How to check the quality of CAM gloves: CO, CQ, durability, chemical resistance

How to test the quality of CSM gloves is a key factor to ensure chemical safety and compliance in the pharmaceutical, chemical and cleanroom industries. With strong chemical resistance, high mechanical strength and outstanding ozone - UV resistance, CSM gloves need to be evaluated by CQ, CO, durability and chemical resistance.

- 1. What is CSM Gloves?

- 2. Certificate of Quality (CQ) for CSM Gloves

- 3. Certificate of Origin (CO) for CSM Gloves

- 4. Testing Mechanical Durability of CSM Gloves

- 5. Evaluating Chemical‑Resistance of CSM Gloves

- 6. Common Mistakes When Evaluating Incorrectly

- 7. Quick Answers

- 8. Need advice on choosing the right CSM gloves? Contact now!

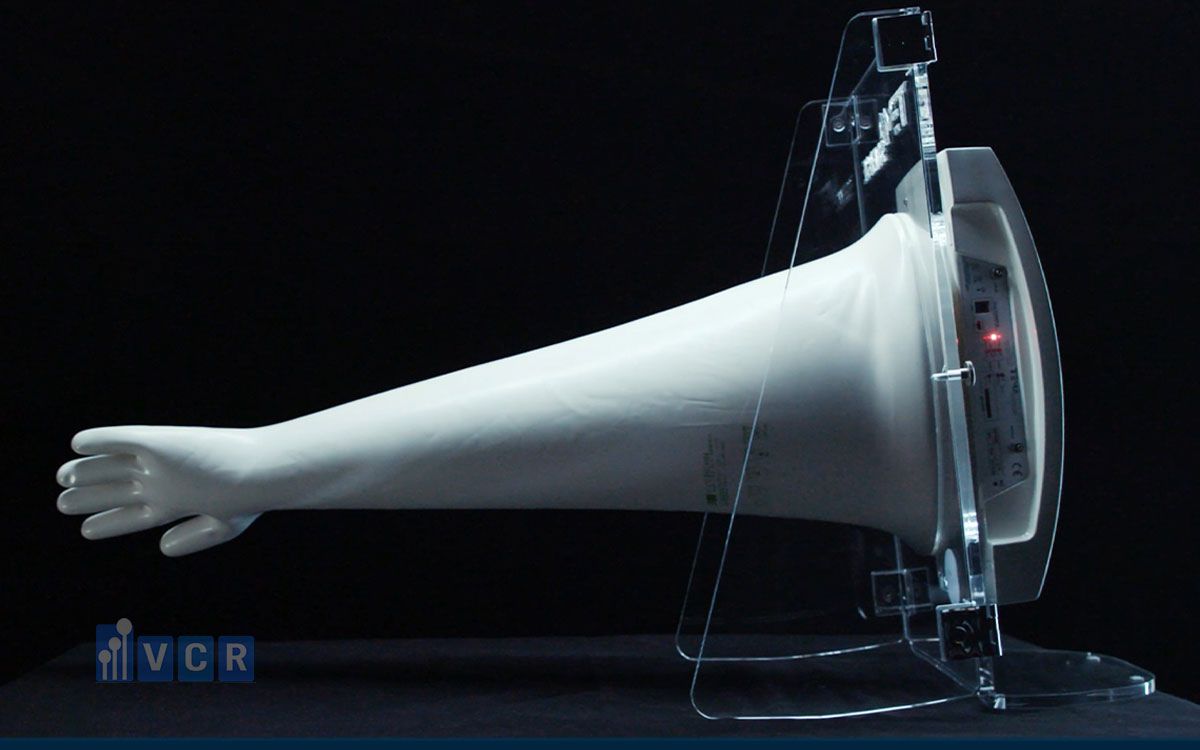

Gloves made from CSM material - with its strong chemical resistance, high durability and excellent mechanical strength - are the top choice in pharmaceutical, chemical and cleanroom environments. However, to ensure absolute safety and compliance with industrial standards, you should not just trust the manufacturer's advertising. This article guides you through the detailed quality check of CSM gloves, from certificates (CQ/CO), to durability and chemical resistance testing - helping you easily distinguish between qualified gloves and gloves with potential risks before putting them into use.

1. What is CSM Gloves?

CSM gloves are protective gloves manufactured from the material Chlorosulfonated Polyethylene (CSM) - a synthetic rubber known for its strong chemical‑resistance and outstanding durability. CSM is the trademark associated with products such as Hypalon, commonly used in industries needing high standards for chemical and mechanical safety.

Key characteristics of CSM material:

- Exceptional chemical resistance: capable of resisting many kinds of acids, alkalis, organic solvents and oxidizers.

