Causes of moldy HEPA filters in clean rooms

The reason why HEPA filters get moldy is not only due to humid environments or improper maintenance, but also due to substandard HVAC system design. When the “lungs” of a clean room are attacked by mold, not only does the filtration efficiency decrease, but it also directly threatens the sterility of the entire production area.

- 1. Reasons why HEPA filters develop mold in cleanrooms

- 2. Role of the HEPA filter in a cleanroom system

- 3. The real causes of HEPA filter mold in cleanrooms

- 4. Consequences when a HEPA filter develops mold

- 5. Standard procedure when discovering a mould‑infested HEPA filter

- 6. Preventive measures for mould in the air filtration system

- 7. Frequently Asked Questions

1. Reasons why HEPA filters develop mold in cleanrooms

When the "lung" of the cleanroom becomes mold‑infested

In a cleanroom system, the HEPA filter (High Efficiency Particulate Air Filter) is considered the “lung” of the entire production line. It is the final device in the airflow filtration chain, responsible for capturing ultrafine particles and microorganisms before the air is supplied into the production area. However, in recent years, our engineering teams at VCR have observed a worrying phenomenon: HEPA filters becoming mold‑infested increasingly often, even within areas considered “the cleanest.”

Images of black or green mold spots on filter surfaces, the characteristic damp odor emitting from the air supply system, are not just aesthetic issues-they serve as red flags indicating that the entire clean environment is jeopardized. Because if the final filter has been infiltrated by microbes, that means the airflow into the production area may carry millions of mold spores, undermining the ultra‑sterile equilibrium that is strictly controlled.

The question arises: Why can a device housed in the cleanest zone, protected the best, become a potential “mold nest”? Why would a filter rated at 99.97% @ 0.3 µm lose efficacy after only a few months of operation?

The answer lies not only in the filter itself, but also in the entire HVAC ecosystem, maintenance procedures and cleanroom operational practices. In this article, VCR will explore five core cause‑groups that lead to HEPA filters developing mold - from humidity factors, airflow, cleaning procedures, to materials and operational habits. We will also present remediation solutions, safe handling protocols, and long‑term preventive measures to help engineers, QA/QC teams and production managers maintain systems compliant with GMP/ISO 14644 standards and ensure that “clean” air is truly clean.

2. Role of the HEPA filter in a cleanroom system

If a cleanroom is likened to a living organism, the HEPA filter is its “lung,” and the HVAC system is its circulatory system. The HEPA filter not only performs ordinary dust filtration, but it is the final line of defense-determining whether the air delivered to the production zone truly meets “clean” standards under GMP, ISO 14644 or HACCP.

When this filter encounters a problem-especially mold infestation or moisture accumulation-the entire downstream clean‑air system is impacted: filter efficiency drops, pressure differentials shift, and microbes gain an opportunity to migrate back into the production zone.

2.1. Construction and operating principle

A standard HEPA filter typically comprises:

- Filter frame: Made of galvanized steel, aluminum or stainless steel (usually SUS304 in pharmaceutical, cosmetic or microbiological factories) for moisture resistance, rust protection and ease of cleaning.

- Filter media: Ultra‑fine micro glass fiber paper, pleated to maximize surface area, capturing particles down to 0.3 micron (about 1/200 the diameter of a human hair).

- Sealing gasket: Usually made of EPDM or silicone to ensure an airtight seal between the frame and system ductwork.

- Sealant: A heat‑resistant adhesive (often inorganic adhesive or epoxy) to secure the filter media and prevent moisture ingress.

