7 steps to building an effective quality control plan

What is a quality control plan? Why is it considered the most important element of a business? Find out details with VCR here.

Every year, hundreds of businesses are established, intensifying competition for market share. This overarching trend makes quality control planning one of the decisive factors for a business's success. Proper implementation of the plan will help ensure the quality of the output products, contributing to the establishment of a sustainable reputation with consumers. The following article by VCR will provide readers with the most comprehensive overview and effective strategies for building a quality control plan.

Overview of Quality Control Plan

Before delving into how to establish a product quality control plan, VCR will provide readers with a general overview to deepen their understanding of this concept.

What is quality control plan?

The Quality Control Plan is a type of document that outlines a series of methods and plans with the aim of controlling the quality of input. Through this, businesses can meet the essential requirements at the output that customers aim for.

From a monitoring and management perspective, the Control Plan assists in establishing clear standard processes while providing an objective evaluation of product quality. Typically, the control plan is presented in the form of a sheet or list.

In particular, establishing a Control Plan helps maintain the consistency and stability of product quality even in the face of personnel changes. However, it is crucial to ensure the accuracy and regular updating of the data in this document.

Types of Effective Quality Control Plans

In addition to understanding what a product Quality Control Plan is, determining and classifying the Control Plan is equally important. Currently, the Control Plan is divided into three specific types corresponding to three production stages.

- Prototype Control Plan: This plan aims to present and control the characteristics of the product, such as dimensions, weight, etc. Subsequently, it involves applying tests for durability and performance.

- Test Run Control Plan: After completing the prototype plan, if the product has not achieved stability, the test run is initiated. This stage involves similar controls but is applied to approved samples and in larger quantities.

- Mass Production Control Plan: Involves controlling factors such as features, processes, inspections, and measurements in the production process.

Why do you need quality control plan?

Many experts believe that a Quality Control Plan is a crucial step that leads businesses to success, offering significant benefits:

- Elimination of Risks: By swiftly addressing emerging issues before they become severe, a Quality Control Plan helps eliminate the risks of resource and manpower wastage during the production process.

- Rapid Identification of Core Workforce: The plan facilitates the quick identification of key labor sources and the establishment of effective control and monitoring mechanisms.

- Focus on Key Product Characteristics: By concentrating on the essential attributes of the product highly valued by customers, businesses can meet demand and create a positive impression with consumers.

- Optimization of Production Processes: The Quality Control Plan optimizes production processes, allowing the creation of high-quality products at the lowest possible cost.

- Enhanced Profitability: Improved performance leads to higher profits, establishing a brand position in the eyes of consumers through superior quality.

- For some manufacturing sectors, adherence to quality standards set by the law is mandatory. Therefore, Quality Control Plans also contribute to helping businesses ensure strict compliance with legal requirements.

6 important elements of a quality control plan

To establish an effective and quality control plan, the following 6 important factors certainly cannot be overlooked:

- Objectives and Quality Standards: In the process of constructing a plan, it is essential to clearly define the quality objectives that the product needs to achieve. Simultaneously, establish specific regulations to ensure the final product meets expectations.

- Quality Control Procedures: Identify methods that yield optimal efficiency and describe the procedures, methods, and tests to ensure quality meets standards. It's crucial that all aspects are consistent and provide high effectiveness.

- Responsibilities and Roles: Prioritize clearly defining the roles and responsibilities of each participant in the project.

- Tools and Documentation: List in detail the tools, equipment, and documents related to the quality control process. This typically includes machinery, measuring tools, procedural documents, and test samples.

- Handling Quality Violations: Establish a procedure for handling quality violations when they occur. This includes recording, classification, reporting, and implementing corrective actions as per regulations.

- Evaluation and Improvement: Conduct quality evaluation activities to ensure performance and efficiency in the control process. The plan should encompass improvement activities with the aim of enhancing quality and services.

Process of developing a quality control plan

Building a Quality Control Plan in 7 Simple Steps:

Step 1: Identify the quality requirements of the product and service based on information gathered from customers, industry standards, and relevant stakeholders.

Step 2: Engage with customers, record their desired quality outputs, and understand their processing capabilities.

Step 3: Determine necessary processes such as control steps, inspections, quality evaluations, etc., to meet the quality standards as per customer requirements.

Step 4: Validate standards and metrics for measuring product quality. Always ensure these parameters provide the most objective assessments. Additionally, familiarize yourself with the tools, equipment, and methods needed during the control process.

Step 5: Train and manage the workforce to execute the control methods and gather evaluation metrics. Establish standard inspection steps in each stage of the process. Validate the system's measurement capabilities in practical applications.

Step 6: Clearly define the responsibilities of each employee in the execution process. Establish a data collection system from the inspection process. Build a reporting, monitoring, and improvement team. Plan for contingencies and reactions to conditions beyond control.

Step 7: Evaluate the performance of the control plan and propose improvement plans to enhance efficiency.

Sampling plan in Quality Control

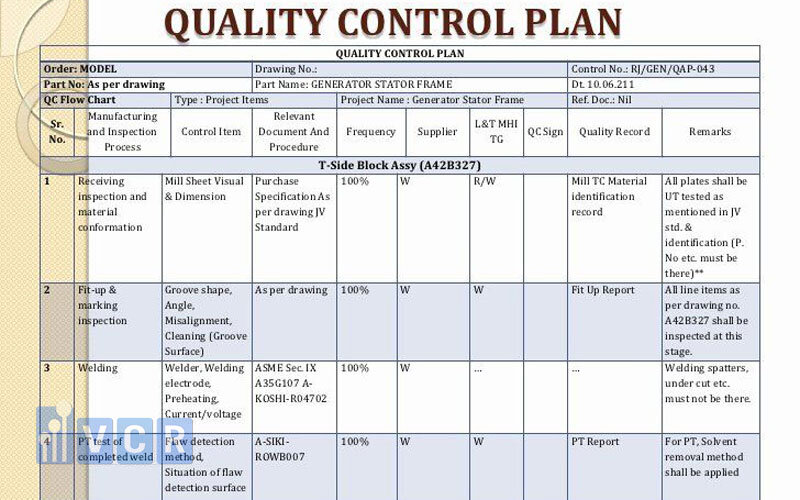

In a basic Quality Control Plan template, columns are used to organize comprehensive information swiftly addressing quality issues that exceed established standards. The information in each section of the Control Plan template typically includes:

- Basic Information: This includes the project or product name, along with details about the author, initiation date, and effective date.

- Brief Description of Quality Control Objectives: This involves specifying the applicable standards and expected outcomes.

- Information on Quality Control Methods, Tools, and Testing Equipment: Details on the methods employed for quality control, as well as the tools and testing equipment utilized.

- Schedule and Scope of Inspections: This outlines the timing and extent of inspections, along with data collection and processing methods.

- Assignment of Responsibilities and Role Descriptions: Clearly defines the responsibilities of each individual involved in the process.

- Performance Evaluation Method and Improvement Plan: Describes the method for assessing performance and outlines improvement plans based on results.

- Approver and Approval Date: Specifies the person responsible for approval and the date on which the plan becomes effective.

In the above article, VCR's cleanroom equipment has provided detailed information to readers about the quality control plan. Through this, the importance and essential factors needed to create a comprehensive plan can be clearly seen. We sincerely hope that the insights shared here bring valuable information to you.