What is prerequisite program? Prerequisite Program for HACCP system

The HACCP prerequisite program includes the fundamental principles of food safety and general hygiene conditions for food production business establishments.

In the article below, let's explore with Vietnam Cleanroom Equipment what the HACCP prerequisite program is and what its content includes.

Prerequisite Program

What is Prerequisite Program?

The Prerequisite Program (PRP) is a program applied alongside HACCP.

PRP includes basic food safety principles as well as issues regarding hygiene conditions. It helps minimize risks in the production and business processes to ensure food safety and hygiene.

Read more: What is OPRP?

Equivalent standards

- ISO/TS 22002-1:2009 Food manufacturing

- ISO/TS 22002-2:2013 Food supply (Catering)

- ISO/TS 22002-3:2011 Farming

- ISO/TS 22002-4:2013 Food packaging manufacturing

- ISO/TS 22002-5:2019 Transport and storage

- ISO/TS 22002-6:2016 Feed production

Scope of Application for the Prerequisite Program

The HACCP prerequisite program is used throughout the entire process, from the harvesting of raw materials to the consumption of the product. Different environments will have customized prerequisite programs that are appropriate for their specific needs.

Read more: HACCP Cerfiticate

How importantn is HACCP prerequisite program?

The importance

Building HACCP on the foundation of the prerequisite program is essential for ensuring that food is produced in a safe environment.

Prerequisite programs provide the basic operational conditions and environment necessary to produce safe, high-quality food. Federal, state, and local regulations and policies establish many of these conditions and practices.

The existence and effectiveness of prerequisite programs must be assessed during the design and implementation of the HACCP plan. All prerequisite programs must be documented and reviewed regularly.

Prerequisite Program's roles

- Provides the foundation for the overall HACCP plan, helping to address specific risk issues in the food processing process.

- Forms the basis for an effective HACCP system.

- Facilitates the necessary basic production environment and ensures safe and healthy production operations. PRPs are always thoroughly documented and monitored to ensure that employees and visitors comply with regulations.

- Properly implemented PRPs can help minimize risks affecting the production facility and food safety and hygiene quality.

HACCP Prerequisite Program checklist

- Equipment calibration procedures

- Effective maintenance program

- Cleaning and sanitation program

- Water safety procedures/ Water treatment procedures

- Structure and layout of the facility

- Waste management

- Pest control activities

- Personnel hygiene and employee health

- Food safety staff training

- Raw material production and receiving (includes temperature control)

- Layout zoning

- Supplier control

- Stock control

- Recall and traceability

- Allergen control program

- Audits and inspections

- Product labelling and packaging materials

Read more: Temperature and humudity in cleanroom

Standards Requiring Implementation of Prerequisite Programs

- HACCP Standard: The prerequisite program for the HACCP standard is the SSOP (Sanitation Standard Operating Procedures).

- FSSC 22000 Standard: The mandatory PRP is ISO/TS 22002.

- ISO 22000 Standard: Under the management of the International Organization for Standardization (ISO). ISO 22000:2018 mentions PRPs, but the content is not clearly defined.

Prerequisite Condition Controls

Different conditions are needed to effectively control the PRPs:

- How do prerequisite programs ensure food is produced safely?

- Who is responsible for checking if the prerequisite program remains under control?

- What actions will be taken when an issue arises?

- What documents must be stored for the prerequisite programs?

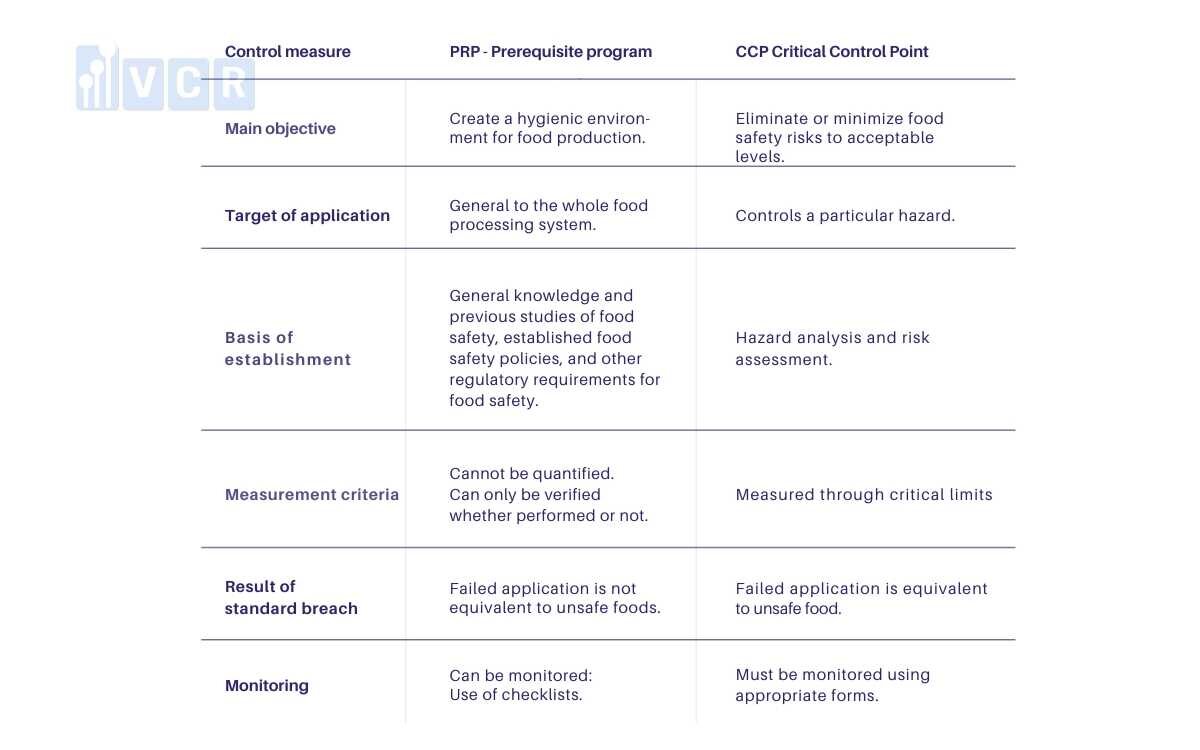

Comparison between PRP and CCP

Similarities: PRP (Prerequisite Programs) and CCP (Critical Control Points) both support the HACCP system.

Differences: