How much does it cost to regularly maintain an air filtration system?

The cost of regular maintenance of air filtration systems depends on the type of equipment, frequency of use, and industry standards such as GMP or ISO 14644. Understanding the cost components helps businesses budget appropriately, maintain air filtration performance, and extend the life of the system.

- 1. How much does regular air filtration system maintenance cost?

- 2. Why is regular maintenance of the air filtration system essential?

- 3. Key factors affecting air filtration maintenance costs

- 4. Reference cost table for air filtration system maintenance

- 5. How to optimize air filtration maintenance costs

- 6. Who should pay close attention to air filtration maintenance costs?

- 7. Consequences of neglecting regular maintenance

- 8. Need expert advice on air filtration maintenance costs? Let VCR help you!

1. How much does regular air filtration system maintenance cost?

The cost of maintaining an air filtration system varies depending on the type of equipment, usage frequency, and production environment. In general, it ranges from a few million to tens of millions of VND per maintenance cycle.

The price difference depends on several factors such as:

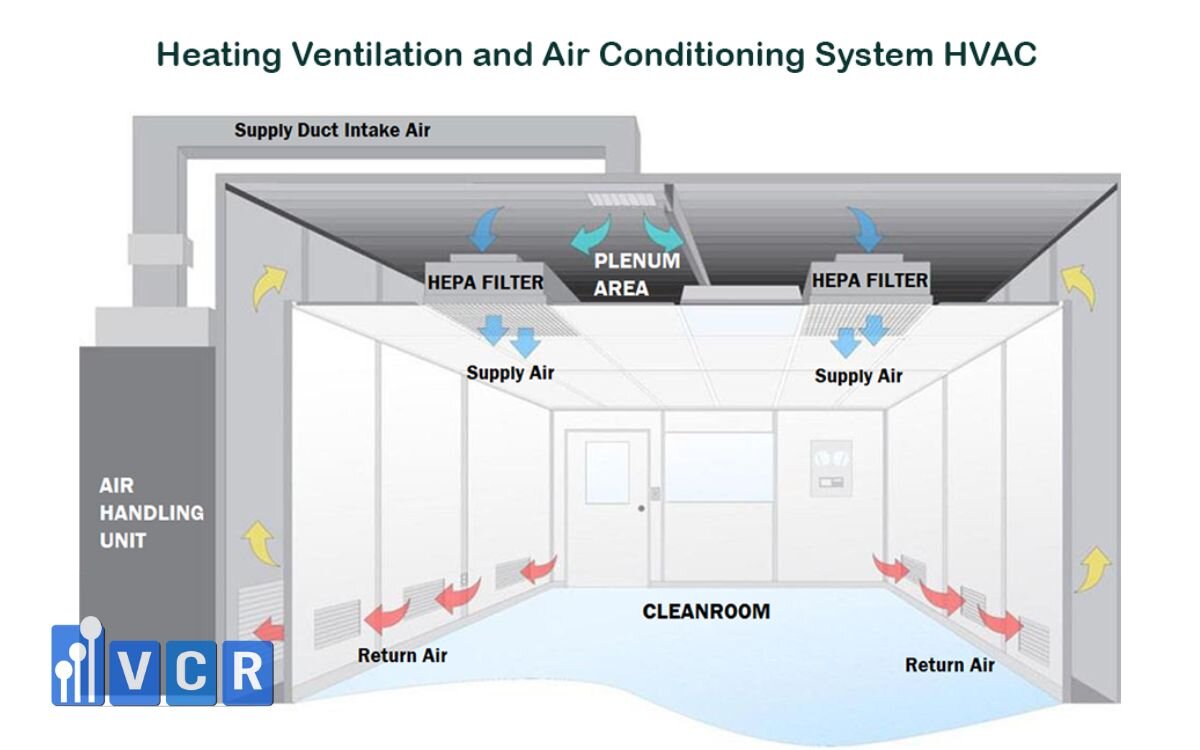

- Type of equipment: HEPA filters, FFUs, central HVAC systems, etc.

- Level of use: Facilities operating continuously with high production output require more frequent maintenance.

- Industry and environment: Sectors such as pharmaceuticals, food, and cosmetics have stricter cleanliness standards, resulting in higher maintenance costs.

If you are looking to estimate your maintenance budget or are unsure whether to handle it internally or hire an external service, this article will help you:

- Understand the key factors affecting air filtration maintenance costs.

- Access a transparent reference cost table.

- Learn how to optimize expenses while maintaining performance and compliance with GMP and ISO 14644 standards.