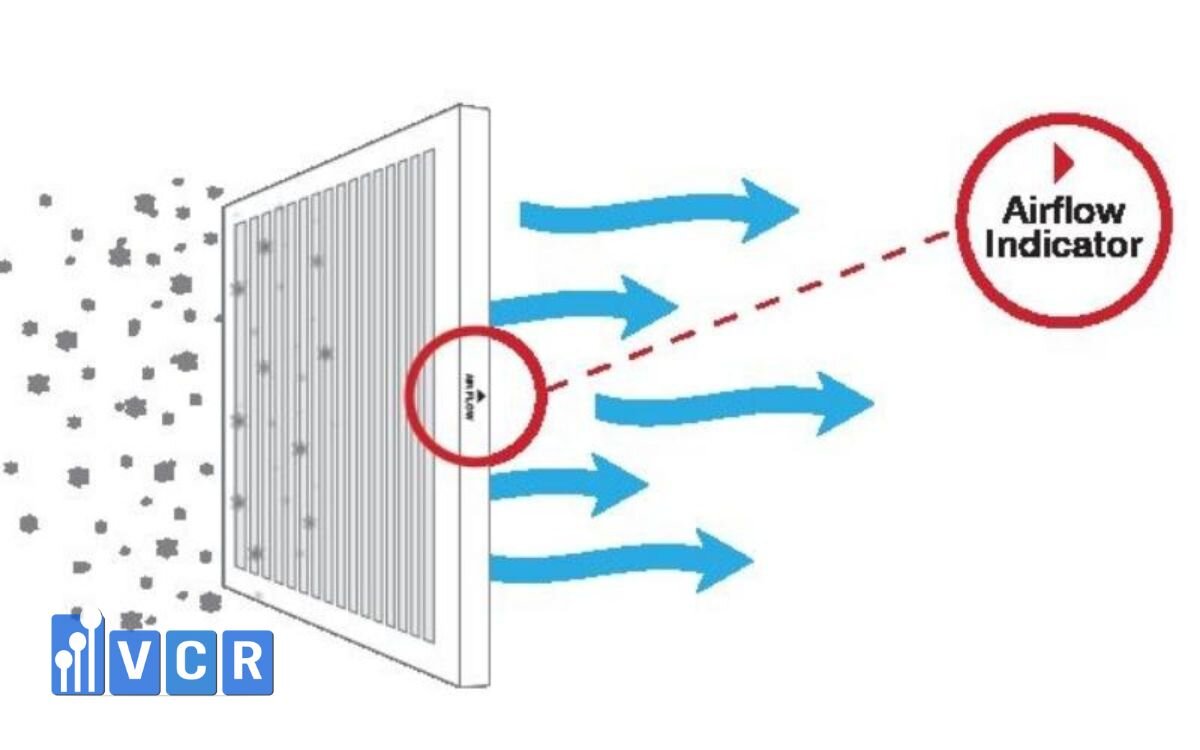

The filtration principle is based on three mechanisms:

- Impaction: Large particles impact onto filter fibers.

- Interception: Medium particles are intercepted when passing near a fiber.

- Diffusion (Brownian motion): Ultrafine particles zig‑zag randomly and get trapped on fibers.

With a filtration efficiency of ≥ 99.97% @ 0.3 µm, HEPA filters effectively remove ultrafine dust, pollen, bacteria, and even mold spores from airflow.

HEPA filters are installed at various points within a cleanroom system depending on the grade and design:

- In the AHU (Air Handling Unit): to filter the air before supplying into clean zones.

- Integrated into Fan Filter Units (FFUs): often used for ISO 5-7 cleanrooms.

- HEPA Boxes mounted in ceilings: for areas requiring laminar flow in pharmaceutical, cosmetic or microbiological production.

- Clean ceilings (Clean Ceiling systems): for high‑flow zones that are easier to maintain.

2.2. Why are HEPA filters vulnerable to humidity?

Although HEPA is considered the final protective barrier, the filter media (glass fiber) is highly sensitive to humidity. When relative humidity (RH) exceeds 65%, water vapor begins to condense on the fiber surface, softening the media, reducing rigidity and compromising particle capture efficiency.

Especially in low‑airflow zones or areas with uneven air circulation, moisture easily settles in “dead zones” - places where airflow is stagnant. It is exactly in these zones that mold spores from the environment can attach and grow rapidly-particularly when the ambient temperature is between 22-28 °C, which is ideal for mold development.

This phenomenon is more likely to occur when:

- The HVAC system runs intermittently (switched off overnight or on weekends).

- The HEPA filter becomes clogged, reducing airflow and causing local humidity to rise.

- The filter gasket or housing is compromised, allowing humid air from outside to infiltrate.

As a result, within just a few weeks, you may observe tiny black spots forming on HEPA surfaces, which then spread-signaling active mold growth.

In practice, VCR engineers have documented numerous cases where HEPA filters aged just 3-6 months already became mold‑infested because:

- There was no automated RH control in the system.

- Ductwork lacked proper insulation, leading to condensate formation.

- Return air streams mixed with humid air from auxiliary zones.

This indicates that protecting HEPA filters from mold cannot be limited to the device alone-it demands controlling the full clean‑air chain from the AHU to the final supply point.

