Pass Box: Definition, Specifications & Working Principle

Pass box is an indispensable unit in cleanroom. In this article, VCR will introduce you pass box definition, specifications, and working principle. 1. Pass box definition Pass box is a kind of facility used for transferring goods between inside and

Pass box is an indispensable unit in cleanroom. In this article, VCR will introduce you pass box definition, specifications, and working principle. Let's find out!

If you want to order pass box for cleanroom in Viet Nam, please contact VCR via hotline +84 90 123 7008.

1. Pass box definition

Pass box is a kind of facility used for transferring goods between inside and outside of cleanroom. It is normally located on partition walls of cleanroom.

It can prevent any disturbance of airflow and air pressure in clean room, which can be caused by the door opening for goods transferring. Moreover, it can reduce the time from operators moving in and out, to prevent any dust coming from the out regions.

Pass box for clean room is equipped with UV lamp which is used for bacteria control. Pass box is provided with two interlocked doors, when a door is open, the other door is forced to close, in this way it prevents direct contact between the connected areas.

2. Pass box classification

According to the purpose, the pass box for clean room is divided into two types: static pass box and dynamic (self-cleaning) pass box

-

Static pass box

Static pass box is normally used to transfer materials and goods between cleanrooms of the same levels.

Static pass box is equipped with UV light and an interlock system. There are 2 types of static pass box: mechanical interlock static pass box and electronic interlock static pass box

-

Dynamic pass box

Dynamic pass box is normally used to transfer materials and goods between cleanrooms of different levels or between cleanroom and non-cleanroom.

Besides UV light and an interlock system, dynamic pass box is equipped with a suction HEPA filter of around 0.3 microns. The dynamic pass box also has a differential pressure gauge ranging from 0 to 250 pa. It is also equipped with a motor blower for blowing out dust particles.

Read more: 9 things you should know about dynamic pass box

3. Pass box structure

In general, a pass box includes 4 main parts: Casing, body, door, and lock.

-

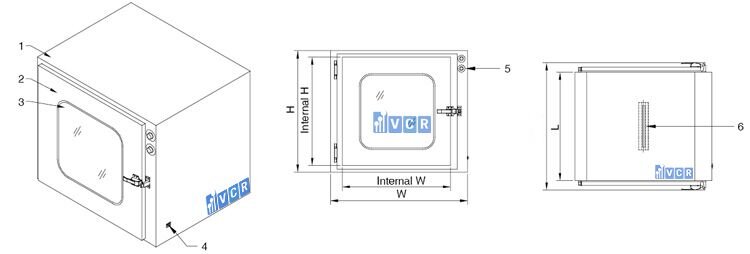

Static pass box structure

A static pass box is composed of: (1) Casing, (2) Door, (3) Tempered glass, (4) Power, (5) Control panel, (6) UV light, and mechanical/electronic interlock system

Body: The body of the box consists of the outer casing and the inner chamber. The inner chamber is made of 304 stainless steel, while the outer casing can be made of materials such as 304 stainless steel, 201 stainless steel, powder-coated steel, etc.

When buying a pass box, we need to consider the external size and the internal size of the pass box body.

Doors: Two doors (one on each side) with tempered glass windows sealed by durable feather edge rubber prevents airborne particles contamination. Besides, each door has door handle. The door handles are different according to the types of interlock system pass box uses.

Pass box hinges made of SUS 304 stainless steel are durable and easy to clean

Interlock system: This is an important part of every pass box, ensuring two doors don't open at the same time. This prevents the risk of cross-contamination in clean rooms. Interlock system has two types: mechanical interlock system and electronic interlock system

UV light: UV light are designed inside pass box for disinfection of transferred objects before entering the cleanroom.

-

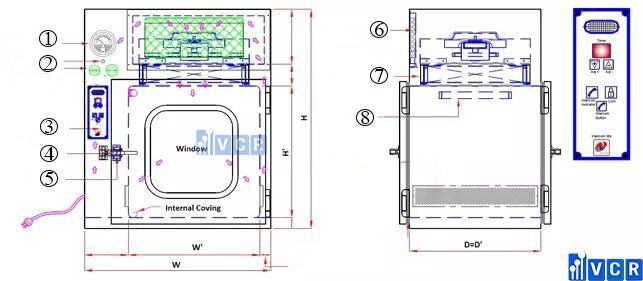

Dynamic pass box structure

A dynamic pass box is composed of: (1) Differential pressure gauge; (2) DOP/PAO test port; (3) Control display; (4) Door handle; (5) Interlock system; (6) Pre-filter; (7) Hepa filter; (8) UV light.

