Airflow in cleanroom: Laminar flow and Turbulent flow

To construct a clean environment, we not only put clean and filtered air into cleanroom but also what happens to the airflow inside cleanroom. In general, the air in a cleanroom comes into 2 types: Turbulent flow and laminar flow. 1. Turbulent flow in

To design a clean environment, we not only put clean and filtered air into cleanroom but also control what happens to the airflow in cleanroom. In general, the air in a cleanroom comes into 2 types: Turbulent flow and laminar flow. This article will provide you the information about airflow patterns in cleanroom. Let's find out!

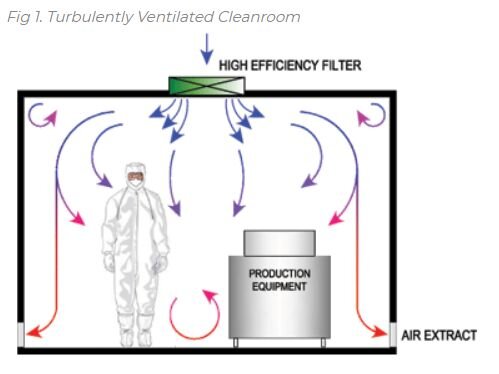

1. Turbulent flow in cleanroom

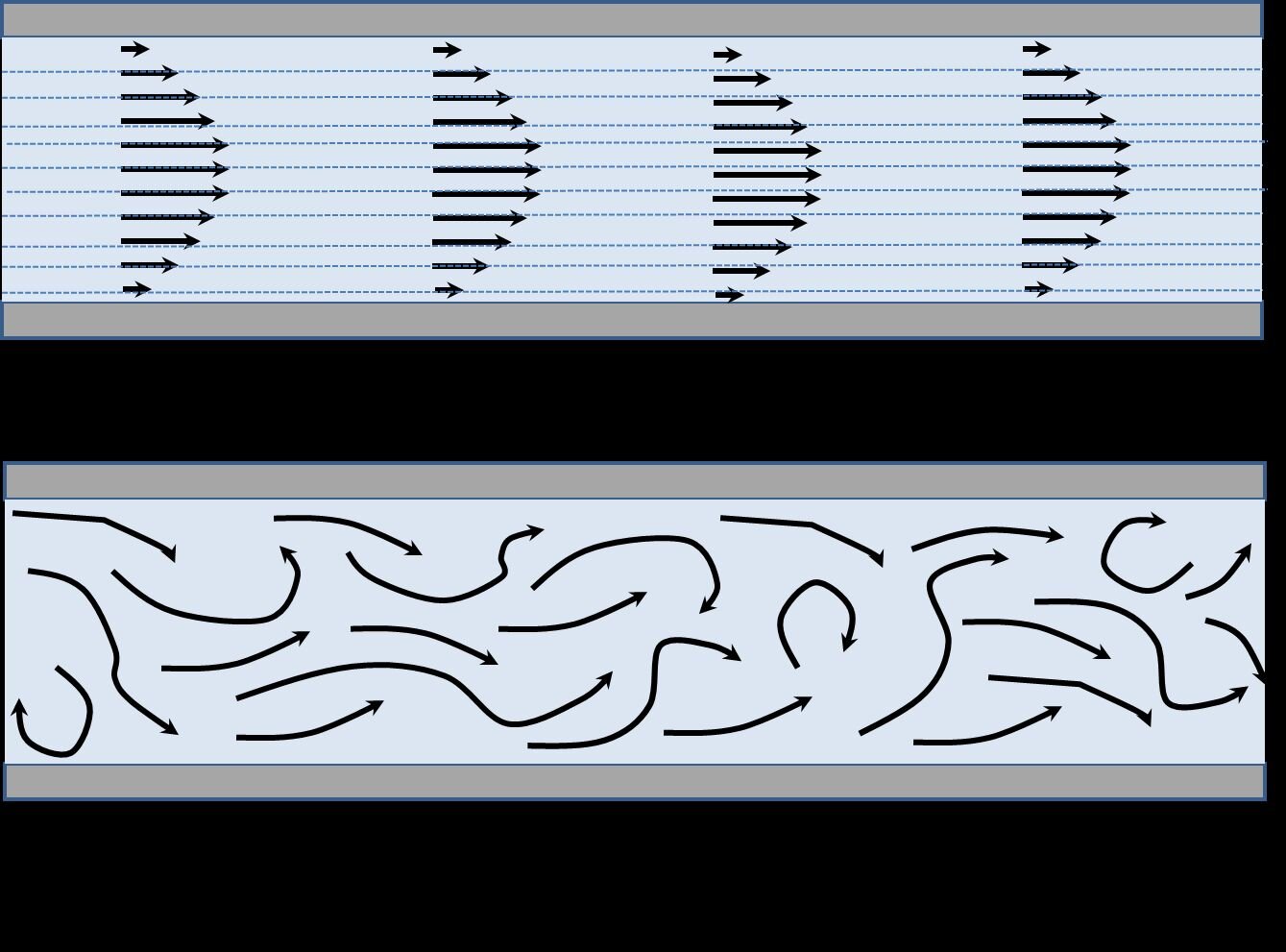

- Turbulent flow is by nature chaotic and unconfined. This means that the air mixes and swirls, perhaps forming eddies and vortices.

- The essence of turbulent flow is its lack of unidirectionality. Hence, turbulent flow is also called non-unidirectional or multidirectional flow.

- The main problem with turbulent air, with regard to contamination control, is that it can reduce the cleaning efficiency of our clean environment. To understand this, we must keep in mind that even the cleanest facilities will have a definite particle generation rate associated with the inside of the cleanroom. The incoming clean air must be able to sweep out this contamination. The presence of turbulence within the room will result in the removal of contamination being effectively slowed down or even stopped in some areas.

