Common errors when using asynchronous FFU

Common errors when using asynchronous FFU often come from the difference in wind speed, pressure and operating time between the devices. This makes the air flow in the clean room unstable, causing cross-contamination and wasting energy. This article will analyze the causes and effective solutions.

- 1. What Is Non-Synchronized FFU?

- 2. Signs That Your FFU System Is Not Synchronized

- 3. Serious Consequences of Using Non-Synchronized FFUs

- 4. Causes of Non-Synchronized FFU Operation

- 5. Solutions to Fix and Prevent Non-Synchronized FFU Issues

- 6. Synchronized FFUs - The Right Solution for High-Demand Industries

- 7. Frequently Asked Questions About Non-Synchronized FFUs

- 8. Need Cleanroom FFU Consultation?

When operating a cleanroom system and ensuring stable air flow, the use of non-synchronous Fan Filter Units (FFUs) can lead to a series of technical problems that affect the performance and life of the equipment. So what are the common errors when using non-synchronous FFUs - from pressure differences, fan speed fluctuations, to unusual noise - and how to effectively prevent them? The following article will help you quickly identify common signs, analyze common causes, and provide appropriate solutions when FFUs operate non-synchronously.

1. What Is Non-Synchronized FFU?

What is an FFU?

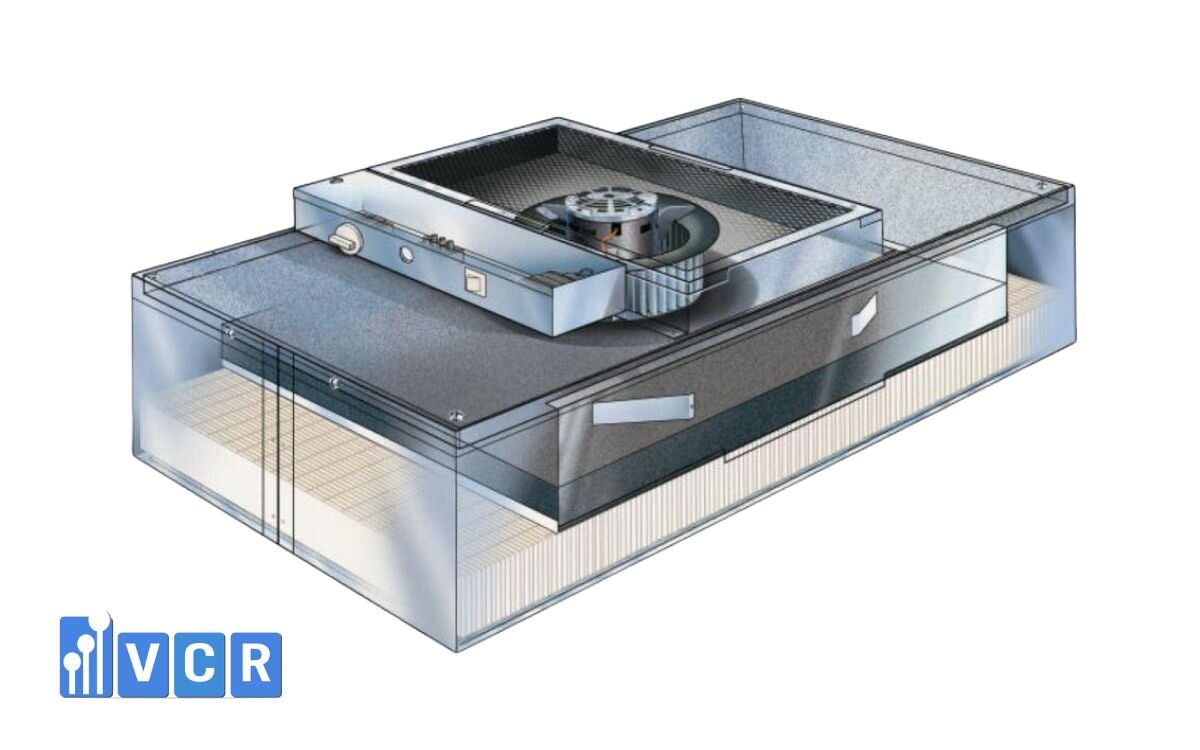

An FFU (Fan Filter Unit) is an air filtration device integrated with a fan, installed on cleanroom ceilings to create unidirectional laminar airflow. It pushes air through a HEPA/ULPA filter to remove airborne particles and microorganisms.