- Superior weather, ozone and UV resistance: ideal for outdoor working environments or exposure to ozone in water treatment plants and cleanrooms.

- Strong mechanical durability: resistance to tearing and abrasion, retains elasticity under harsh conditions.

- Heat resistance and modest flame resistance: performs reliably in high‑temperature environments, and does not ignite as quickly as natural rubber.

With these characteristics, gloves made from CSM are often selected in sectors such as: chemicals, pharmaceuticals, cleanrooms, wastewater treatment, electronics manufacturing, and heavy industry.

2. Certificate of Quality (CQ) for CSM Gloves

What is a CQ?

A CQ (Certificate of Quality) is a quality certification issued by the manufacturer or supplier, affirming that the product meets the declared technical standards. For CSM gloves, the CQ is the evidence that the product satisfies both mechanical properties and chemical‑resistance requirements - critical in chemical, industrial and cleanroom environments.

The role of CQ in quality control:

- Ensures the product meets the declared quality.

- Provides a basis for incoming goods inspection.

- Supports internal audits or tender documentation.

- Builds confidence for GMP, ISO, HACCP audits.

Typical criteria listed in the CQ for CSM gloves:

|

Inspection criterion |

Purpose |

Unit |

|

Thickness |

Determines durability, sealing |

mm or mil |

|

Tensile strength |

Tests force resistance |

MPa or N/mm² |

|

Elongation at break |

Evaluates stretch and elasticity |

% |

|

Chemical‑resistance |

Defines safe exposure limits |

According to EN 374 / ASTM F739 |

How to read and verify a CQ properly:

- Check manufacturer information: name, address, logo must match the actual supplier.

- Match batch number: ensure the CQ corresponds to the gloves received.

- Review mechanical test values: compare with industry standards (e.g., EN 388, ASTM D412…).

- Verify chemical‑resistance values: look for specific chemicals and exposure times.

- Check for authorized signature and official stamp: a valid CQ must include these.

- Prefer bilingual CQ (English-Vietnamese): simplifies comparison in import/tender documentation.

3. Certificate of Origin (CO) for CSM Gloves

What is a CO?

A CO (Certificate of Origin) is a document issued by the authorized authority of the manufacturing country that confirms the product was produced in that country. For CSM gloves, the CO is a key document to:

- Determine preferential import tariff under trade agreements.

- Participate in public procurement or ODA projects.

- Demonstrate transparent origin and avoid counterfeits.

Why is CO necessary for import and bidding?

- Reduces import tariff if covered by a free trade agreement (e.g., Form E - China/ASEAN).

- Meets legal documentation for medical/cleanroom procurement.

- Provides competitive advantage in technical & commercial bids.

Common CO formats for CSM gloves:

|

CO Form |

Applicable origin |

Preferential tariff agreement |

|

Form E |

China |

ASEAN-China FTA |

|

Form D |

ASEAN countries |

ATIGA - ASEAN FTA |

|

Form AANZ |

Australia, New Zealand |

AANZFTA |

|

Form AK |

South Korea |

ASEAN-Korea FTA |

How to verify CO authenticity:

- Check official stamp and signature: authentic CO has embossed or clearly printed seal and proper signature.

- Cross‑check HS code: the HS code on the CO must match the HS code on the customs declaration and the invoice.

- Inspect the product description and manufacturer name: should be clear and specific, not vague like “Gloves”.

- Confirm the issuing authority: many country’s commerce chambers provide online verification of COs.

- Match invoice number: the CO must include the correct invoice number for the shipment.

4. Testing Mechanical Durability of CSM Gloves

Mechanical durability is a key attribute to evaluate the glove’s capacity to resist force, tearing and abrasion under practical working conditions. For CSM‑material gloves, testing must follow international standards to ensure accuracy and comparability.

Relevant standards applied:

|

Standard |

Description |

Applicable scope |

|

EN 388 |

Evaluates tear, cut, abrasion, puncture |

Protective gloves in industrial use |

|

ASTM D412 |

Tests tensile strength & elongation |

Rubber and elastomer materials |

Main test methods:

- Tensile Strength: Measures maximum force before the glove tears. Unit: MPa or N/mm². A typical minimum could be ≥14 MPa under ASTM D412.

- Elongation at Break: Measures how much length increases before breaking. Unit: %. Common values: 300‑500%.

- Abrasion Resistance: Measures number of cycles until material fails (per EN 388). Ratings from 1 to 4; Level 4 corresponds to ≥8000 cycles.

Practical significance:

- In chemical or wastewater treatment industries: You need gloves with high tensile strength and elongation to avoid punctures during aggressive handling.

