HEPA Box Working Principle

The working environment requirments for products produced in all industries, such as food processing industries, pharmaceutical industry, hospital operating rooms, etc are getting higher and higher.

The clean working environment requirements for products in all industries, such as food processing industries, pharmaceutical industry, hospital operating rooms, etc are getting higher and higher. Clean working environments are created by air purification system.

Air purification system is a system including fan (or air handling unit), air inlets, exhaust outlet, and ductwork. HEPA box is a terminal device, which has no power, relying on the air handling unit to supply air or exhaust air to achieve indoor air circulation. The ventilation cycle is performed by indoor positive pressure or indoor negative pressure. The air from air handling unit, through HEPA terminal box, sent in cleanroom can be filtered, detoxified, sterilized and so on.

When the indoor pressure required is positive, the fan starts to send air from the outside into the air duct and passes to HEPA terminal box. After filtering, clean and fresh air is sent into cleanroom. When the indoor pressure is higher than the outdoor pressure, the air is discharged from the air outlet and circulates in this way.

When indoor pressure is negative, the polluted indoor air will be discharged to the outside through the exhaust outlet, forming a negative pressure inside cleanroom, allowing the fresh outdoor air to enter the room through HEPA terminal box, so that the air in cleanroom reaches cleanliness requirements.

Working principle of HEPA terminal box

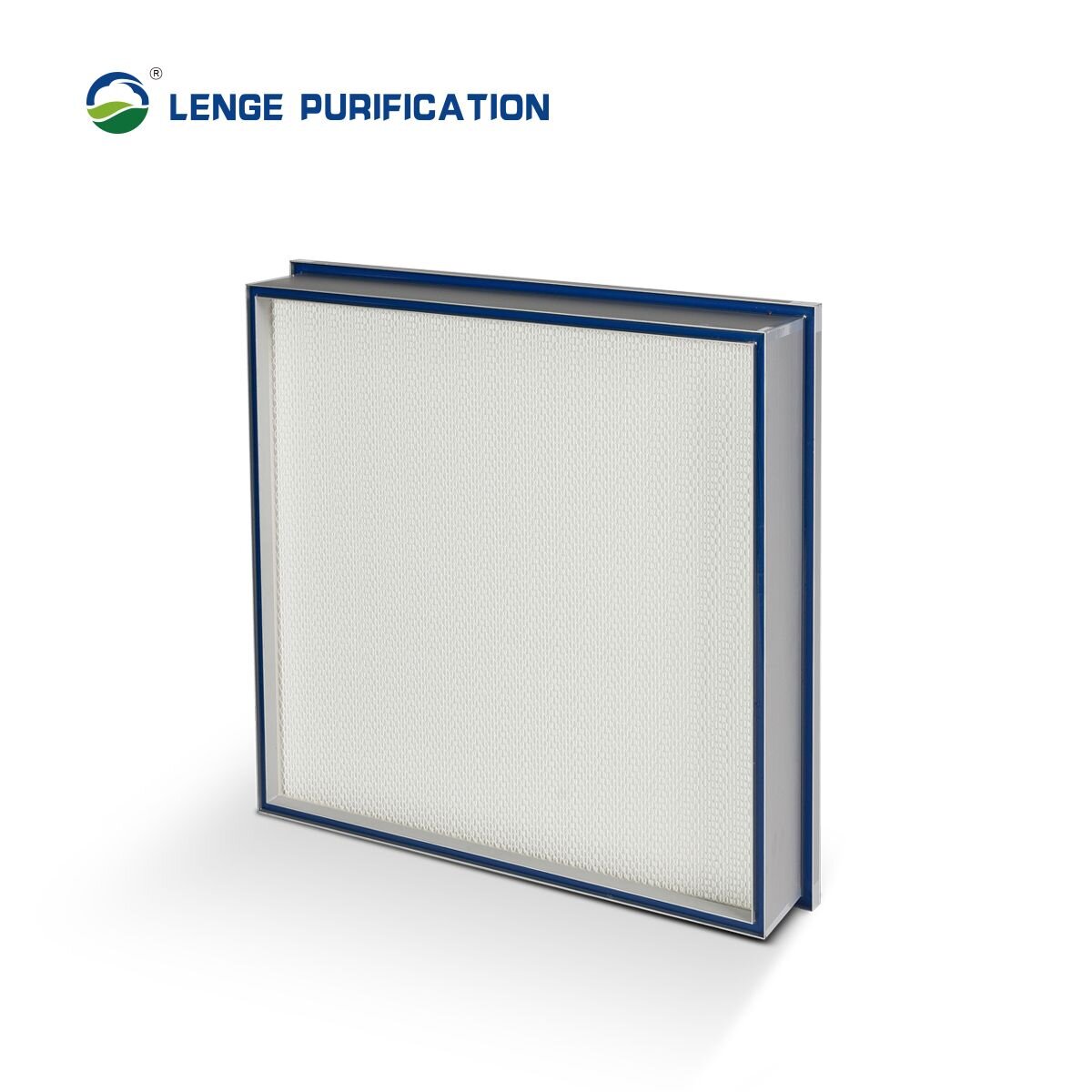

The removal of particles from the air is mainly accomplished by the HEPA filter in the HEPA terminal box. HEPA filters need to be replaced over a period of time. There are five main principles for trapping particles of a HEPA filter:

1. Interception effect

When particles of a certain size move near the surface of the fiber, the distance from the centerline to the surface of the fiber is less than the particle radius, and the dust particles will be intercepted by the filter fiber and deposited.

Dust particles in the air usually move according to an inertial motion or unspecified Brownian motion along with the flow of airflow, or they may move due to a certain field force.

Therefore, when dust particles collide with other objects in motion, due to the existence of Van der Waals forces (the force between molecules and molecular clusters) between the objects, it is easy for the particles to stick to the surface of the fiber.

