9 things you should know about dynamic pass box

A dynamic pass box is a device for transferring items in a clean area to reduce the number of door openings. It is mainly used for the transfer of small materials in cleanrooms of different levels of cleanliness or the transfer of small items between

- Dynamic pass box structure

- 3 outstanding features of dynamic passbox

- Dynamic pass box working principle

- Dynamic pass box design requirements

- Material requirements for dynamic pass box

- Dynamic pass box qualification

- Dynamic pass box maintenance

- Precautions on HEPA filter replacement

- Precautions on dynamic pass box usage

A dynamic pass box is a device for transferring items in a clean area to reduce the number of door openings. It is mainly used for the transfer of small materials in cleanrooms of different levels of cleanliness or the transfer of small items between cleanrooms and non-cleanrooms.

This article will provide you 9 things you should know about dynamic pass box. Let's find out!

NỘI DUNG BÀI VIẾT

2. 3 outstanding features of dynamic pass box

3. Dynamic pass box working principle

4. Dynamic pass box design requirements

5. Material requirements for dynamic pass box

6. Dynamic pass box qualification

7. Dynamic pass box maintenance

8. Precautions on HEPA filter replacement

9. Precautions on dynamic pass box usage

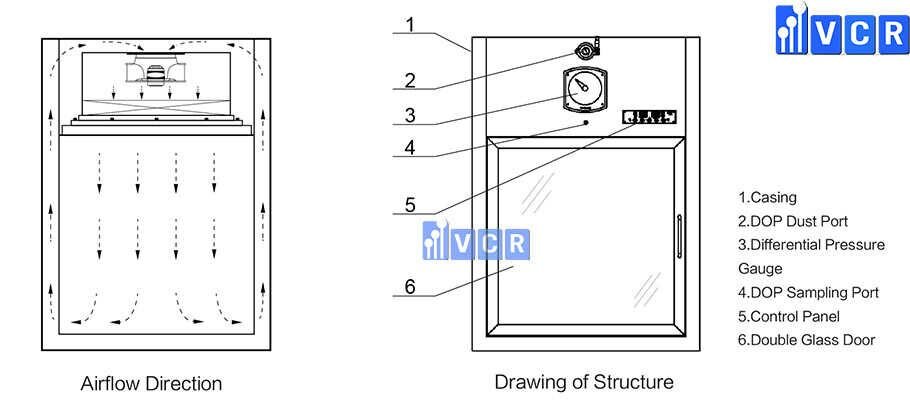

Dynamic pass box structure

Dynamic pass box consists of 5 parts: Casing, DOP dust port, differential pressure gauge, DOP sampling port, control panel, double-layer glass door.

Image: VCR dynamic pass box drawing

3 outstanding features of dynamic passbox

1. The dynamic pass box has self-cleaning function. When transferring items, the fan of the pass box sucks air inside through a HEPA filter to clean the interior of the dynamic pas box.

2. The dynamic pass box doors adopt electronic interlocking system. When a door is opened, the other door is automatically locked and prohibits humans from opening.

3. The dynamic pass box is equipped with ultraviolet disinfection lamps, which can disinfect items that cannot be disinfected with disinfectant.

Dynamic pass box working principle

Dynamic passbox includes HEPA filter, a fan and a return air grille. There is a ventilation gap between the inner liner and the outer frame of pass box.

When the fan inside pass box blows, it sends air to HEPA filter. The filter clean air enters the inner space of pass box, dilutes and filters the air inside. Then it passes through the return air grille, circulates to the fan, then goes through HEPA filter. The air is sent into the inner space and the cycle continues until the surface of the conveyed item is purified.

Image: Airflow in dynamic pass box

Dynamic pass box design requirements

1. Cleanliness requirements: Class B

2. The casing, as well as the chamber, are designed seamlessly and smoothly

3. Laminar airflow design. The air moves vertically from the fan then circulates inside the dynamic pass box.

4. Filter: G4 pre-filter and HEPA filter H13 or H14.

5. Air velocity: The air velocity through HEPA filter is controlled at 0.38-0.57 m/s (test placed below 150mm Hepa filter)

6. Differential pressure gauge for pass box is equipped to monitor the filter pressure difference (high-efficiency range 0-500 Pa / average efficiency 0-250Pa) with accuracy ± 5Pa.

7. Control system: On/off button; electronic interlock door button; UV light switch. When the two doors are closed, the UV lamp will be turned on.

8. HEPA filter (high-efficiency filter) can be disassembled and installed separately from the top box, convenient for filter maintenance and replacement.

9. A test port is located on the lower part of the dynamic pass box for fan maintenance.

10. Noise: Low noise

11. Diffuser plate: Stainless steel 304 plate is required

Image: VCR dynamic pass box

Material requirements for dynamic pass box

1. Surface material of dynamic pass box

The inner and outer surface of dynamic pass box should be made of stainless steel plate (stainless steel 304), the thickness of the plate is ≥1.5mm, the surface is polished and the surface finish is not less than RA 1. 2

2. Dynamic pass box frame material

The frame of dynamic pass box is made of 304 stainless steel, thickness ≥1.2mm, and the surface is polished, and the surface finish should not be lower than RA 1.2

3. Glass material

Dynamic pass box adopts tempered glass, and the thickness of the tempered glass thickness is greater than or equal to 8mm.