FFUs are widely used in industries that require high levels of cleanliness, such as:

Pharmaceutical manufacturing (GMP)

Electronics and semiconductor assembly (ISO 5-6)

High-end cosmetics and food production

What is a synchronized FFU system?

A synchronized FFU system means:

- Air velocity across all FFUs is uniform

- Output pressure is balanced and harmonized

- All FFUs are operated according to pre-set programs via a central control system

Such a system ensures stable airflow, energy efficiency, and optimal filtration performance.

Non-synchronized FFU - A common scenario

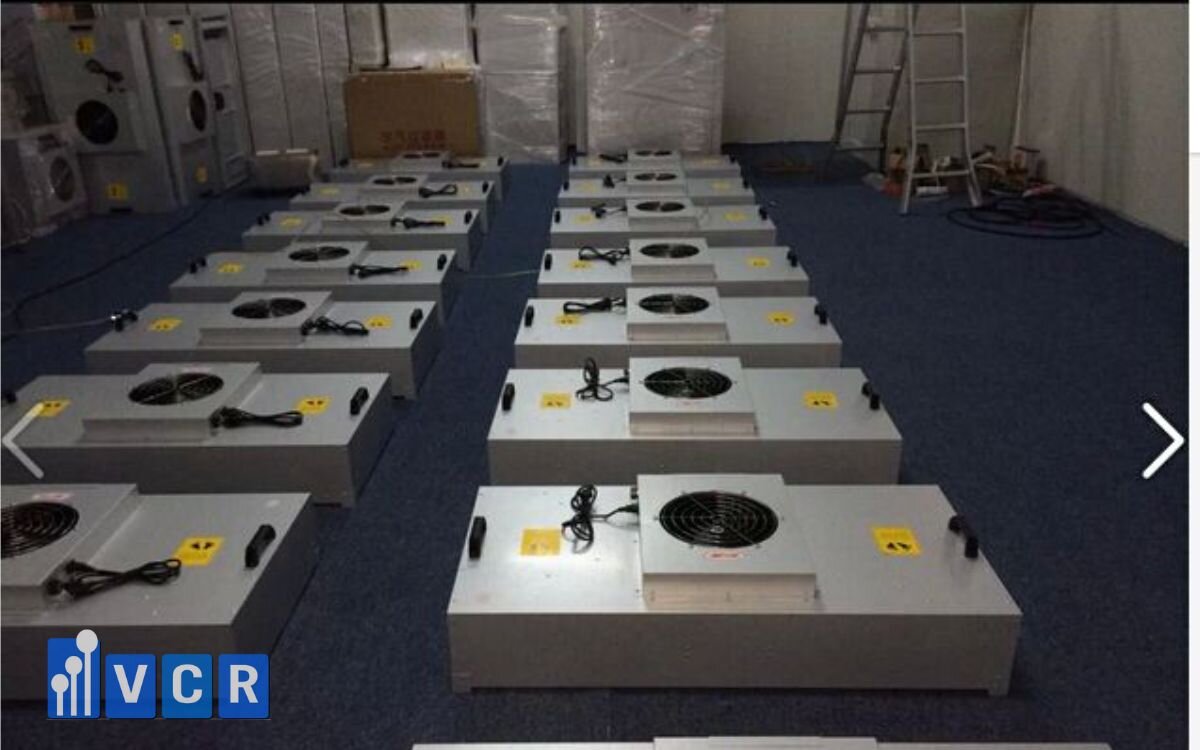

In practice, many factories operate with non-synchronized FFUs, especially when:

- Units are installed in phases and sourced from different suppliers

- No central control system is implemented

- The system is not inspected regularly over time

Common signs include:

Some FFUs produce louder noise than others

Uneven or swirling airflow in some areas

Perceptible “inconsistency” in air velocity across the room

These symptoms indicate the airflow is no longer stable, which may severely impact cleanroom performance.