2.3. Relationship between HVAC system and mold risk

To understand why HEPA filters can develop mold, one must view the entire HVAC‑to‑filter chain.

The HVAC system is responsible for controlling temperature, humidity, airflow and pressure. If any of these parameters deviate-especially the dew point-water vapor will begin to condensate in the ductwork or on HEPA surfaces.

The airflow path from AHU → duct → HEPA box → production area, if not properly controlled, becomes a “moisture highway,” carrying microbes and mold spores. If any link in the chain weakens (for example: dirty cooling coil in the AHU, condensate tray poorly drained, clogged prefilters), the whole system can become a source of mold propagation.

In reality, VCR engineers have observed HEPA filters becoming mold‑infested after only 3-6 months of operation due to:

- Lack of automated RH control systems

- Improper duct insulation causing condensation

- Return air mixing with humid air from auxiliary areas

This shows that safeguarding HEPA filters from mold requires more than just the component-it necessitates full‑chain control from AHU through to supply outlet.

See more: Common errors when using asynchronous FFU

3. The real causes of HEPA filter mold in cleanrooms

The phenomenon of the HEPA filter developing mold is not merely a random occurrence. It is the result of multiple technical and operational factors accumulating - from humidity, HVAC systems, maintenance cycles, to materials and the production environment. Below are six major cause‑groups identified through surveys of hundreds of GMP‑certified factories in Vietnam conducted by VCR.

3.1. Humidity in the room exceeds allowable limits

Relative humidity (RH) is a leading culprit causing mold in air‑filtration systems, especially at HEPA boxes or FFUs. When RH exceeds ~65% for extended periods, water vapor begins to adhere to the glass‑fiber filter media. These fibers have capillary structures that easily retain moisture, turning the filter media into an ideal environment for mold spores to proliferate.

In numerous facilities, the AHU (Air Handling Unit) and dehumidifier systems are not regularly inspected. Sensor errors of a few percentage points in humidity can render the control system inaccurate. Particularly, low‑grade clean zones (ISO 8-9) are often overlooked in humidity monitoring due to the belief that they are less critical. Ironically, this neglect allows mold to emerge in less‑scrutinised zones before migrating along the airflow path into cleaner zones.

An internal VCR study revealed: among 10 GMP pharmaceutical factories with HEPA filter mold incidents, 8 had average humidity >65%, especially during the rainy season.

3.2. Ventilation system not operating continuously

One of the most common operational mistakes is shutting down the HVAC system overnight or over the weekend to save electricity. However, when air in the cleanroom is stagnant, humidity accumulates rapidly - especially within technical ceiling spaces, AHU plenum, and inside the HEPA box.

In this “dormant” state, stagnant air becomes a micro‑climate ideal for mold spore germination. When the system restarts on Monday morning, the airstream may carry mold spores throughout the room before the operators realise the issue.

This situation often occurs in factories that:

- Operate 1-2 shifts/day and shut off HVAC after production

- Have no “low‑air circulation” mode during downtime

- Do not install independent humidity sensors in return air ducts

For these reasons, VCR experts strongly recommend: do not completely shut down HVAC in cleanrooms, even when production is paused. Running a low‑flow circulation mode (30‑40% airflow) is sufficient to prevent moisture accumulation and mold formation.

3.3. HEPA filter past its service life or not replaced on schedule

A HEPA filter typically has a life‑span of around 12-18 months depending on ambient conditions. However, many factories extend usage to 24 months or more to save replacement costs-unfortunately without recognising the hidden risks.

When a filter operates beyond its optimal period, dust and organic particulates (proteins, starch, oils, cellulose…) accumulate heavily on the surface. This accumulation becomes a “food source” for mold. Combined with ambient humidity, this dust layer retains water and forms a biofilm, enabling robust mold growth directly on the filter surface.

Common signs include:

- A sudden increase in pressure drop (ΔP) across the filter

- Reduced airflow, altered FFU fan sound

- Filter media surface change colour, damp smell or speckled dark spots

Consequences:

- Reduced filtration efficiency → no longer meeting “≥ 99.97% @ 0.3µm” specification

- Increased pressure drop → HVAC works harder, higher energy cost

- Microbial proliferation risk → reverse contamination

Recommendations:

- Check pressure drop monthly, replace filter when ΔP exceeds 2‑3× initial value

- Implement scheduled automatic replacement via QR code or maintenance software

3.4. Cleaning procedures not according to GMP standard

A frequently overlooked yet widespread cause: improper cleaning. In many production sites, cleaning staff wipe HEPA boxes or clean ceilings with wet cloths, water or high‑strength detergents. Some even spray disinfectant mist directly below air supply outlets.

