5 New cleanroom technology trend

In the field of contamination control, cleanroom technology is always advancing. In this article, VCR will delve into the latest advancements in cleanroom technology, covering topics from automation to energy efficiency, and beyond. Read on to learn how these innovations enhance contamination control and establish new benchmarks for excellence.

In the field of contamination control, cleanroom technology is always advancing. In this article, VCR will delve into the latest advancements in cleanroom technology, covering topics from automation to energy efficiency, and beyond. Read on to learn how these innovations enhance contamination control and establish new benchmarks for excellence.

Let's explore five of the latest technological advancements in cleanroom technology.

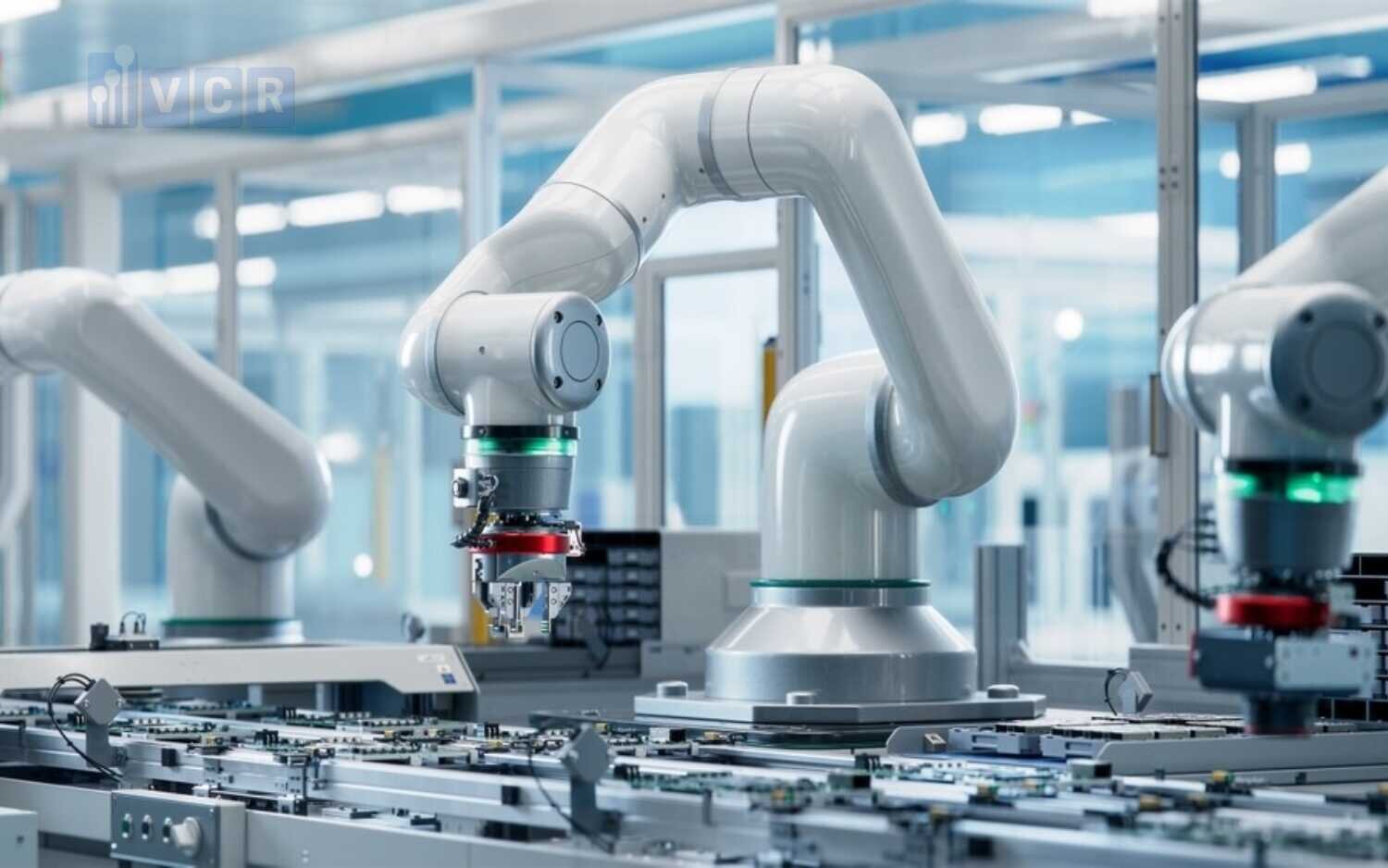

Automated Operations

Automation is revolutionizing cleanroom operations by streamlining processes and reducing the need for manual intervention. This advancement utilizes robotics, intelligent controls, and other automated systems to maximize efficiency and improve precision.

Robotic arms are employed to delicately handle sensitive components, ensuring precision and minimizing the risk of contamination. Automated material handling systems streamline logistics, enabling efficient movement of goods and minimizing downtime.

The integration of automation into cleanroom environments offers manifold advantages. It enhances efficiency by accelerating processes and decreasing cycle times, thereby boosting productivity and cost-effectiveness. Automation also mitigates human error, leading to improved product quality.

Data Monitoring Solutions

Continuous monitoring of data is crucial in cleanroom environments to uphold optimal conditions and promptly detect any deviations. By tracking key metrics in real-time, deviations can be swiftly addressed, minimizing contamination risks and ensuring consistent product quality.

Cutting-edge data monitoring technologies, such as sensors and IoT devices, are transforming data collection in cleanrooms. Sensors precisely gauge essential parameters such as temperature and humidity, and particle levels. IoT devices enable seamless integration and analysis of data, supporting predictive maintenance and ongoing improvement efforts.

Dehumidifiers and Desiccant Systems

Cleanrooms necessitate precise management of environmental conditions, including humidity levels, to maintain optimal operational efficiency and product quality. Elevated humidity can result in issues such as microbial growth, equipment corrosion, and compromised product integrity. Dehumidifiers play a critical role in mitigating these risks by effectively regulating humidity levels within cleanrooms, ensuring a controlled and stable environment.

Modern dehumidifiers are engineered with energy-efficient features, making them cost-effective solutions for controlling humidity in cleanrooms. These advanced units employ technologies like variable-speed compressors, intelligent humidity sensors, and programmable settings to optimize energy consumption while maintaining precise humidity levels.

Energy-Efficient Technologies

There is a growing embrace of sustainable practices and energy-efficient technologies in cleanrooms, aimed at minimizing environmental impact and lowering operational costs. For instance, energy-efficient technologies such as LED lighting and advanced HVAC systems are increasingly favored.

LED lighting not only provides significant energy savings but also boasts a longer lifespan compared to traditional lighting solutions. Meanwhile, HVAC systems equipped with smart controls optimize energy usage by ensuring optimal conditions while minimizing overall energy consumption.

Sustainable Practices

Cleanroom products are increasingly integrating renewable and plant-based materials, aiming to decrease reliance on non-renewable resources and lessen environmental impact. These sustainable materials offer comparable performance while reducing carbon footprint and fostering a more environmentally friendly cleanroom ecosystem.

Many manufacturers of cleanroom equipment are incorporating recycled plastics into their product designs. These plastics are sourced from post-consumer or post-industrial waste, thereby reducing the demand for virgin plastics and diverting waste from landfills.

Furthermore, selecting cleanroom construction materials with low VOC (Volatile organic compound) emissions enhances indoor air quality and environmental health. Opting for paints, adhesives, and sealants with low VOC content minimizes pollution and enhances occupant comfort within cleanroom facilities.