See more: What is AHU? Structure and operating principle of AHU system

2. Signs That Your FFU System Is Not Synchronized

When FFUs are not synchronized, abnormal conditions soon appear, compromising the cleanroom environment. Here are the most common signs observed by technicians and QA/QC teams:

1. Uneven airflow - turbulent zones appear

A standard ISO cleanroom requires stable, evenly distributed laminar airflow. If FFUs are not synchronized:

- Some zones experience high air velocity while others are weak

- Turbulent airflow may develop

- Temperature differences may be felt in different areas of the room

2. Unstable pressure differential between rooms

Cleanrooms rely on pressure differentials to control airflow direction and prevent cross-contamination. Non-synchronized FFUs may cause:

- Imbalance in room-to-room pressure (e.g., airlocks, weighing rooms, critical zones)

- Positive or negative pressure drifting from the setpoint

- Doors becoming hard to open/close due to pressure abnormalities

3. Increased airborne particles - localized cross-contamination risk

When airflow speed and pressure are inconsistent:

- Reversal of airflow may occur, drawing particles and microbes backward

- Floating particles are not fully pushed down to return vents

- Particle accumulation in corners, door frames, or wall-floor junctions is common

This is especially dangerous in pharmaceuticals and food production, where even minor contamination may result in GMP violations.

4. Noise or vibration from FFUs

FFUs are typically quiet. However, with non-synchronized operation, you may hear:

- Louder noise from certain units

- Ceiling vibration when multiple FFUs run at inconsistent speeds

- Uneven or fluctuating fan sound

This indicates an urgent need for maintenance, as internal motors or speed controllers may be malfunctioning.

See more: The importance of humidity control in cleanroom

3. Serious Consequences of Using Non-Synchronized FFUs

Non-synchronized FFUs not only reduce operational efficiency but also pose serious risks to cleanroom quality and production safety.

|

Issue |

Impact on Cleanroom |

|

Turbulent airflow |

- Swirling, uneven airflow - Reduced HEPA efficiency - Lower ISO cleanroom classification, risk of particle count exceeding limits |

|

Increased energy consumption |

- Some FFUs overcompensate to balance pressure - Efficiency loss, wasted energy - Shortened motor and controller lifespan |

|

Cross-contamination risk |

- Reversed airflow in weak zones - Particles and microbes may recirculate - Critical in GMP-regulated industries such as pharma and food |

|

Pressure imbalance |

- Loss of proper pressure gradient - Air leakage through gaps and door frames - May lead to equipment damage due to abnormal pressure load |

These consequences may not appear immediately, but they accumulate over time, significantly degrading cleanroom stability-particularly in GMP or ISO 14644 compliant environments.

4. Causes of Non-Synchronized FFU Operation

FFU systems are only effective when all units operate with consistent parameters. In reality, many facilities face non-synchronization issues due to the following reasons:

1. Mixing different FFU brands or models

Each brand varies in fan blade design, motor type, controller, and airflow specifications

Even with similar sizes, differences in performance create inconsistent output

This disrupts overall airflow dynamics

Recommendation: Use the same brand and model for all FFUs in a zone. If replacements are needed, do so in batches or by cluster

2. No central control unit (CCU)

Many systems use standalone switches or simple wiring

Lack of centralized control means:

- Airspeed, timing, and operating modes are not unified

- Deviations in performance go undetected

Solution: Implement a centralized FFU control system (can include remote monitoring, real-time alerts)

3. HEPA filter age or condition mismatch

A clogged HEPA filter increases resistance, forcing fans to work harder or become inefficient

Causes imbalance in airflow among units

Suggestion: Plan coordinated HEPA replacements by cluster, not individually.

4. No periodic calibration

Over time, components wear out and dust buildup alters performance

Without routine calibration, system balance degrades

GMP recommendation: Calibrate FFU systems every 6-12 months, especially for pharma or ISO 5-6 cleanrooms.

See more: Comparing airlflow standards: ISO 14644 vs ASHRAE

5. Solutions to Fix and Prevent Non-Synchronized FFU Issues

To ensure stable FFU operation and optimal filtration performance in cleanroom environments, the following technical solutions should be implemented consistently:

1. Use FFUs with matching specifications and from the same manufacturer

Prioritize using the same model and supplier across the entire cleanroom zone

Ensure all FFUs share the same:

- Rated airflow (m³/h)

- Fan speed

- HEPA/ULPA filter efficiency

This minimizes the risk of operational discrepancies from the design phase.

