How to remove contamination from cleanroom

Contamination is a threatening issue not only in our daily life but also a major threat to the cleanroom environment. Contamination in cleanroom could result in a ruined batch of pharma products or a malfunctioning piece of electrical equipment. In this

Contamination is a threatening issue not only in our daily life but also a major threat to the cleanroom environment. Contamination in cleanroom could result in a ruined batch of pharma products or a malfunctioning piece of electrical equipment. In this article, we will discuss how to remove contamination from cleanroom.

What should be done to minimize contamination?

In order to minimize contamination, first, we have to prevent the particles from making their way into cleanroom. There are 2 main contamination sources: external environment and human activities.

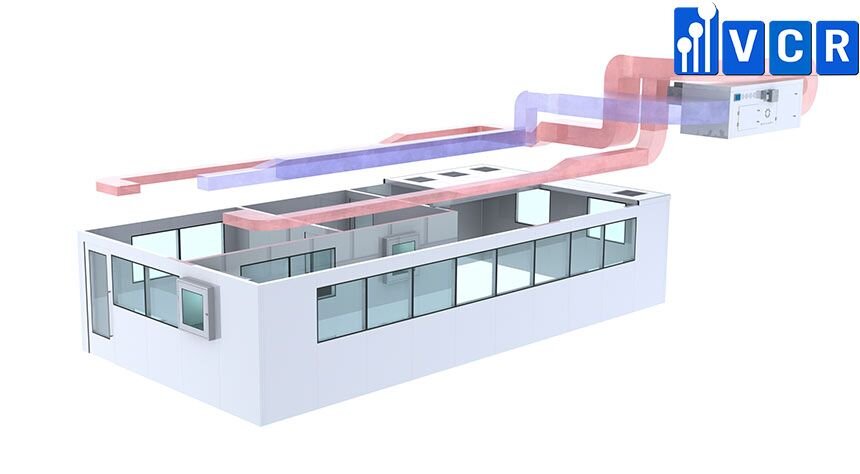

Then, check the performance of HVAC system and the integrity of HEPA filters. If it has been recently validated, then check the air changes per hour (ACPH) in the area according to the cleanliness of the room.

Next, check the airlock to ensure the integrity of the filters and ACPH. ACPH is a vitally important measurement for assessing the cleanliness of classified areas.

Personnel working in cleanroom have to conform to GMP standards. Clothes need to be cleaned and disinfected. Personal protective equipment needs to be kept in storage cabinets. Personnel has to disinfect hands before going into controlled environment.

Read more: Biocontamination control of clean rooms

How to remove contamination from cleanroom

If all the above observations are checked, then we should try to remove the existing microbial contamination from the area. An increase in the number of microorganisms in the cleanroom shows that we are not following the procedures properly. It clearly shows that we skipped a certain stage that needs to be followed.

There are a number of ways to minimize the microorganisms in cleanroom depending on the likely cause of the contamination.

1. HVAC system adjustment

Many businesses only run their HVAC systems during working hours to reduce their operating costs.

Cost savings are good but at the very least, we must “turn on” the HVAC system at least 1 hour before the manufacturing activities begin. It will remove existing contaminants from the area.

If the area is still over-contaminated, run the HVAC system continuously until desired results are achieved.

2. Floor cleaning

All dirt will eventually settle on the floor from the air, so proper floor cleaning is essential to keep them under control. Floors in the classified area should be cleaned twice in one shift. However, if the floor is not clean enough, it should be cleaned three times.

In addition, disinfectants used must be changed weekly and at least three disinfectants must be included in a rotating cycle. The choice of disinfectants must be made according to their uses. It means that all disinfectants must have a different mode of action. It will help minimize the chances of developing resistance in microorganisms.

3. Disinfectant spraying

Disinfectant is an effective way to reduce the number of bacteria in controlled areas because it directly affects the bacteria present in the air.

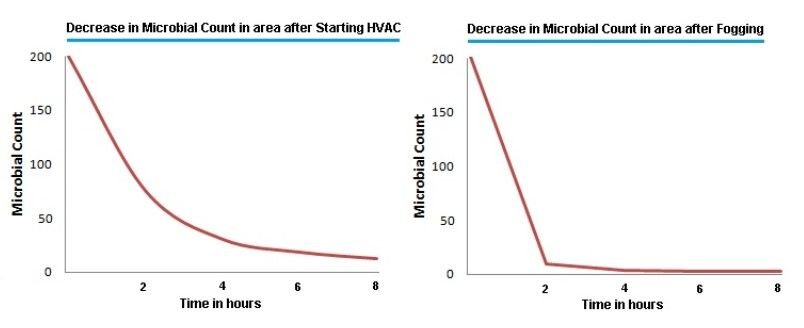

The spraying system will work on the floors, ceilings and walls of the area. The following graphs show the reduction of microbial contamination in the area after disinfection. Disinfectants containing silver nitrate and hydrogen peroxide are used.

Disinfectant spraying should be done for 15-30 minutes. The HVAC system should be turned off during this period.

Do not use IPA to spray as it is flammable and may cause a fire in your plant.

Read more: Contamination in cleanroom