Requirements for clean room lighting

Clean room lights are different from lights in offices, other areas...In addition to providing light, clean room lights contribute to minimizing contamination. Therefore, there are some requirements for clean room lighting that customers should take into

Clean room lights are different from lights in offices, other areas...In addition to providing visibility, clean room lights contribute to minimizing contamination. Therefore, there are some requirements for clean room lighting that customers should take into account.

1. Foot-candle

Foot-candle is the unit of lighting luminance in the United States, which equals 1 lumen per square foot.

Lumens are used to describe the light output (luminous flux) of the source. The foot-candle level required in cleanrooms has been historically high due to precision demands or the extremely small size of the object that requires attention.

The requirements for foot candle (fc) vary throughout cleanroom facilities, from 30 fc in mechanical/electrical rooms to 100 fc or more in the cleanroom. At least 150 foot-candles are needed in some cleanroom applications that involve food inspection and grading.

Revision B of Federal Standard 209 (now 209E) originally contained a requirement for 100 fc in main cleanroom areas. In fact, 100 fc has been considered harmful to eye comfort levels in cleanrooms. Moreover, it can be difficult to obtain 100 fc in Class 10 and lower cleanrooms, since most of the ceiling space is dedicated to air filters. The lighting levels in the 60 to 80 fc range appear to accommodate user comfort and most types of cleanrooms.

2. Types of lamps

LED and fluorescent lamps are most commonly used in cleanrooms. Fluorescent lamps are widely used in cleanroom areas due to their energy efficiency, low maintenance and long life.

Some requirements for fluorescent lamps in cleanrooms are shown below:

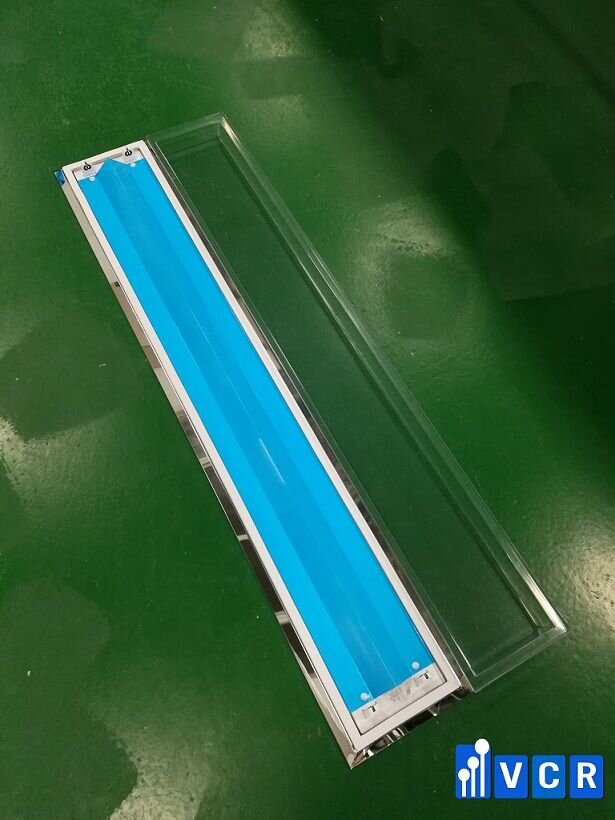

- Fluorescent lamps with cover are highly recommended for cleanrooms

- Lamps with temperatures around 3500K are often specified in cleanrooms.

- The number of light fixtures and their spacing should be reviewed to produce a uniform lighting level throughout the space.

- In some cleanrooms, lights that produce high levels of UV may be required to kill bacteria or other biological contaminants.

3. Cleanroom fixture types

The main cleanroom fixture types are recessed, surface mount and integral ceiling grid. The type of fixture chosen is typically determined by the cleanroom classification.

- Recessed light fixtures is typically used in small cleanrooms. To maintain an airtight seal, recessed light fixtures are normally supported by the ceiling grid and sit on a gasket flange or inside a gel-filled channel. Regardless of cleanroom classification, complete and reliable seals are needed for recessed fixture housings.

- Surface mount fixtures are applicable only when another configuration is not practical due to site-specific restrictions. In general, surface mount fixtures are only used in Class 10,000 or above cleanrooms. Their shape can't be made aerodynamic, and some turbulence of the airflow is unavoidable.

- Cleanroom lights built into grid channels are space-saving. This kind of ceiling system can reduce the amount of wiring required between light fixtures.

4. Clean room light fixture material

Because there are no stipulated standards for lighting for clean room classifications, it is up to the engineer or lighting designer to carefully evaluate the lighting fixture.

In general, it is recommended that light fixtures used in Class 100 to Class 1 cleanrooms should be made of powder-coated steel, anodized aluminum, or stainless steel. Stainless steel is typically required in NFS/FDA applications.

When it comes to designing cleanroom lighting system, there are various requirements. Since cleanroom processes are mission-critical, lighting fixtures must be thoroughly evaluated, specified, and installed.

Vietnam Cleanroom Equipment (VCR) specializes in providing cleanroom equipment for construction contractors. We provide high-quality products with competitive prices and large quantities nationwide. The equipment includes:

Differential pressure gauge, FFU Fan Filter Unit, Pass box, Clean room air filter, HEPA box, Clean booth, cleanroom steel door, Isolator cabinet, and other equipment

For details, please refer to Vietnam cleanroom equipment official website