Result? Moisture or chemicals penetrate the gasket, seep into the adhesive of the HEPA filter. If the adhesive cannot withstand moisture, it cracks or detaches, creating gaps for microbial ingress. After several weeks, dark spots appear on the adhesive and filter edges, then spread across the surface.

Another error: cleaning the clean ceiling area simultaneously while the area is in operation, causing moisture from the cleaning solution to contact the active HEPA. According to GMP Annex 1 standards, the air‑supply zone must be cleaned only by dry methods, no sprays or solutions that generate mist, and disinfectant concentrations must remain low (e.g., IPA 70% or a neutral solution).

Solutions:

- Apply a “Dry Cleaning for Cleanroom Ceiling” procedure

- Avoid wiping or spraying within active supply zones

- Retrain cleaning staff and QA personnel to eliminate recurring procedural faults

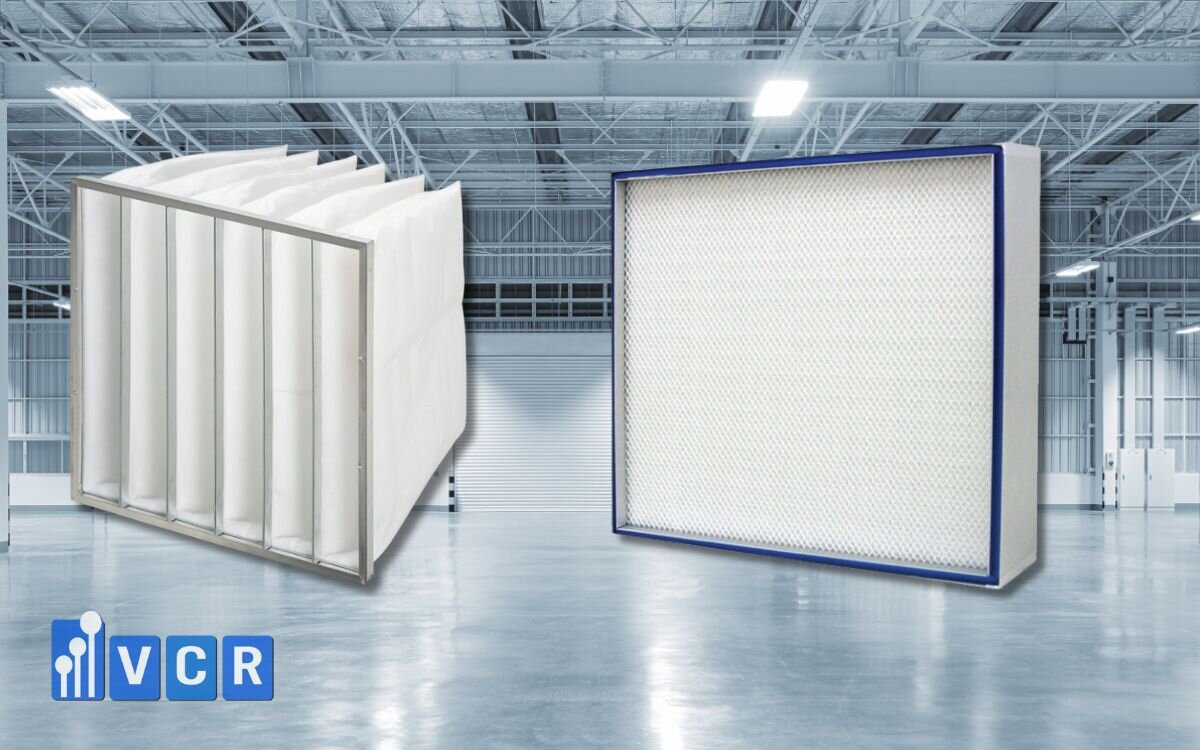

3.5. Inappropriate materials or gaskets

Not all HEPA filters are built equally. In many factories, to save costs, users choose inexpensive frames (painted steel or extruded aluminium), standard PU adhesive and cheap gaskets. Such materials absorb moisture, rust easily and deform over time.

Once a PU gasket absorbs water, the contact surface between filter and frame becomes a fixed moisture‑accumulating zone-mold may grow within 1-2 weeks. Worse, if the frame paint peels and rust appears, it creates a chemical environment favourable for mold growth (iron ions help mold enzyme systems).

