Buffer area and its applications in clean room

To maintain cleanliness level, cleanrooms need a large amount of equipment and supporting tools. And one of the special elements that we need to know when building a cleanroom is a buffer room. What is a buffer room and how is it applied in clean area?

1. What is a buffer room?

+ A buffer room is a sterile area that lies between non-cleanrooms and cleanrooms, ensuring proper personnel entrance and reducing cross-contamination.

+ Buffer areas usually employ positive pressure to avoid the entrance of particle and microbial contaminants.

The differential pressure should be maintained between 10~20 pascals. HVAC system helps to maintain the pressure and the air quality of the area.

+ Buffer area should be surrounded by ISO 7 (class 10,000) or ISO 8 (class 100,000) area.

2. Buffer room applications

In the buffer room, doors cannot be opened at the same time. We can open the door when the other door is forcedly closed (due to the interlock system).

Standard cleanroom

+ The buffer room is a compounding area. Its function is to prevent particles and pollutants from penetrating into the cleanroom.

+ The buffer room is located between two clean rooms, it can have many doors (optional). One buffer room can be shared between two clean rooms.

+ If their classifications of two cleanrooms are too different, they cannot share a buffer room.

For example, ISO 8 cleanroom cannot share a buffer room with ISO 3 cleanroom.

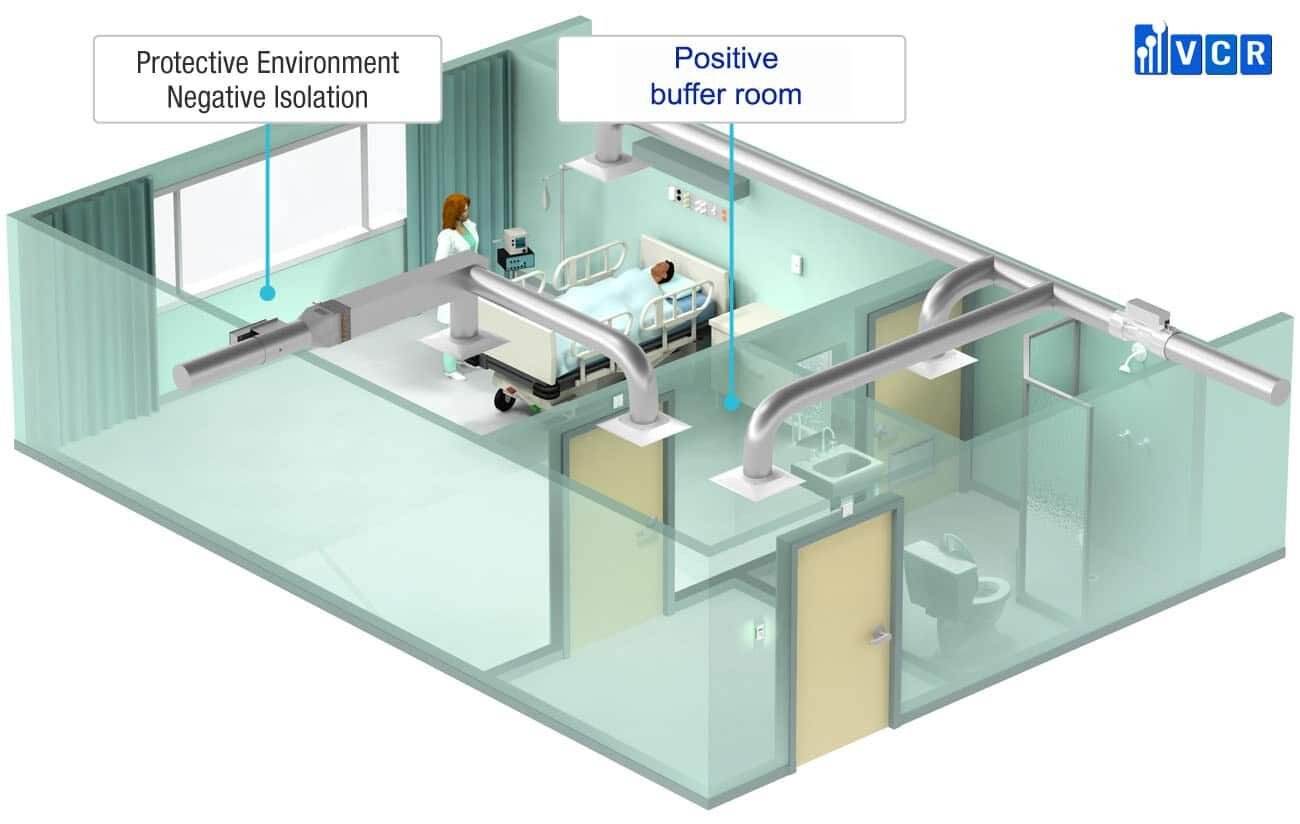

Negative pressure cleanroom

+ The negative pressure isolation room is composed of two parts: the buffer room and the main cleanroom.

The buffer room is a small room located between the corridor and the main isolation room.

The air from outside will pass through this room, and go into the negative pressure isolation room, then escape through the air filtration system.

Watch more about buffer room in negative pressure room:

+ People entering the negative pressure isolation room, such as medical staff, must go through a buffer room.

In this room, they will wear protective clothing, hoods, masks, gloves and shoes.

This ensures that the isolation room is kept free of contamination, helping to minimize the contact of healthy people with the patient's secretions such as saliva, nasal discharge, or droplets from coughs and sneezes.

Then, to ensure the unidirectional principle, the medical staff and the patient's family will leave the main cleanroom through a second buffer room.

Medical equipment and protective clothing will be removed and disposed of according to regulatory standards.

3. Buffer room design principles

+ The buffer room must not be less than 3 m2 in area.

+ The cleanliness level of the buffer room must be equal to the cleanliness level of the room (area) to enter, but not higher than ISO 6 (Class 1,000).

+ There is no need to arrange a buffer room between clean rooms that are separated by a level.