Fan: It sucks the air and blows it through HEPA filter. The clean air will go into the chamber to sterilize the objects

Pre-filter: G4 filter is used to remove large particles

HEPA filter: H13 or H14 filter with filtration efficiency up to 99.995% is widely used in dynamic pass box

DOP/PAO test port: Provision of DOP/PAO Test Port in dynamic pass box is available for HEPA Filter leak test and particle count.

Differential pressure gauge: It is used in dynamic passbox to check the differential pressure across HEPA filter

4. Pass box working principle

-

Static pass box working principle

+ Mechanical interlock static pass box

The interlock is in mechanical form. When one door is opened, the other door cannot be opened. One door must be closed before the other door can be opened.

+ Electronic interlock static pass box

The electronic interlock use integrated circuits, electromagnetic locks, control panels, and indicator light.

When one door is opened and the indicator light is on, the indicator light on the other side does not light up, indicating that the door cannot be opened at the same time. When the door is closed, the indicator light on the other side will light up, indicating that the other door can be opened.

+ When the material is put inside pass box and the door is closed, UV light will be turned on within 15 minutes to kill the bacteria. Then the material will be taken out.

- Dynamic pass box working principle

Dynamic pass box is a self-cleaning pass box. The air is sucked by a centrifugal fan then passed through HEPA filter. After the pressure is equalized, the filtered air enters the working zone at a uniform air velocity, forming a clean working environment.

The air outlet surface can also be replaced with a nozzle, which increases the air velocity to meet the requirements of blowing dust on the material surface.

5. Pass box specifications and dimensions

-

Static pass box specifications and dimensions

| Model | VCR500SP | VCR600SP | VCR700SP | VCR800SP |

|

External size (L×D×H)mm |

620×560×580 | 720×660×680 | 820×860×780 | 920×860×880 |

|

Working size (L×D×H)mm |

500×500×500 | 600×600×600 | 700×700×700 | 800×800×800 |

| Casing material | Powder-coated steel / Stainless steel (SUS304) | |||

| Body material | Stainless steel (SUS304) | |||

| Interlock | Mechanical/electronic interlock system | |||

| Power | 220V/50Hz | 220V/50Hz | 220V/50Hz | 220V/50Hz |

-

Dynamic pass box specifications and dimensions

| Model | VCR500DP | VCR600DP | VCR700DP | VCR800DP |

|

External size (L×D×H) mm |

670×580×1000 | 770×680×1100 | 870×780×1200 | 970×880×1300 |

|

Working size (L×D×H) mm |

500×500×500 | 600×600×600 | 700×700×700 | 800×800×800 |

| Casing material | Stainless steel (SUS304) | |||

| Body material | Stainless steel (SUS304) | |||

| Interlock | Electronic interlock system | |||

| Power | 220V/50Hz | 220V/50Hz | 220V/50Hz | 220V/50Hz |

6. Precautions on using pass box

- First, we should check whether the interlock system works properly. If not, contact the manufacturer/supplier or professionals to repair the pass box.

- The service life of UV light is 4000 hours. Be aware of the working performance of UV light. If UV light is out of order, it should be replaced instantly.

- When it comes to dynamic pass box, filter maintenance is necessary. Pre-filter (like G4) needs replacing every 6 months. HEPA filter needs replacing every 6-12 months.

- Check the differential pressure gauge on dynamic pass box regularly to monitor the filter integrity.

- Any maintenance activities must ensure the cleanliness of cleanroom

7. Pass box applications

Pass box is an indispensable unit in cleanroom. Pass box is applied in any industry that needs cleanrooms, such as pharmaceutical cleanrooms, electronic cleanrooms, food processing cleanrooms, hospital cleanrooms, laboratories, etc.

8. Pass box supplier in Viet Nam

Vietnam Cleanroom Equipment (VCR) is one of the most reliable pass box supplier in Viet Nam for cleanroom contractors.

We provide high-quality products with competitive prices and large quantities nationwide.

At Vietnam Cleanroom Equipment, our team knows how to help you find the right pass box for your needs. Get a quote for pass box price and know exactly what to expect – contact us today via hotline +84 90 123 7008 (Whatsapp)