Keep reading to avoid common mistakes when planning filter maintenance - especially important for factories preparing for quality audits or production expansion.

2. Why is regular maintenance of the air filtration system essential?

The air filtration system is the “lungs” of a cleanroom - responsible for controlling dust, microorganisms, and airborne particles. Without proper maintenance, filtration efficiency drops rapidly, leading to serious risks in production and audits.

Here are the three main reasons why regular maintenance is mandatory, not optional:

1. Maintain filtration efficiency and protect product quality

Dust accumulation increases pressure drop and reduces clean air flow, resulting in:

- Lower filtration efficiency → higher risk of cross-contamination.

- Failure to meet ISO cleanliness standards → product quality issues.

Regular inspection and filter replacement ensure stable airflow, which is especially critical in areas such as weighing rooms, cosmetic filling lines, and food packaging zones.

2. Prevent equipment failures and costly repairs

Without maintenance, issues may include:

- FFU fan damage due to overpressure.

- Clogged filters disrupting the entire HVAC system.

- Forced production downtime for urgent repairs.

Unplanned repair costs are often several times higher than regular maintenance expenses.

3. Comply with GMP, ISO 14644, and HACCP standards

International standards require clear maintenance schedules and proper documentation:

- GMP - Good Manufacturing Practice (pharmaceuticals, cosmetics)

- ISO 14644 - Cleanroom classification

- HACCP - Food safety management

Failure to comply may result in audit failure and loss of export or distribution eligibility.

See more: Should we turn off the HVAC system in the cleanroom at night?

3. Key factors affecting air filtration maintenance costs

There is no fixed price for maintaining an air filtration system because costs depend on technical specifications and operating conditions. Below are the primary factors to consider when budgeting for maintenance:

1. Type of air filtration system

Each type of equipment requires specific maintenance procedures and costs:

|

Equipment Type |

Description |

Estimated Maintenance Cost |

|

HEPA/ULPA Filter |

Captures ultra-fine particles with high precision |

Replace every 6-12 months, cost 3-8 million VND/filter |

|

Prefilter, Medium Filter |

Coarse filtration, protects main filters |

Replace every 3-6 months, a few hundred thousand VND each |

|

FFU (Fan Filter Unit) |

Includes a fan motor, requires electrical and mechanical checks |

Service every 6 months, cost from 1.5 million VND |

|

Clean Bench, Air Shower |

Equipment with fan and control systems |

Regular inspection and filter replacement |

|

Central HVAC Filtration |

Complex system, requires professional maintenance |

High cost, depends on capacity and area |

2. Usage level and operating environment

Factories with dusty, humid, or continuous operations require more frequent maintenance:

- Food and cosmetics: Generate fine organic particles → filters clog faster.

- Pharmaceutical and lab environments: Require higher cleanliness (ISO 5-7, EU-GMP) → filters must be replaced on strict schedules.

- 24/7 production plants: FFUs and filters wear out faster, increasing annual maintenance costs.

Tip: Keep a pressure log for each filter stage to predict replacement time accurately.

3. Inspection and replacement frequency

Maintenance frequency directly affects annual cost variations:

- Filter pressure inspection: every 3-6 months.

- Prefilter replacement: every 3 months (or sooner in dusty environments).

- HEPA filter replacement: every 6-12 months, depending on pressure differential and performance.

- FFU and Clean Bench maintenance: twice per year.

Routine inspections allow early problem detection and timely replacement, helping reduce major repair costs and avoid production downtime.

4. Reference cost table for air filtration system maintenance

To help businesses - especially technical, procurement, and QA/QC departments - easily plan their budgets, below is an estimated cost table for common air filtration maintenance tasks:

|

Maintenance Task |

Suggested Frequency |

Estimated Cost per Service (VND) |

|

Filter pressure check |

Every 3-6 months |

500,000 - 1,000,000 |

|

Prefilter replacement |

Every 3 months |

300,000 - 700,000 |

|

HEPA filter replacement |

Every 6-12 months |

3,000,000 - 8,000,000 |

|

FFU (Fan Filter Unit) maintenance |

Every 6 months |

1,500,000 - 3,000,000 |

|

Full system cleaning |

1-2 times/year |

2,000,000 - 5,000,000 |

Important notes:

- The prices above are average estimates for medium-scale factories.

- Actual costs may vary depending on:

- Equipment type and filter brand.

- Industry: Pharmaceutical facilities tend to be more expensive than food or electronics.