4. Corners

The corner is made of stainless steel (Inox 304), thickness ≥1.2mm, and the finish after surface polishing treatment should not be less than RA 1.2

5. Hepa Filter frame

The high-performance filter frame needs to be made of aluminum alloy to provide strength and shape to the filter.

6. Airflow diffuser plate

The airflow diffuser plate placed under the HEPA filter should be made of 304 stainless steel, plate thickness ≥1.0mm, and without burrs.

Dynamic pass box qualification

1. IQ - Installation Qualification:

It requires documentary evidence that dynamic pass box components have been installed in accordance with the requirements of the equipment purchase contract.

2. OQ - Operational Qualification:

It requires documented evidence that dynamic pass box components operate properly according to established standards and the parameters are within specified limits.

3. PQ - Performance Qualification:

It requires documented evidence that the dynamic pass box components and validated production process that meets quality standards under normal manufacturing conditions over a long period of time. Automated tests to clean and disinfect are carried out. Then, the tester will determine the time to confirm that the dynamic pass box meets GMP standards.

Dynamic pass box maintenance

1. According to the cleanliness of the environment, the filter should be replaced regularly (the pre-filter should be replaced from 1 to 6 months, and the HEPA filter should be replaced from 6 to 12 months), and the machine should be shut down during replacement.

2. Regularly (usually once every 2 months) use a particle counter to measure the cleanliness of the cleanliness area where this product is used to purify. If the measured cleanliness does not match the required cleanliness, the reason should be investigated (whether there is leakage, etc.) If the HEPA filter is worn, you should replace it with the new filter.

3. Sterilize the area regularly (usually a week). Especially, wipe the surface and UV lamp with gauze moistened with solvents such as alcohol or acetone to keep the surface clean.

4. When replacing the HEPA filter, the dynamic pass box opens the air outlet orifice. When replacing, pay attention to the arrow on the filter pointing to the laminar airflow direction.

5. After replacing the HEPA filter, use a laser particle counter to check whether the sealing of the frame is good, adjust the fan speed to keep the average air velocity in the operating area within the range of 0.3m/s to 0.6m/s, and then use laser particles counter checks the cleanliness.

6. Dynamic pass box only needs to be plugged in the power cord, and the equipment is on. When maintaining and repairing the equipment, be sure to unplug the power cord and confirm that the power is off before proceeding.

7. Non-professionals are strictly prohibited from touching the circuit board or adjusting the potentiometer of the pass box.

8. The differential pressure gauge is sensitive to temperature and grid voltage, and it needs to be used correctly for correct measurement.

9. When the differential pressure in the pass box is abnormal, wait for the fan to stop completely, restart the pass box and perform a self-check. At this time, it may automatically return to normal.

Precautions on HEPA filter replacement

- When replacing the HEPA filter, pay special attention to unpacking, handling, installation to ensure that the filter sheet is intact and undamaged. It is forbidden to touch the filter sheet.

- Before installation, point the new HEPA filter to a bright place and see with the naked eye whether there are leaks in the HEPA filter caused by transportation. If there are leaks, the filters cannot be used.

- When replacing the filter, the inspection panel should be removed first, then the bead, and then the filter should be taken out and replaced with a new one (note that the arrow mark should be in line with the airflow of the purification unit when replacing the HEPA filter), and install the pressure strip and the inspection panel according to the steps.

Precautions on dynamic pass box usage

1. Dynamic pass box must be used and stored in the room, not outdoors.

2. It is necessary to design cleanroom floor and wall structures that can support the weight of this equipment.

3. Do not look directly at the UV light inside the dynamic pass box to avoid damage to the eyes.

4. Do not open both sides of the door without turning off the germicidal UV lamp.

5. When replacing the UV lamp, it is necessary to cut off the power first and replace the lamp after the lamp has cooled down.

6. It is strictly forbidden to modify the product structure without the expertise to avoid electric shock and other accidents.

7. After the objects inside are cleaned, the receiver presses the switch to open the door.

8. Remove the item from the dynamic pass box and close the door.

9. When an abnormal situation occurs, it is necessary to stop the operation, disconnect the power supply and contact the technical staff or the manufacturer.

Vietnam Cleanroom Equipment (VCR) specializes in providing cleanroom equipment for construction contractors in Viet Nam. We provide high-quality products with competitive prices and large quantities nationwide. The equipment includes:

Differential pressure gauge, FFU Fan Filter Unit, Pass box, Clean room air filter, Dynamic pass box, HEPA box, Clean booth, cleanroom steel door, Isolator cabinet, and other equipment

For details, please refer to Vietnam cleanroom equipment official website