Structure and Material of Dust Filter Bag Frame Filter Cloth

The filter cloth of the dust filter bag frame (or cloth filter bag) typically has an oval or round shape, with a diameter ranging from 130 to 300 mm and a height of 2 to 5 meters. It is made from woven or non-woven fabric.

Depending on the chemical, humidity, temperature of the air flow, and other environmental factors, the filter fabric can be made from materials such as cotton, nylon, polyester, fiberglass, or other suitable materials.

The filter cloth usually has a thickness of around 0.3 mm, while non-woven fabric, often made from synthetic or natural fibers like cotton, typically has a thickness of about 3 to 5 mm. Non-woven fabric is particularly suitable for use in dust filter frames employing the pulse-jet cleaning method.

Textile filters, often woven, typically have a thickness of 1.2 to 5 mm. These woven fabric filters are commonly used in air filtration methods such as shaking or air turning.

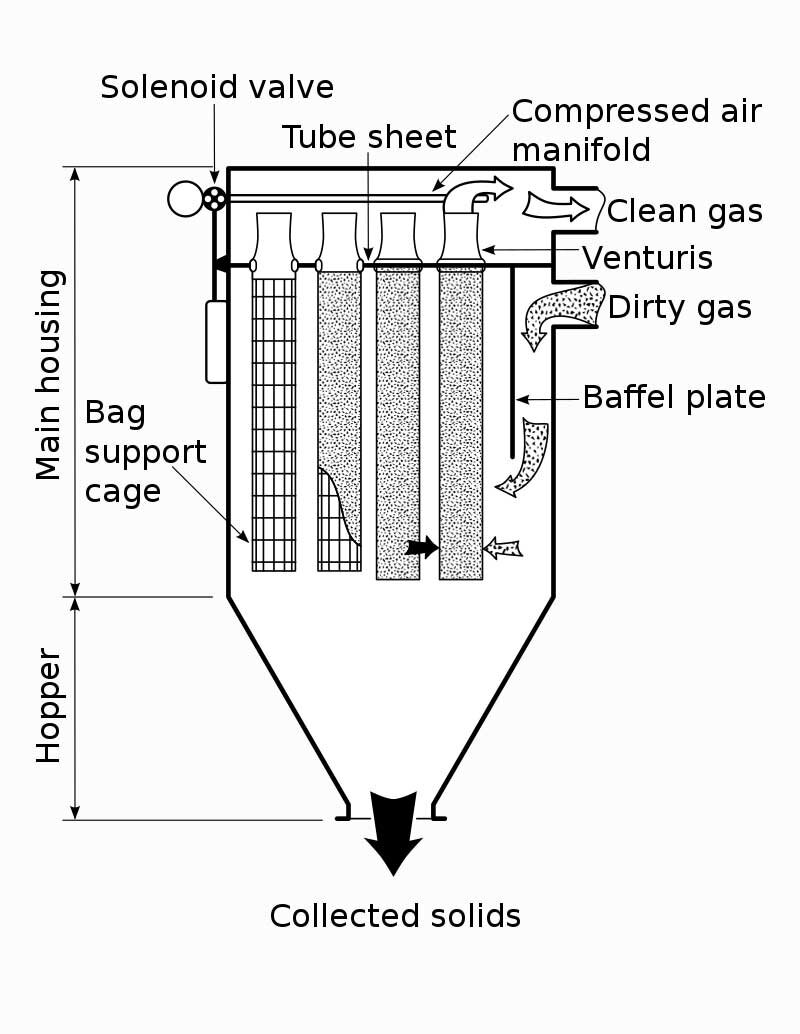

A baghouse filter can accommodate anywhere from dozens to hundreds of filter bags, depending on the system's design and size. When the system is operating, air is pumped inside, causing the fabric bags to stretch around the frame. The distance between the pockets in the system ranges from 30 to 100 mm.

Inside each cloth bag is a metal skeleton, known as the filter bag cage, which helps keep the filter cloth taut during operation. The cage can be disassembled for maintenance or replacement when necessary.

Operating Principle of Dust Filter Bag Frame

The dust filter bag frame uses fabric filter bags arranged in rows and mounted vertically. These are designed to capture dust particles from air flows, separating them and releasing clean air.

The dust flow is typically drawn into the system via an induction blower, through a pipe system. The air passes through the filter bags, while the dust particles are captured on the surface of the filter media, thus separating them from the air. Over time, as dust accumulates and forms a "filter cake" on the surface, various cleaning systems are used to remove dust from the filters.

The cleaning methods for dust filter frames depend on the type of system. The three most common cleaning methods for bag filter equipment are pulse jet, shaker, and air inversion.

In this article, we will present the operating principle of the dust filter bag frame using pulse jets.

- Dust-laden air typically enters from below the bags or filters through the entrance, assisted by the exhaust fan. As the air flow slows, dust particles lose speed and fall into the collection funnel.

- The remaining air is drawn upward through the filters, where the dust is trapped on the outer surface of the filter bags. Clean air passes through to the clean air compartment and exits through the outlet pipe.

- During the filtration process, dust that falls into the bag is transported through the discharge system at the bottom of the bag filter.

Bag-type dust filters typically have a filtration rate of 150-180 m³/h per square meter of filter surface area. With a dust concentration of 30-80 mg/m³, the filtration efficiency reaches up to 96.99%. When the dust concentration exceeds 5000 mg/m³, the air must be pre-filtered before entering the dust filter bag frame.

Factors Affecting the Dust Filtration Process of the Device

Dust Particle Size

Dust particle size has a significant impact on dust filtration efficiency. For particles smaller than 0.3 micrometers, the filter must be designed according to the diffusion mechanism. For larger particles, the air filter should be designed based on the mechanisms of contact and inertial impact. Therefore, the filter cloth size needs to be designed to ensure that dust of varying sizes can be effectively filtered.

Dust Concentration

At low dust concentrations, it takes longer to form a dust layer. Higher dust concentrations tend to increase filtration efficiency more rapidly.

Dust Filter Surface Area

A larger dust filter surface area results in a greater contact area between the dust and the filter cloth, thereby increasing the adhesion of dust particles to the surface of the filter cloth. To increase the contact area, more filter tubes are used, and the diameter of the tubes is reduced.

Pressure Difference

The pressure difference across the bag filter device should not exceed 750-1500 Pa (use a differential pressure gauge with a measuring range of 0-750 Pa to measure the pressure difference of the device) to avoid tearing the filter bag inside.

Air Flow Temperature

Air passes through the filter cloth, which is typically made of synthetic fiber material, so the temperature should be below 250°C. However, fiberglass filter cloth bags can withstand higher temperatures.

Velocity of Airflow

The velocity of the incoming air typically fluctuates between 0.5 and 2 m/s. The bag filter frame is designed to accommodate a series of air streams. An increase in air flow rate leads to higher operating pressure and an increased ratio of air passing through the filter cloth. This increase causes greater mechanical pressure on the filter frames, leading to continuous dust cleaning at high speeds, which can shorten the lifespan of the filter.vv