What is PGS? How to meet PGS standards?

PGS, or Participatory Guarantee System, is a system ensuring the participation and contributions of organizations and farmers in the organic production and supply process.

In this article, let's explore what is PGS and the PGS standards in Vietnam together with Vietnam Cleanroom Equipment!

What is PGS?

What is PGS?

PGS - Participatory Guarantee System means a system ensuring participation.

It is a assurance system based on direct involvement and contributions to the organic supply chain by responsible businesses, organizations, and individuals. It simultaneously encourages or requires contributions in the certification process from farmers producing and consumers.

PGS is a system that has been implemented in many countries worldwide, such as the United States, India, Peru, New Zealand...

There are two aspects that PGS focuses on:

- Direct connection between the supplier and the demand side.

- Building trust for consumers in products produced according to organic standards.

What is PGS Certification?

Built on the basis of the organic agricultural production standards 10-TCN 602-2006, PGS certification, as announced by the Ministry of Agriculture and Rural Development, will be the only certification with a domestic scope demonstrating the organic origin of the product.

PGS is a system that requires the participation of businesses and individuals directly involved in the production chain, including the following components:

- Household groups

- Production groups

- Liaison groups

- PGS coordination groups

Products with organic certification not only strengthen consumer trust and protect health but also contribute to enhancing the competitive opportunities of businesses in the market.

PGS standard in Vietnam

- Water used in organic cultivation must be clean and not polluted (according to the regulations in the safe vegetable production standard TCVN 5942-1995).

- Organic production areas must be well-isolated from pollution sources such as factories, industrial zones, construction areas, main traffic routes, etc.

- Prohibition of using all types of chemical fertilizers in organic production.

- Prohibition of using chemical pesticides.

- Prohibition of using synthetic growth stimulants.

- Spraying equipment used in conventional farming should not be used in organic farming.

- Tools used in conventional farming must be cleaned before use in organic farming.

- Farmers must maintain records of all input materials used in organic farming.

- Parallel production is not allowed: crops in organic fields must be different from those in conventional fields.

- If neighboring fields use prohibited substances in organic farming, the organic field must have a buffer zone to prevent the infiltration of chemicals from nearby fields. Organic crops must be planted at least one meter away from the buffer zone. If airborne contamination occurs, a type of plant must be grown in the buffer zone to prevent the spread of sprayed dust. The type of plant in the buffer zone must be different from the organic crops. If contamination occurs through water, there must be a embankment or drainage ditch to prevent contamination from dirty water overflowing.

- Short-term crops produced according to full organic standards from land preparation to harvest can be sold as organic products.

- Perennial crops produced according to full organic standards from the end of the previous crop to flowering and harvesting the next crop can be sold as organic products.

- Prohibition of using all input materials containing genetically modified organisms (GMOs).

- Use organic seeds and available organic planting materials. If not available, conventional planting materials can be used, but they must not be treated with chemical pesticides before planting.

- Prohibition of burning branches and straw, except for traditional slash-and-burn methods.

- Prohibition of using human waste as fertilizer.

- Animal manure brought in from outside the farm must be composted before use in organic farming.

- Prohibition of using compost made from municipal waste.

- Farmers must take measures to prevent erosion and soil salinity.

- Bags and containers for transporting and storing organic products must be new or cleaned. Bags and containers that contain prohibited substances in organic farming are not allowed.

- Prohibited plant protection products in organic farming are not allowed to be used in storage areas for organic products.

- Only inputs registered with PGS and approved by PGS can be used.

How to Meet PGS Standards?

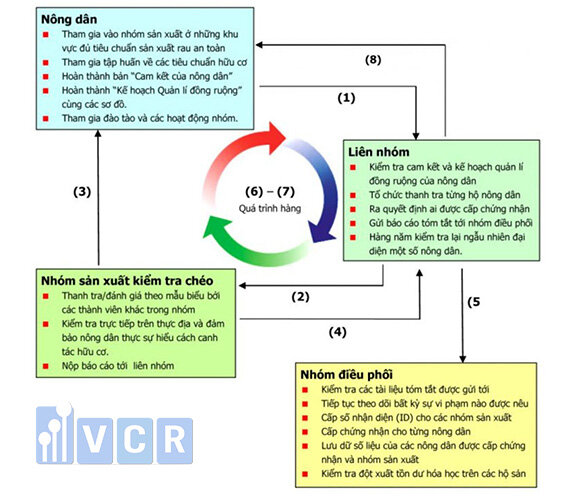

Below is a process model outlining the steps to comply with PGS standards, according to the Institute of Applied Biological Research that you can refer to:

Basic Principles of PGS

Active participation in the production group

Individuals and organizations are required to participate in training to sufficiently join the production group. Afterward, they voluntarily commit to following the standards and submit a shared field/farm management plan to the coordinating group.

Inspection of the plan

The coordinating group will conduct an inspection and provide feedback to the group for further cross-checking.

Actual Inspection

Three members of the production group will be responsible for inspecting documents, records, and areas such as cultivation, storage, processing, and housing of farmers according to regulations.

Certification Decision

Based on the inspection assessment report, the group certification council will decide whether to issue certification or not.

Issuance of PGS Certification

Once the data is updated in the system, the certification will be issued to individuals or organizations. The certification document will include the farmer's ID code and the group identification with a validity period of 1 year.

Reinspection

The production area will undergo a reinspection annually to ensure the maintenance of standards. Certification will only continue if the inspection results meet the standards according to the above process.

Additionally, the group certification director will conduct random inspections of 10% of the total production areas in the report.