Dispensing booth working principle

Dispensing booth is one of the most essential purifying equipment in cleanroom. To ensure efficient operation of dispensing booth, operators should understand dispensing booth working principle. This article will identify the working principle of

Dispensing booth is one of the most essential purifying equipment in cleanroom. To ensure efficient operation of dispensing booth, operators should understand dispensing booth working principles. This article will identify the working principle of dispensing booths.

Dispensing booth (sampling booth or downflow hood) is a kind of purifying equipment for materials sampling, weighing, and analysis. Dispensing booth prevents the operators from powder contamination, thereby providing a safe and clean working environment.

Dispensing booths' user-friendly working environment and the high levels of protection they provide have led to their widespread adoption in the chemical, food, healthcare, and other industries.

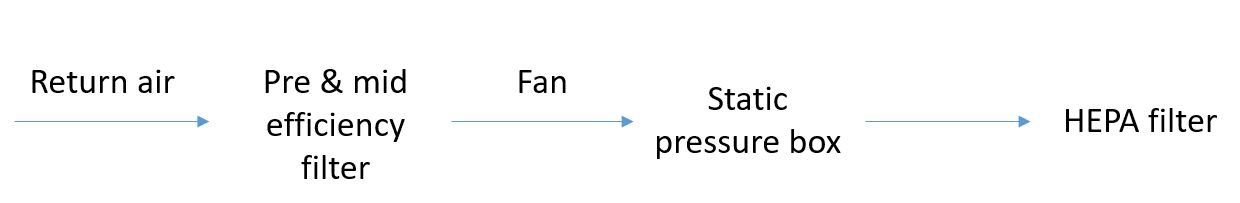

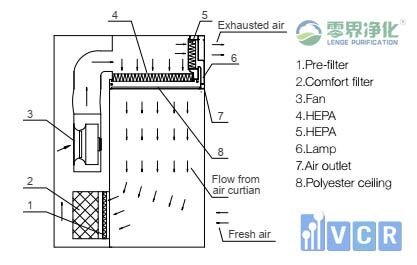

Below is the working principle of dispensing booth:

1. After the airflow is filtered by HEPA filter, the air supply and exhaust are free of residual dust, avoiding secondary pollution

2. The clean air is divided into 2 parts between the HEPA filter and the diffuser. 85% - 90% of the air flows through the diffuser and forms a uniform vertical laminar flow into the working area. 10%-15% of the air goes through the exhaust port, so the negative pressure of the working area is relative to the background area.

3. As the airflow in the working area is vertical laminar flow, the powder emitted by the working area is captured by pre-filter, medium filter and HEPA filter along with the streamline to avoid the impact on the operators.

Vietnam Cleanroom Equipment (VCR) specializes in providing cleanroom equipment for construction contractors. We provide high-quality products with competitive prices and large quantities nationwide. The equipment includes:

Vietnam Cleanroom Equipment (VCR) specializes in providing cleanroom equipment for construction contractors. We provide high-quality products with competitive prices and large quantities nationwide. The equipment includes:

Differential pressure gauge, FFU Fan Filter Unit, Pass box, Clean room air filter, HEPA box, Clean booth, cleanroom steel door, Isolator cabinet, and other equipment

For details, please refer to Vietnam cleanroom equipment official website