- Turbulent airflow is usually applied in ISO class 6 cleanroom, ISO 7 cleanroom, and ISO 8 cleanroom.

- If your company does not need high-class cleanrooms, turbulently ventilated cleanrooms are preferred.

(Image source: Spaceindustries UK)

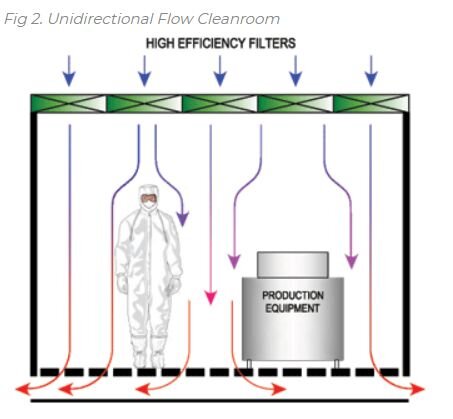

2. Laminar flow in cleanroom

- Laminar flow (or unidirectional flow) is best described as in which the streamlines remain parallel and uniform.

- Unidirectional flow is obviously the best choice for clean areas. Cleanroom ISO 1 to cleanroom ISO 5 employs laminar airflow. It is the most effective solution to cleanroom contamination.

- In the absence of any disturbing influence, like a rapidly moving object in the airflow, the air from our HEPA filter inlet, will be laminar if we limit its velocity to the range of 0.25 to 0.75 meters per second (approximately).

- The air velocity usually chosen for cleanrooms is around 0.45 meters per second (with a 20% tolerance). This unidirectional air will effectively sweep out contamination from our clean volume.

Source: "Cleanroom" book

Vietnam Cleanroom Equipment (VCR) specializes in providing cleanroom equipment for construction contractors. We provide high-quality products with competitive prices and large quantities nationwide. The equipment includes:

Differential pressure gauge, FFU Fan Filter Unit, Pass box, Clean room air filter, HEPA box, Clean booth, cleanroom steel door, Isolator cabinet, and other equipment

For details, please refer to Vietnam cleanroom equipment official website

https://en.vietnamcleanroom.com