- Maintenance service provider (in-house or outsourced).

- Companies should request detailed quotes for each system to make accurate budget forecasts.

See more: What is AHU? Structure and operating principle of the AHU system

5. How to optimize air filtration maintenance costs

While regular maintenance is essential, smart execution can help reduce costs while maintaining operational efficiency and regulatory compliance. Here are four strategies adopted by many GMP-ISO-certified facilities:

1. Establish a clear maintenance plan

- Set up schedules for inspections, filter replacements, and cleaning per zone (weighing room, airlock, filling area...).

- Keep logs of pressure and filter efficiency → detect anomalies early.

- Budget annually instead of reacting to breakdowns → proactive and cost-effective.

Tip: Integrate air filter maintenance into your internal quality management system (QMS) for streamlined processes.

2. Use high-quality filters - extend service life

- Cheap filters require frequent replacements and may damage downstream equipment (FFU fans, motors...).

- Choose HEPA or ULPA filters from reputable brands to extend service life to 12-18 months.

- Some prefilters can be washed 1-2 times before replacement → significant savings.

Upfront investment is higher, but long-term returns are much greater.

3. Apply automatic pressure monitoring systems

- Install digital pressure gauges at key filter points to:

- Alert when filters are clogged.

- Auto-log data for audits.

- Prevent unnecessary early replacement.

This is a preferred solution in GMP pharmaceutical and export-grade food plants for its efficiency and transparency.

4. Sign full-service maintenance contracts with professionals

- Specialized providers can:

- Schedule and execute maintenance on time.

- Report filter condition and recommend timely replacements.

- Minimize risks of missed checks or incorrect filter changes.

Providers like VCR offer annual packages at 20-30% lower cost than per-service requests - ideal for new facilities preparing for GMP/ISO audits.

6. Who should pay close attention to air filtration maintenance costs?

Air filter maintenance is not just a technical matter - it directly affects production efficiency, regulatory compliance, and brand credibility. The following departments should actively manage and control these costs:

1. Investors & Factory Managers

As key decision-makers on operational budgets, they should understand that:

Proper air filter maintenance ensures cleanroom integrity and reduces risks of downtime, equipment damage, or audit failure.

This is especially crucial for new facilities or those preparing for GMP certification.

2. QA/QC Department - Standard Compliance Officers

QA/QC is responsible for ensuring:

- Air quality consistently meets ISO 14644 standards.

- Systems are checked, recorded, and filters replaced on schedule.

- Maintenance logs and documentation are ready for audits (GMP, ISO, HACCP).

Cutting maintenance budgets may lead to audit failures, directly affecting compliance scores and export readiness.

3. Technical & Maintenance Teams

As the hands-on team, they must:

- Understand filter replacement cycles for each device type.

- Read pressure gauges and detect filter clogging.

- Coordinate with service providers for quick response to alerts.

Planning ahead - rather than replacing filters right before an audit - helps reduce emergency costs and operational stress.

7. Consequences of neglecting regular maintenance

Skipping or delaying air filtration system maintenance not only reduces performance but also creates serious risks for product quality, cost control, and certification.

1. Reduced filtration performance - Cross-contamination risks

Clogged filters increase pressure, reduce airflow, or cause leaks, compromising clean air control.

Dust or microorganisms may enter production zones → cause cross-contamination, product spoilage, or recalls.

2. Failure to meet GMP, ISO 14644, HACCP audit standards

Auditors will check:

- Is there a complete and timely maintenance schedule?

- Are pressure logs recorded regularly?

- Are filters replaced on a documented cycle?

→ Non-compliance may result in certification denial, barring the factory from exporting or partnering internationally.

3. Higher unplanned repair costs

Overloaded filters can burn out FFU motors, damage control boards, and force production halts.

Emergency repairs often come with high costs, long delays, and supply chain disruptions. In many cases, emergency repair costs are 3-5 times higher than planned maintenance.

8. Need expert advice on air filtration maintenance costs? Let VCR help you!

Are you unsure about:

- When to replace your HEPA filters?

- How to build a compliant maintenance plan for GMP?

- Whether to manage maintenance internally or outsource it?

VCR’s technical team offers free consultations:

- On-site system surveys at your facility.

- Filter selection tailored to your industry (pharma, food, cosmetics...).

- Detailed quotes by maintenance task.

- Maintenance schedules optimized for compliance and cost-efficiency.

Contact us today for a fast quote

Hotline: 090.123.9008

Email: [email protected]

Website: https://vietnamcleanroom.com/

Diep VCR