When should you change HEPA filter in cleanroom?

HEPA filters play a critical role in trapping airborne particles and maintaining the purity of the air inside the cleanroom. However, like all air filters, HEPA filters eventually become clogged and need to be replaced. The question then arises, how often should HEPA filters be replaced? Let's find out with Vietnam Cleanroom

HEPA filters are one of the key components of a cleanroom, which plays a critical role in trapping airborne particles and maintaining the purity of the air inside the cleanroom. However, like all air filters, HEPA filters eventually become clogged and need to be replaced. The question then arises, how often should HEPA filters be replaced? Let's find out with Vietnam Cleanroom

Air filters replacement frequency in cleanrooms

HEPA filters are important materials widely used for their effectiveness and flexibility in pharmaceutical production technology to achieve the desired level of cleanliness for each manufacturing process. Therefore, timely maintenance, cleaning, and replacement of filters should be given due attention.

Pre-filter replacement frequency (G1, G2, G3, G4 filters)

The pre-filter should be replaced every six months and should be checked regularly.

The pre filters in the changing rooms should be replaced more often than usual, as people bring more dirt from outside into the gowning room than they did when they put on their cleanroom apparel.

If the primary filters appear to be dirty for a period of fewer than six months, the inspection should be done every 2 to 3 months.

For pre-filters installed in AHUs, they need to be checked and cleaned regularly once a week if used in areas that generate a lot of dust during production or when there are significant pressure fluctuations in the room after a period of use (sharp increase or decrease).

Regular pre-filters cleaning will increase the lifespan of the medium filter installed in the AHU.

Medium filter replacement frequency (F7, F8, F9 filters)

Installed in AHUs and exhaust fan filter boxes, these filters protect the cooling coil from dirt buildup that can cause a loss of cooling efficiency and also retain large dust particles before entering the HEPA filter.

They need to be checked and cleaned every six months. To determine how dirty the filter is, a differential pressure gauge is installed before and after the F8 filter to measure the pressure loss across the filter. This gauge is installed in the AHU for easy and convenient checking.

When the filter is produced, the pressure difference is normally from 200 Pa to 250 Pa.

If the pressure difference is over 400 Pa, it needs to be cleaned by washing it with water and then air-dried or blown clean with compressed air before reinstalling it in the AHU.

When the filter has been cleaned several times and is no longer reusable, it must be removed and a new 100% filter installed.

When the filter is dirty, it should be cleaned immediately, rather than waiting for the scheduled cleaning time.

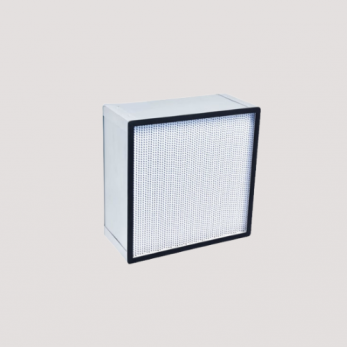

HEPA filter replacement frequency (H13 / H14 filters)

As the HEPA filter removes a variety of particles, its ability to block airflow increases. This forces the blower to raise operating capacity to provide adequate airflow through the high-efficiency filter.

The pressure drop on the filter has a significant impact on the entire cleanroom system.

HEPA filters should be checked once a month. Check the differential pressure before and after the filter. The pressure difference of a new HEPA filter is 200 - 250 Pa.

When the differential pressure reaches 400 Pa, the filter must be checked twice a week. When the differential pressure across the filter reaches 450 - 500 Pa, the HEPA filter should be replaced and a new filter must be installed.

This is applied to all cleanroom classes, including class A, class B, and class C cleanrooms.

In the event that you do not have an accurate measuring device to determine the time to replace the HEPA filter, the HEPA filter is estimated to be replaced within 6-12 months according to the manufacturer's recommendations.

Air filters efficiency optimization

Extending the filter's service life saves maintenance and total expenditures. The longer the filter life, the more fan energy is lost due to particle blockage in the filter. The additional energy cost of airflow passing through a dirty filter is always more than the cost of replacing the filter itself.

Using a filter to its maximum endurance is rarely economically beneficial, let alone the higher chance of contamination associated with the filter's poorer performance. Replace filthy air filters once pressure has been reduced by half from the initial setting to maximize filtration efficiency.

Read more: 3 Factors Affecting The Efficiency Of Fan Filter Unit HEPA Filter

How to clean air filters?

Tools:

- High-pressure water sprayer

- Cleanroom wipes

- Drying cabinet

Cleaning steps:

- Use the water sprayer to rinse the filter surface and aluminum frame until there is no dust remaining on the surface.

- Use a clean cloth to dry the aluminum frame. Arrange the cleaned filters in the drying cabinet.

Drying temperature: 60 - 75°C

Drying time: 2 - 4 hours.

How to replace HEPA filters in cleanroom?

- Bring the cleaned and dried air filter to the required location.

- Gently pull the filter frame to be replaced out of the air return port, avoiding dropping dust onto the floor.

If the filter is being replaced as required, clean around the air return port.

If the filter is being replaced regularly (i.e., there is no frequent replacement requirement), replace both the mask and the filter and clean around the air return port.

- Install the new filter into the air return port slot.

- Check and adjust the seal between the filter frame and the air return port and between the air return port and the ceiling.

- Take the newly replaced filter to the cleaning area and arrange it neatly.