Conversely, HEPA frames made of SUS 304 stainless steel or anodised aluminium, combined with EPDM moisture‑resistant gaskets and inorganic heat‑resistant adhesive, can nearly eliminate moisture absorption and mold risk.

Technical recommendations:

- Use SUS 304 stainless steel frames in humid or steam‑rich environments (weighing rooms, filling rooms)

- Prioritise EPDM double‑layer gaskets instead of standard PU

- When acquiring filters, request CO‑CQ specifying materials and RH tolerance ≥ 95%

3.6. High microbiological load environment

Finally, even if humidity and materials are within standards, the production environment itself may drive mold formation. High‑risk areas include:

- Weighing, filling, packaging rooms in pharmaceuticals

- Food or cosmetic production areas handling proteins or oils

- Microbiology labs, QC zones… which naturally have higher microbial density

When a HEPA filter’s efficiency declines (due to overload or high ΔP), spores from the air or materials may pass through and attach to the “clean” side of the filter-where moisture and nutrients support growth. Particularly in rooms with many operators, CO₂ and moisture from exhalation raise local RH, further promoting mold.

Therefore, maintaining positive pressure and unidirectional airflow (laminar flow) is crucial to prevent microbial migration backwards.

Suggested solutions:

- Install pre‑ and medium filters (Pre + Medium) upstream of HEPA to reduce organic load

- Periodically monitor microbial levels at HEPA discharge grids-if > 1 CFU/plate/4 h, inspect the system

- Strengthen air filtration in weighing/packaging zones with dedicated FFUs

4. Consequences when a HEPA filter develops mold

When a HEPA filter is mold‑infested, the issue is not just “unsightly” or reduced equipment lifespan. It is an indicator that the entire clean‑air system is losing control. A moldy filter can continuously become a source of microbial release, disrupt pressure balance, misclassify clean‑room grade, cause cross‑contamination risk and directly impact GMP assessments. Below are four major consequences commonly faced by factories.

4.1. Loss of filtration effectiveness and reduced clean‑room grade

When the glass‑fiber media of a HEPA filter is covered by mold:

- Fibers stick together, reducing surface area contact with airflow

- Mold spores and organic dust form a biofilm, hindering airflow

Direct consequences:

- Pressure differential (ΔP) increases significantly → airflow falls

- Airflow becomes turbulent rather than laminar

- Air no longer “sweeps” particles from the production zone as designed

In this state, the clean‑room classification can quickly degrade:

ISO 5 may drop to ISO 7-8 equivalence; particle counts ≥ 0.5 µm can increase 10-50×. Once airflow is disrupted, dust and microbes can re‑suspend easily, contaminating areas previously considered high‑grade. Even worse, microbes may be emitted backwards into the room from the filter side when the AHU or FFU is operating strongly. In pharmaceutical or microbiology environments, this is a serious sterility risk-mold spores can survive and adhere to surfaces.

4.2. Risk of cross‑contamination of products

In pharmaceutical, cosmetic and food industries, cross‑contamination is a taboo. A moldy HEPA filter doesn’t just hold microbes-it can release enzymes, mycotoxins and spores into the environment. These ultrafine particles, if introduced into weighing, filling or packaging operations, can compromise entire lots. Example:

- In a pharmaceutical plant, mold Aspergillus on a HEPA surface contaminated a capsule line → recall of 200,000 capsules

- In a food facility, a mold‑infested HEPA triggered microbial counts above HACCP thresholds → three days of suspended production for re‑validation

Under GMP requirements: when mold is found in an air‑supply area:

- Production must stop immediately

- Full clean‑room re‑validation is required (pressure test, smoke test, microbial test, DOP test)

This not only disrupts production but incurs major financial loss from destroyed batches, lost time, and re‑validation.

4.3. HVAC system impact and energy cost

An often overlooked but costly consequence: mold on HEPA filters increases load on the entire HVAC system. When the filter is clogged, the supply fan in the AHU or FFU must spin faster to maintain pressure and airflow. This leads to:

- 10-30% higher energy consumption (especially in 24/7 systems)

- Shortened motor/ bearing lifespan, increased vibration, noise and risk of failure

- Pressure imbalance between clean zones: zones intended to be positive become under‑pressure relative to adjacent zones, increasing the risk of dirty air being drawn in

Over time, operating under these conditions destabilises temperature/humidity control and wastes energy while failing to maintain cleanliness. In real terms, added electricity and HVAC maintenance cost over a year may amount to 3-4× the cost of replacing the HEPA filter. Delaying filter replacement “to save” often turns out to be an expensive mistake.

