What is a differential pressure gauge?

Differential pressure is one of the fundamental operating principles of cleanrooms. Differential pressure refers to the difference in air pressure from one location to another within a system. To measure differential pressure, we offer a differential

Differential pressure is one of the fundamental operating principles of cleanrooms. Differential pressure refers to the difference in air pressure from one location to another within a system. To measure differential pressure, we offer a differential pressure gauge. This article will provide the basics of differential pressure gauges. Let's find out!

1. What is a differential pressure gauge?

A differential pressure gauge (or differential pressure indicator) is a device used for measuring the difference in air pressure between two points within a system. The differential pressure gauge has 2 ports (HIGH PRESSURE and LOW PRESSURE) connected to measured points.

The differential pressure gauge can be measured in psi, pascal (pa), kilopascal (Kpa),…

How to read differential pressure gauge?

For example, if the pressure at HIGH PRESSURE port is 150 pa and the pressure at LOW PRESSURE port is 100 pa, the differential pressure is 50 pa (= 150 pa – 100 pa). This value will be displayed on the dial.

2. Differential pressure gauges applications

Differential pressure gauges are widely used to measure the pressure of fan and blower, air velocity, pressure drops across orifice plates, liquid levels with bubbler systems, and pressures in fluid amplifier or fluidic systems. It also assists in flow measurement and filter monitoring.

Read more: Differential pressure gauge for air filter

This differential pressure gauge is commonly used in chemical processing, oil refineries, gas liquefication, power plants, pharmaceutical manufacturing, food production, and industrial processes.

Differential pressure gauges are applied in cleanroom industry.

In cleanrooms, maintaining the right amount of differential pressure is critical for contamination prevention. That's a reason why differential pressure gauges are commonly used in cleanrooms.

3. Differential pressure gauge structure

A differential pressure gauge includes sensor, diaphragm, magnet, needle, high-pressure port, low-pressure port, bezel with magnets

4. How does a differential pressure gauge work?

Differential pressure gauge have two ports that are connected to the two pressure sources.

When connected to the pressure sources, the differential pressure gauge will monitor the difference in the pressure between them.

When the pressure reaches a set point, the switch will either make or break a circuit as the internal diaphragm deflects under pressure making contact. This will trigger the helix. The helix turns the needle on the gauge to indicate the pressure.

5. How many types of differential pressure gauges?

- According to sensing mechanism, there are 2 kinds of differential pressure gauges: Piston type differential pressure gauge and diaphragm type differential pressure gauge.

Piston type gauge measures the differential pressure based on the movement of a piston in a bore against a spring. This gauge can be used for liquid applications or in systems where the bypass of fluid is permissible.

Diaphragm type gauge measures the difference in pressure by using rubber diaphragm against a spring. The high pressure port and low pressure port are isolated. Diaphragm type gauges are applied in air, gas and liquid measurement.

Diaphragm type differential pressure gauge is the one mostly used in cleanrooms.

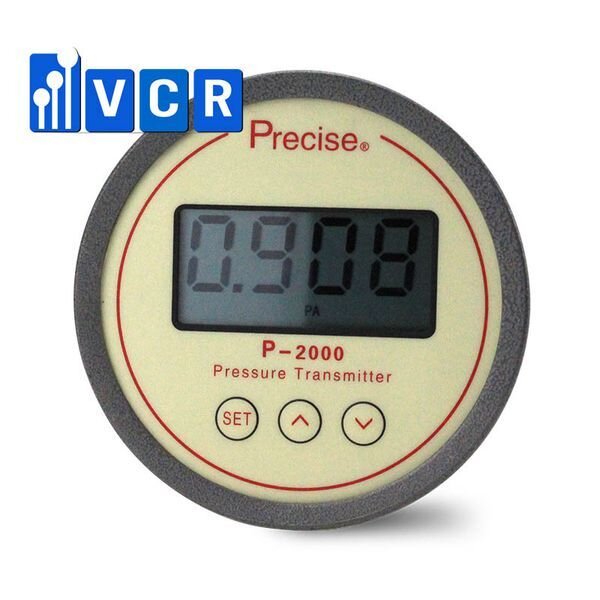

- Differential pressure gauges can be categorized into 2 types: Mechanical differential pressure gauge and digital differential pressure gauge.

6. Differential pressure gauges supplied by VCR

We provide 2 brands of differential pressure gauge, which are MAGRFHELIC and MACROSCOPIC series 2000 with various pressure ranges (-60-60pa, 0-60pa, 0-250pa, 0-500pa, 0-750pa,...)

VCR also provides differential pressure gauge accessories.

Why choose VCR differential pressure gauges?

- Accurate measurement

- Various pressure ranges

- Replacement for goods having faults from manufactures

- Fast delivery

- Reasonable price

- Professional service

We provide Differential Pressure Gauges Series 2000 for cleanrooms throughout the provinces and cities:

North: Lao Cai, Yen Bai, Dien Bien, Hoa Binh, Lai Chau, Son La. Ha Giang, Cao Bang, Bac Kan, Lang Son, Tuyen Quang, Thai Nguyen, Phu Tho, Bac Giang, Quang Ninh. Bac Ninh, Ha Nam, Hanoi, Hai Duong, Hai Phong, Hung Yen, Nam Dinh, Ninh Binh, Thai Binh, Vinh Phuc.

Central Region: Thanh Hoa, Nghe An, Ha Tinh, Quang Binh, Quang Tri and Thua Thien-Hue. City. Da Nang, Quang Nam, Quang Ngai, Binh Dinh, Phu Yen, Khanh Hoa, Ninh Thuan and Binh Thuan. Kon Tum, Gia Lai, Dak Lak, Dak Nong and Lam Dong.

South: Ho Chi Minh City, Dong Nai, Ba Ria-Vung Tau, Binh Duong, Binh Phuoc, Tay Ninh, Ho Chi Minh City. Can Tho, Long An, Tien Giang, Ben Tre, Vinh Long, Tra Vinh, Dong Thap, An Giang, Kien Giang, Hau Giang, Soc Trang, Bac Lieu and Ca Mau

Vietnam Cleanroom Equipment (VCR) specializes in providing cleanroom equipment for construction contractors. We provide high-quality products with competitive prices and large quantities nationwide. The equipment includes:

Differential pressure gauge, FFU Fan Filter Unit, Pass box, Clean room air filter, HEPA box, Clean booth, cleanroom steel door, Isolator cabinet, and other equipment