According to theoretical calculations, the pollution entering when opening the door does not increase if the dust concentration in the room is no more than 120% and the door is opened for less than 2 minutes.

+ Between cleanrooms having a difference between two levels of cleanliness, designing a buffer room should be considered comprehensively depending on the specific situations.

Although the pollution entering in at the moment of opening the door causes the dust concentration in the room to double, it only took about 3 minutes for the room to be clean again with dust concentration below 120%.

If self-cleaning time is considered to be acceptable or does not affect the experiment or production. In this case, it is not necessary to design a buffer room.

+ If adjacent rooms have different sources of contamination, even though they have the same cleanliness class, a buffer room should be arranged between them (separate rooms should be arranged to avoid pollution between them).

4. The importance of interlock in buffer room

The purpose of using the buffer room is to prevent cross-contamination of the cleanroom.

Therefore, besides creating clean air for this room, the buffer room must adopt an interlock system.

Interlock is a special lock that is used for access control of 2 doors at the same time to prevent cross-contamination between cleanrooms of different cleanliness levels. When a door is open, the other doors are automatically locked.

5. The difference between buffer room and airlock

In fact, there is still a big difference between the airlock and the buffer room.

+ The most important function of the airlock is to prevent the flow of air between adjacent rooms or environments, thereby effectively reducing "cross-contamination".

To prevent the egress of particles, the air pressure in the airlock room must be negative relative to the neighboring environment.

That means:

The air pressure in the airlock room must be lower than the air pressure in the adjacent cleanroom.

+ The buffer room is placed between the unclean area and the clean area.

The air pressure of buffer room will be higher than in the unclean area and lower than in the clean area.

The pressure from the unclean area to the buffer room to clean area varies from low to high.

Thanks to the buffer room, the airflow in the unclean area is blocked before entering the clean area, avoiding contaminating the clean area.

Simply put:

An airlock is a kind of buffer room. The buffer room has a clean air system, and the airlock does not.

Vietnam Cleanroom Equipment (VCR) specializes in providing cleanroom equipment for construction contractors. We provide high-quality products with competitive prices and large quantities nationwide. The equipment includes:

Differential pressure gauge, FFU Fan Filter Unit, Pass box, Clean room air filter, HEPA box, Clean booth, cleanroom steel door, Isolator cabinet, and other equipment