions. In the construction industry, sandwich panel is considered the optimal solution for cleanrooms projects with outstanding features compared to traditional materials. However, this material has some drawbacks. In this article, VCR will address the advantages and disadvantages of cleanroom sandwich panel. Let's find out!

1. Advantages of cleanroom sandwich panel

Easy and fast installation

The panel is installed in a pre-assembled form, so the installation is quick and convenient. This helps to speed up the project, helping the constructors shorten to more than one-third of the construction time.

In addition, the installation of the cleanroom panel is simple, so it is not affected by weather conditions like rainstorms, etc. The projects made of panels can be easily dismantled, relocated or upgraded without affecting the surroundings.

Cost-saving

Using cleanroom sandwich panel could save up to 20% of investment costs while still ensuring the quality of the work. Cleanroom sandwich panel are up to 40% lighter than traditional building materials, which makes foundation consolidation simpler. In addition, the reduction of all beams and columns has reduced the investment cost compared to using traditional materials.

Sound-proof, flame-resistant, and heat-insulated performance

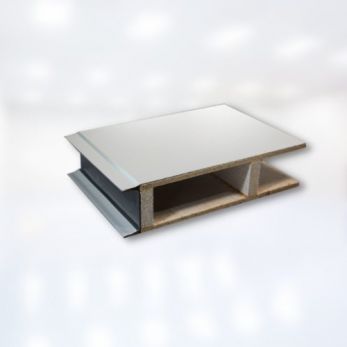

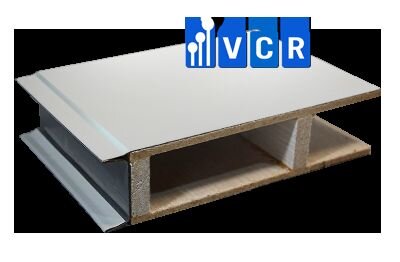

An outstanding advantage of cleanroom sandwich panel is the outstanding soundproofing, heat insulation, and fire resistance performance, which is much better than other materials. Due to the special 3-layer structure and a soundproofing core material in the middle, clean room sandwich panel is very convenient and suitable for buildings in urban or residential areas with high levels of noise pollution.

Besides, because the middle layer of material does not conduct heat, the insulation ability is very high. This feature is suitable for the vast majority of regions of our country with a hot summer climate in the North or a long dry season in the South. This advantage of the panel in construction is also significant in terms of saving energy costs for cooling compared to buildings built with traditional technology.

Cleanroom sandwich panel also has a very high insulation value because the middle layer of materials does not conduct heat. If you live in a place with a scorching summer temperature in North Viet Nam or a long dry season in South Viet Nam, then this material is for you.

Additionally, compared to buildings created with traditional techniques, the use of panels allows for significant cost savings in terms of energy expenditures for cooling

Due to the unique structure of the core material layer, the panel only shrinks and fades at high temperatures, but it does not ignite. That is the prominent feature that makes sandwich panel widely used in cleanroom construction, especially in adjacent regions or public buildings. Additionally, the panel's bearing structure can endure wind gusts up to 300km/h and earthquake aftershocks of up to 7.5 Richter.

Read more: Top 3 advantages of magnesium oxide panel

Beautiful appearance

Due to the reduction of the entire column and the main and auxiliary beams, the works from the sandwich panel have high aesthetics. More importantly, it will be convenient for the interior layout because it is not subject to entanglement and obstruction of columns or beams like traditional constructions.

High applicability

The broad range of current applications in offices, hotels, theaters to schools, hospitals, factories projects shows the high applicability of sandwich panels.

Environmental friendliness

Cleanroom sandwich panel is an environmentally friendly product because it is not moldy, and not attacked by termites, ants in hot and humid regions. Throughout the construction process, this type of material is very clean, while other materials such as cement, sand, gravel, ... cause environmental pollution.

2. Disadvantages of cleanroom sandwich panel

Cleanroom sandwich panel have many outstanding features but also have certain drawbacks such as:

- Panels have many types of high-temperature resistance, good heat insulation, soundproofing, and fire resistance, but some can only withstand average temperatures in the range of 35-75*C.

- Poor horizontal bearing capacity. Sandwich panel is not flexible in architecture with many angles, because pre-made foam panels and wire mesh cannot be bent or easily cut arbitrarily.

- Waterproof performance is not good, so it cannot be used at the base of the wall or the area that comes in contact with water …

Read more: Disadvantages of PU panel

3. Cleanroom sandwich panels supplier in Viet Nam

VCR - Vietnam Cleanroom Equipment is a unit specializing in providing cleanroom equipment for the construction of pharmaceutical factories, medical equipment, packaging, food, electronics, etc.

If you need cleanroom sandwich panel as well as other cleanroom equipment, please contact us via:

VCR - Vietnam Cleanroom Equipment

Address: N03-T7 building, Diplomatic Resident, Northern Tu Liem District, Hanoi.

Phone: +84 90 123 7008

Email: [email protected]

Website: en.vietnamcleanroom.com