4.4. Validation failures and factory reputation risk

Mold in a HEPA filter is a serious deviation from GMP, ISO 14644 and HACCP standards. During audits, this issue is treated as a “Major” or “Critical Deviation” by regulatory bodies (e.g., Ministry of Health, WHO GMP) or OEM customers. The factory may face:

- Temporary production suspension until remediation is complete

- Mandatory re‑validation of the entire affected zone (pressure test, smoke test, microbial count, DOP test)

- Loss of GMP/ISO certification while an assessment is pending

Beyond technical costs, reputation and customer trust are severely impacted. Once a “mold in the clean zone” report surfaces, export partners or OEM customers may halt contracts, directly affecting revenue and credibility. Example:

At a cosmetic plant certified under ASEAN GMP, the 2024 audit found Cladosporium on HEPA box surfaces in the filling zone. Production was halted for 15 days, full disinfection performed, filters replaced, PAO testing and re‑validation done. The cost of remediation and production loss exceeded VND 200 million, not including reputational damage with Korean OEM client.

See more: How to test air flow in food factory

5. Standard procedure when discovering a mould‑infested HEPA filter

When a HEPA filter is found to be mould‑infested, the most important step is not simply wiping or “temporary cleaning”, but triggering a GMP‑compliant emergency procedure to protect the system and prevent contamination from spreading. In a cleanroom environment, even a few hours’ delay may allow mould spores to spread via the airflow and affect dozens of other areas.

Below are the five recommended steps by VCR - intended for operation engineers, QA/QC teams and maintenance staff when facing a mould issue in a HEPA filter.

5.1. Stop use and isolate the area

As soon as mould is observed on the surface of the HEPA filter or inside the HEPA box, stop all operations in the affected area. Do not continue fan or HVAC operation because this may spread spores to other rooms.

Actions to take:

- Shut off air supply for the area by locking duct dampers or turning off FFUs.

- Isolate the zone: close doors and display a sign “Do Not Enter - Contaminated Area”.

- Record current parameters: differential pressure between rooms, temperature, humidity, HVAC status.

- Conduct a quick smoke‑test if needed to verify airflow direction and determine contamination extent.

5.2. Root cause analysis (RCA)

Once the area is isolated, the QA/QC and engineering team must perform a root cause analysis. This step is essential not only for remediation but also for preventing recurrence.

Suggested process:

- Check RH and temperature at time of detection; if RH > 60% then inspect RH control components of AHU or dehumidifier.

- Review filter material: frame type (steel, aluminium, SUS304), sealant type (organic/inorganic), gasket type.

- Review recent cleaning procedures: Was wet cleaning or misting done near the HEPA box or supply outlet?

- Review HVAC operating logs: Was the system shut down overnight or during weekends?

- Document status with photos/videos for internal report.

Then prepare a Non‑Conformance Report (NCR) and a CAPA plan (Corrective & Preventive Actions) listing:

- Scope of impact

- Involved areas

- Direct and indirect causes

- Remedial and preventive actions

5.3. Remove and discard the mouldy HEPA filter

Never attempt to “wash” or re‑use a mouldy HEPA filter. HEPA media is porous and cannot be fully sterilised; mould spores can remain embedded deep in the media.

Steps:

- Don full PPE: gloves, N95 mask, goggles, anti‑static gown.

- Encase the HEPA filter in thick polyethylene or sealed bag before removing from HEPA box to avoid dispersing mould dust.

- Seal and label the bag “Bio‑contaminated - Do Not Reuse”.

- Transport to a designated hazardous waste area (Biohazard disposal).

- In some cases, disinfect the outer bag surface with ClO₂ or 70% alcohol before removing from the clean zone.

5.4. Clean & disinfect the system

After the mouldy filter is removed, perform a full clean and disinfection of the clean‑air system - including the HEPA box, ductwork, AHU, and surrounding area.

Steps:

- Mechanical cleaning: use dry wipes or soft brushes on the frame; do not use water. Check for rust or moisture accumulation.

- Chemical disinfection: apply 70% isopropyl alcohol (IPA), chlorine dioxide (ClO₂) or a specialist antifungal solution. Spray or wipe uniformly; avoid pooling of liquid.