The dust particles entering the High efficiency particulate air filter have more chances to hit the medium due to the laminar airflow supply from the HEPA box, but they will be stuck as long as they hit the medium. When the smaller particle collides with each other, it will bond to each other, thereby forming larger particles and sinking down. The final particle concentration of the dust in the air will appear to be relatively stable.

2. Diffusion effect

The Brownian motion of particles with small particle size is stronger and easily collide with the fiber surface.

Particles move inertially in the air due to the flow of airflow, but when they collide with disorderly arranged filter fibers, the airflow changes direction and the particles deviate from the direction due to inertial action, causing them to collide with the fibers and be affected.

The larger the particles, the more easily they collide, and the better its effect. Small particles make irregular Brownian motion. The smaller the particle size, the more violent the particle is when it is in irregular motion, the greater the chance of it hitting obstacles, and the better the HEPA terminal box filtering effect.

The particles <0.1μm in the air mainly subject to Brownian motion. The smaller the particle size, the better the terminal filtering effect. When the particle size is >0.3μm, the particle mainly performs inertial motion. The larger the particle size, the higher the terminal filtration efficiency.

3. Inertial effect

When the particle mass or speed is large, the particle will be deposited on the surface of the fiber due to inertia.

4. Gravity effect

When particles pass through the fiber layer, they are deposited on the fiber due to gravity sedimentation.

5. Electrostatic effect

Fibers or particles may be charged, generating an electrostatic effect that attracts particles, and the particles are attracted to the surface of the fiber.

Vietnam Cleanroom Equipment (VCR) specializes in providing cleanroom equipment for construction contractors. We provide high-quality products with competitive prices and large quantities nationwide. The equipment includes:

Differential pressure gauge, FFU Fan Filter Unit, Pass box, Clean room air filter, HEPA box, Clean booth, cleanroom steel door, Isolator cabinet, and other equipment

For details, please refer to Vietnam cleanroom equipment official website