- In electronics or light mechanical industries: High abrasion resistance ensures glove longevity when handling sharp or rough components.

- In cleanroom environments: Gloves must combine durability with flexibility for precise handling.

Note: Visual thickness alone is not a substitute for standardized mechanical data-always rely on test reports.

See more: CSM vs NBR Gloves Comparison: Which is Suitable for Pharmaceutical Manufacturing?

5. Evaluating Chemical‑Resistance of CSM Gloves

Gloves made from CSM are favored in chemical‑exposure settings due to their elevated resistance to acids, alkalis and many industrial solvents. However, accurate evaluation must rely on international standards and classifications.

Applicable standards for chemical resistance:

|

Standard |

Description |

Application region |

|

EN ISO 374‑1:2016 |

Classifies gloves according to chemical‑protection performance |

Common in the EU |

|

ASTM F739 |

Measures breakthrough time of chemicals through glove material |

Widely used in the US |

Glove classification levels:

- Type A: Resistant to at least 6 listed chemicals for ≥30 minutes.

- Type B: Resistant to at least 3 listed chemicals for ≥30 minutes.

- Type C: Resistant to at least 1 listed chemical for ≥10 minutes.

Gloves made of CSM often achieve Type B or even Type A depending on thickness and manufacturing formula.

Resistance table for some common chemicals:

|

Chemical |

CSM glove resistance |

Notes |

|

Sulfuric acid 98% |

Very good |

Does not break down surface |

|

Organic solvents (Toluene, Acetone) |

Medium to good |

Needs specific concentration check |

|

Sodium hydroxide (NaOH) |

Good |

Less degradation over time |

|

Methanol, Ethanol |

Medium |

Possible slight permeation after hours |

|

Hydrogen peroxide 30% |

Medium |

Use thicker glove for longer exposure |

Important considerations:

- Don’t assume one glove type suits all chemicals - always check manufacturer’s chemical‑resistance chart.

- Longer exposure time reduces effective protection - replace gloves regularly.

- Use CQ or technical sheet to verify resistance data for each specific chemical.

6. Common Mistakes When Evaluating Incorrectly

During the selection and evaluation of CSM gloves, many procurement or safety departments make errors that can lead to serious consequences such as wrong glove selection, shortened glove life or even safety risks. Here are three frequent mistakes to avoid:

1. Trusting fake CQ/CO documents

- Some unreputable suppliers may supply altered, fabricated or non‑matching CQ/CO documents.

- This can result in procurement of inferior gloves, misalignment with technical specifications and procurement/ audit failures.

- Mitigation: Always verify supplier credentials, cross‑check batch numbers and confirm CO via official authority websites.

2. Not checking against the industry‑specific standard

- Example: The pharmaceutical industry requires gloves with high cleanliness and light chemical resistance; heavy chemical industries require solvent‑resistant, thicker gloves.

- Common mistake: Choosing gloves because they are “cheap” or “general chemical‑resistant” without referencing actual standards like EN 374, ASTM F739, EN 388…

- Solution: Define the working environment and chemicals involved, then match those against the glove specification.

3. Misjudging actual chemical resistance

- Misconception: Thicker gloves = universally better, or glove not tearing = full protection.

- Reality: Each material has a specific chemical resistance profile; CSM resists acids/alkalis very well, but may not resist toluene or acetone as well as nitrile.

- Solution: Use the manufacturer’s chemical‑resistance table per EN 374/A or request actual breakthrough test data.

7. Quick Answers

Can CSM gloves be used in the food industry?

No, not recommended. While CSM offers strong chemical resistance, it typically does not meet certifications for direct food contact (e.g., US FDA or EU 10/2011), so it should not be used for food processing or packaging.

Is CSM more durable than nitrile?

It depends on the application. CSM gloves offer better chemical, ozone and weather resistance than nitrile, making them suitable for harsh outdoor or chemical‑heavy environments. However, nitrile gloves are more flexible and comfortable, making them better for precision tasks in cleanrooms or medical contexts.

Can I request the CQ from the supplier?

Yes. The customer has the right to request the original (or certified) CQ document from the manufacturer - especially important for bidding, internal audits or GMP/ISO verification.

8. Need advice on choosing the right CSM gloves? Contact now!

Need help selecting the right CSM gloves? Contact our VCR technical team for tailored consultation applied to your specific environment: chemicals, cleanroom, or specialized industries such as pharmaceuticals, wastewater, electronics.

We ensure products with full CQ, CO, detailed chemical‑resistance table and durability test data. Fast delivery - full support for quotes & bidding documentation.

Hotline: 090.123.9008

Email: [email protected]

Website: https://vietnamcleanroom.com/

Diep VCR