- Duct & AHU cleaning: inspect cooling coil, condensate pan and drain lines; remove moisture accumulation. Use dry compressed air or robot cleaning for ductwork if needed. Disinfect inside AHU with low‑level ClO₂ (<0.1 ppm).

5.5. Replace and re‑qualify

Once cleaning is complete, replace with a new HEPA filter and execute full validation (re‑validation) under GMP procedures.

Steps:

- Replace HEPA filter: ensure full CO‑CQ, specify model, performance (≥99.97%@0.3µm), frame material and gasket. Prefer SUS 304 frame, inorganic sealant, EPDM gasket for high‑RH environments. Log serial number and installation date.

- Performance tests (as per ISO 14644 and GMP):

- Measure differential pressure before and after filter: verify design pressure drop (e.g., 100-250 Pa depending on system).

- Conduct smoke test to verify airflow direction and leakage.

- Perform DOP/PAO or aerosol challenge test: confirm ≥99.97%@0.3µm.

- Run microbial and particle monitoring after 12-24 h operation.

- Document IQ/OQ/PQ:

- IQ (Installation Qualification): confirm correct installation and model.

- OQ (Operational Qualification): verify filter performance meets design parameters.

- PQ (Performance Qualification): confirm cleanroom grade is achieved in actual operation.

6. Preventive measures for mould in the air filtration system

A cleanroom is only truly “clean” when it is maintained in a stable condition over time. Preventing mould in HEPA filters is not merely a technical response - it’s a holistic strategy of cleanroom management, covering environmental control, material specification, maintenance procedures and staff training. Below are the five most effective preventive actions recommended by VCR and applied in numerous GMP pharmaceutical, food and cosmetic factories nationwide.

6.1. Control of humidity and temperature

Humidity is the “food” of mould. Therefore, the first principle is to maintain relative humidity (RH) at 40-55% and temperature at 20-24°C throughout the clean‑air system. When RH exceeds ~65%, water vapour begins to condense on glass‑fibre media, providing conditions for mould spore growth within 24-48 hours.

Technical measures:

- Install RH and temperature sensors at both supply and return air points to monitor differential.

- Set automatic alerts when RH exceeds ~60% so engineers can respond early.

- Clean and maintain cooling coils, condensate pans in AHUs every 3-6 months to prevent water accumulation.

- Ensure ductwork and AHU housing insulation meets standard to prevent condensation on metal surfaces.

6.2. Maintenance and scheduled filter replacement

A cleanroom system only remains stable with a clear, traceable filter maintenance schedule. Many HEPA mould incidents originate from filters being “overused” or differential pressure checks being neglected.

Recommendations:

- Establish a scheduled filter replacement plan via maintenance software or QR‑code tags on each HEPA box to track installation date, ΔP, maintenance history.

- Measure ΔP (pressure drop) across filters monthly and record in logbook. If ΔP rises to 2‑3× initial value, replace filter immediately.

- Perform visual inspections: filter media that changes colour, shows moisture spots or smells damp should be replaced earlier.

- Replace pre‑filters and medium filters on schedule because they act as the “shield” protecting the HEPA from organic dust load.

Maintenance isn’t just periodic - it’s proactive management of microbial load and energy efficiency. A correctly scheduled filter helps reduce HVAC load, save energy and maintain a stable airflow.

6.3. Operate low‑flow circulation mode during non‑production times

One of the main causes of HEPA mould is shutting down the HVAC completely when the plant is in off‑hours. When air doesn’t circulate, humidity builds up in technical ceilings, ductwork and HEPA boxes - creating perfect conditions for mould growth.

Solution:

- Configure HVAC system with a “Low Air Circulation Mode”, maintaining about 30-40% airflow even when production is paused.

- Use timers or BMS to automatically activate this low‑flow mode overnight, on weekends, or during holidays.

- Ensure room positive pressure is still maintained (min. +10-15 Pa) relative to adjacent zones

Benefits:

- Prevents condensation and mould formation.

- Maintains stable cleanliness, reducing the time required to “ramp up” when production restarts.

Especially in pharmaceutical, food or microbiological factories running shifts, this mode is essential to maintain sterile environment continuity.

6.4. Use moisture‑resistant and mould‑resistant materials

Selecting the correct HEPA filter from the start is the first step in long‑term mould prevention. Cheap filters often use painted steel or ordinary aluminium frames, organic PU adhesives and basic gaskets - all of which absorb moisture and degrade quickly.