2. Implement a central control system (Master Control Unit)

Allows programming and synchronization of airspeed, pressure, and operational time for all FFUs

Enables easy device status monitoring via supervisory software

Can be integrated with alarms for parameter deviation

Some control systems support integration with BMS or SCADA-ideal for GMP or ISO-compliant facilities.

3. Schedule maintenance and replace HEPA filters in batches

FFUs should be routinely checked for:

- Filtration performance

- Filter clogging level

- Fan speed

HEPA filters should be replaced in batches or by zone to avoid resistance imbalance caused by uneven filter conditions.

4. Monitor airflow using sensors and software

Use airflow sensors and differential pressure sensors to:

- Detect abnormal zones (e.g., weak airflow, pressure deviation)

- Automatically adjust fan speeds to maintain consistent airflow

Monitoring software allows real-time tracking, reporting, and operational trend analysis.

This is an advanced solution enabling the cleanroom to "self-balance" over time-particularly beneficial for pharmaceutical, semiconductor, and ISO 5-6 production facilities.

6. Synchronized FFUs - The Right Solution for High-Demand Industries

In modern manufacturing sectors, simply installing FFUs is not enough to maintain a compliant cleanroom environment. The FFUs must be synchronized-from airflow rates to real-time operations-to ensure absolute stability under stringent requirements.

Industries That Require Synchronized FFUs

1. Pharmaceuticals - strict GMP compliance

Cleanrooms in pharma must tightly control airflow, pressure, and microbiological contamination

Any cross-contamination may result in GMP violations or product recalls

Synchronized FFUs help:

- Maintain differential pressure between zones (e.g., weighing rooms, airlocks, packaging areas)

- Distribute airflow evenly in operating zones

2. Semiconductors and electronics - ultra-clean ISO 5-6 environments

- Production processes are highly sensitive to static electricity and nanoscale particles

- FFUs must operate uniformly to maintain unidirectional airflow

Non-synchronized FFUs can cause product defects or lower yield rates.

3. High-end cosmetics - visual and contamination control

- Filling and packaging lines require a dust-free, odor-free cleanroom environment

- Synchronized FFUs help reduce turbulence and the risk of microdust or fiber contamination

Solution: Centralized Control FFU System - Total Synchronization

Modern systems now integrate centralized control units that offer:

|

Function |

Specific Benefit |

|

Synchronized fan speed |

Ensures all FFUs run at the same speed - consistent airflow |

|

Zone control |

Easily divide control by functional area |

|

Error detection & alerts |

Identify FFUs with speed deviation, shutdown, or overload |

|

BMS/SCADA integration |

Connects to smart factory operation systems |

7. Frequently Asked Questions About Non-Synchronized FFUs

1. Can I use different types of FFUs in the same cleanroom?

→ Not recommended.

Mixing FFUs from different manufacturers can lead to discrepancies in:

- Airflow output

- Filter resistance

- Fan speed

This causes airflow imbalance, turbulence zones, and may compromise ISO classification and filtration effectiveness.

2. How often should FFU synchronization be checked?

→ Every 6 months on average or according to the cleanroom's maintenance schedule.

Regular checks help:

- Detect FFUs operating out of spec

- Rebalance the airflow system

- Ensure consistent performance-especially critical in pharma and electronics sectors

3. Can non-synchronized FFUs damage equipment?

→ Yes.

Potential consequences include:

- Ceiling vibrations weakening FFU mounting

- Local pressure imbalances causing fans or filters to operate beyond spec

- Premature FFU failure or reduced filtration performance

Repair costs often exceed the cost of routine inspections.

8. Need Cleanroom FFU Consultation?

Don’t let non-synchronized FFUs reduce your facility’s performance and cleanroom classification.

Inspect - Calibrate - Synchronize your entire FFU system with the VCR technical team.

We provide:

- Tailored centralized FFU control solutions by industry

- GMP, ISO 14644 compliance

- Full technical support and consultation

Contact VCR now for a free consultation.

Hotline: 090.123.9008

Email: [email protected]

Website: https://vietnamcleanroom.com/

Diep VCR