VCR recommends:

- HEPA frames made of SUS 304 stainless steel or anodised aluminium - abrasion‑resistant, moisture‑proof, easy to clean.

- Inorganic sealant adhesives rather than organic PU - improved durability, no microbial substrate.

- Double‑layer EPDM or silicone gaskets for absolute airtightness, water/microbe resistance.

- Filters certified to EN 1822 (H13-H14) and able to operate in high humidity (>95% RH).

While initial cost may be ~10-15% higher, the long‑term savings in replacement and re‑validation costs far outweigh the investment.

6.5. Train cleaning staff and QA teams

Human error is the often “hidden root cause” in most cleanroom incidents. Hence, training and awareness are indispensable.

Training content should include:

- Clear distinction between “cleaning zone” and “dry area” - only dry cleaning methods near supply air zones.

- Correct chemical use: use 70% IPA or low‑concentration hydrogen peroxide; avoid high‑concentration chlorine solutions, water‑based scrubbing or spray‑mist near supply outlets.

- Proper cleaning of ceilings and HEPA boxes: no direct spray of solution onto supply grilles, no cleaning while HVAC is operating.

- QA oversight: conduct surface microbial checks on HEPA frames, ceiling and filter housings once or twice monthly.

- Hold quarterly refresher training for cleaning staff, engineering and QA/QC personnel - update on GMP standards, mould remediation procedures and root‑cause practices.

7. Frequently Asked Questions

1. What are the signs that a HEPA filter is mouldy?

Common indicators include:

- Presence of black, green, or light grey spots on the filter surface.

- Slight musty smell when the HVAC or FFU system is turned on.

- Sudden increase in differential pressure (ΔP), with decreased airflow.

- In some cases, mould dust can be observed at the air grille or on the ceiling surface near the HEPA box.

If any of these signs appear, immediately stop using the area and conduct an inspection to prevent mould spores from spreading through the entire system.

2. Can a mouldy HEPA filter be cleaned and reused?

No. HEPA filters are designed for single-use and to trap particles and microorganisms at a microscopic level.

Once mould develops, spores penetrate deep into the glass fibre layers and cannot be fully removed by washing, wiping, or disinfection. Attempting to reuse it will reduce filtration efficiency and poses a risk of microbial cross-contamination.

The only solution: Replace with a new filter and follow GMP-standard procedures for cleaning, disinfection, and re-validation.

3. How often should HEPA filters be inspected?

According to VCR recommendations and standards like ISO 14644 / GMP Annex 1:

- Check differential pressure and visual condition monthly.

- Perform DOP/PAO testing every 6-12 months.

- Replace filters every 12-18 months, or earlier if:

- ΔP increases 2-3 times the initial value.

- Filter surface changes color, shows moisture signs, or develops mould.

- Airflow drops or becomes uneven.

Regular inspections help detect mould risks early and maintain energy efficiency and stable room pressure.

4. What is the main cause of mould in HEPA filters?

Based on data from VCR Cleanroom Service technicians, over 70% of HEPA mould incidents are caused by high humidity and HVAC systems being shut down for long periods.

Specifically:

- RH > 65% for several hours leads to moisture on the filter fibres → ideal conditions for mould growth.

- When HVAC is off, air becomes stagnant → moisture builds up → mould develops.

Other contributing factors include overdue filter replacement, incorrect cleaning practices, or poor-quality materials.

Effective prevention: Maintain RH between 40-55%, ensure HVAC operates continuously (including in low-circulation mode) 24/7.

5. Are VCR HEPA filters resistant to mould?

Yes. VCR’s HEPA Box and HEPA filters are specially engineered for high-humidity environments and comply with GMP/ISO 14644 standards, featuring:

- SUS304 stainless steel frames: rustproof and moisture-resistant.

- High-grade inorganic sealants: heat and humidity-resistant, non-biodegradable, and not a substrate for microbes.

- Double-layer EPDM gaskets: ensure airtight sealing, water resistance, and microbial barrier.

- Filtration efficiency ≥99.97%@0.3µm - suitable for ISO 5-8 cleanroom grades.

VCR also offers full-service packages for HEPA inspection, maintenance, and replacement - helping factories maintain peak filter performance and prevent future mould outbreaks.

Contact us today:

Hotline: 090.123.9008

Email: [email protected]

Website: https://vietnamcleanroom.com/

Diep VCR